Blog

- Home

- Blog

Top 10 Industrial Pumps You Need to Know for Optimal Performance

In the realm of industrial operations, the efficiency and reliability of processes heavily depend on the performance of Industrial Pumps. According to a recent report by Allied Market Research, the global industrial pump market was valued at approximately $60 billion in 2020 and is expected to reach $89 billion by 2030, growing at a CAGR of 4.3%. The increasing demand for water and wastewater management, along with rising investments in infrastructure, play a crucial role in this expansion. Understanding the various types of industrial pumps and their applications is vital for ensuring optimal performance in manufacturing and production environments.

Dr. Michael Hayes, a noted expert in fluid dynamics and pump technologies, emphasizes the significance of selecting the right industrial pump for specific applications. He states, “The efficiency of an industrial system is often dictated by the performance of its pump; neglecting proper selection and maintenance can lead to significant operational losses.” Thus, identifying the top industrial pumps suitable for different operational needs is essential not just for maximizing productivity but also for ensuring long-term sustainability within industries ranging from manufacturing to chemical processing. This guide will explore the top 10 industrial pumps that are indispensable for achieving superior performance in today's competitive landscape.

Top 10 Industrial Pumps for Enhanced Operational Efficiency

When it comes to boosting operational efficiency in industrial settings, selecting the right pump is crucial. Industrial pumps play a pivotal role in various processes, from water management to chemical handling. Understanding the different types of pumps available can help streamline operations, reduce downtime, and enhance overall productivity.

Tips: Prioritize choosing pumps that are designed for the specific fluids you are handling, as this can prevent premature wear and costly repairs. It’s also beneficial to consult with industry experts to ensure your system is optimized for your unique operational demands.

Additionally, consider the energy efficiency of the pumps you implement. Modern pumps come equipped with advanced technology that not only reduces energy consumption but also minimizes maintenance costs. Regular monitoring and maintenance practices can further prolong the lifespan of these pumps and maintain their efficiency.

Tips: Implement a routine maintenance schedule that includes inspections and prompt repairs. This proactive approach ensures that any potential issues are addressed before they escalate, keeping your operations running smoothly.

Top 10 Industrial Pumps for Enhanced Operational Efficiency

Understanding Different Types of Industrial Pumps and Their Applications

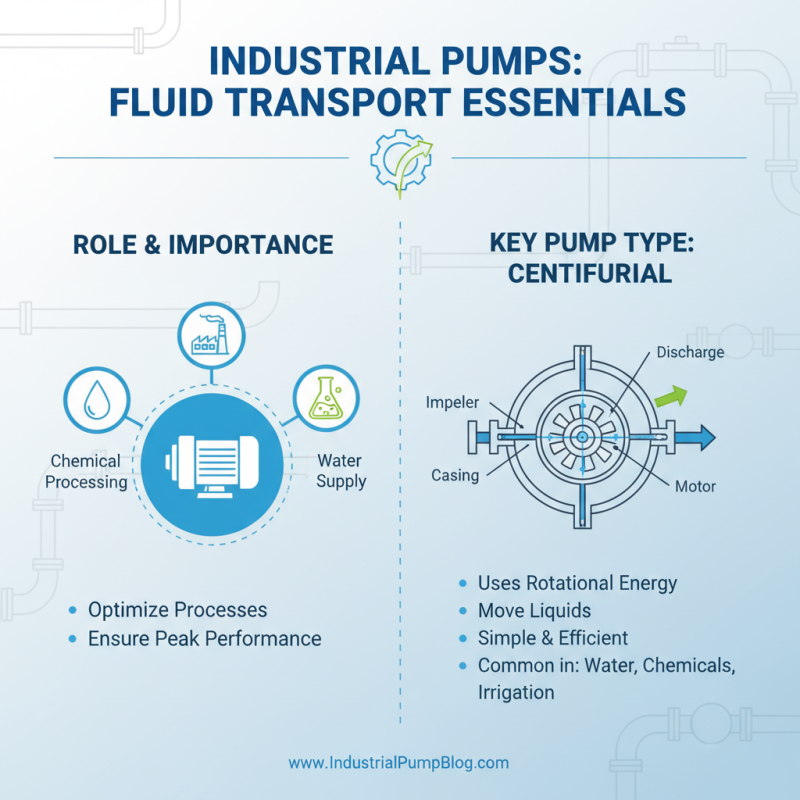

Industrial pumps are essential components across various sectors, serving to efficiently transport fluids vital for numerous applications. Understanding the different types of industrial pumps allows for better optimization of processes, ensuring that systems operate at peak performance. Centrifugal pumps, for example, are widely used in water supply and chemical processes, utilizing rotational energy to move liquids. Their simplicity and efficiency make them suitable for a range of tasks, from irrigation to industrial cooling systems.

On the other hand, positive displacement pumps are another category worth noting, particularly for applications requiring high pressure and precise flow rates. These pumps work by trapping a fixed amount of fluid and forcing it through the discharge, making them ideal for transferring viscous fluids such as oils and slurries. Additionally, diaphragm pumps offer versatility and can handle corrosive substances, making them a favorite in industries like pharmaceuticals and food processing. Each pump type has unique attributes tailored to specific needs, highlighting the importance of selecting the right pump to ensure reliability and efficiency in industrial operations.

Key Performance Metrics for Evaluating Industrial Pumps

When evaluating industrial pumps for optimal performance, key performance metrics play a crucial role in ensuring the right choice for specific applications. One of the foremost metrics is flow rate, which indicates the volume of fluid a pump can handle per unit of time. A higher flow rate is generally preferred for applications requiring the rapid movement of large volumes, while a lower flow rate might be sufficient for more precise processes. Additionally, understanding the pump's head—defined as the height the pump can raise the fluid—is essential for determining its efficiency in overcoming system resistance and delivering fluid to the desired location.

Another critical performance metric is efficiency, which measures how effectively a pump converts energy into fluid movement. High efficiency reduces energy consumption and operational costs, making it a vital consideration in long-term industrial applications. Similarly, the Net Positive Suction Head (NPSH) available and required are important for preventing cavitation, which can damage pumps and reduce their lifespan. Monitoring these metrics allows engineers and operators to select pumps that not only meet the specific needs of their systems but also enhance reliability and sustainability in their operations.

Factors Influencing Pump Selection in Industrial Operations

When selecting industrial pumps for optimal performance, several key factors come into play, significantly influencing the operational efficiency and longevity of these critical components. One major consideration is the fluid characteristics, including viscosity, temperature, and corrosiveness. According to the Hydraulic Institute’s standards, over 60% of pump failures can be attributed to improper selection based on fluid properties. Thus, understanding the specific requirements of the fluid helps in choosing the right type of pump and materials that can withstand such conditions.

Additionally, the application type determines the pump selection process. For instance, processes involving high solids content require pumps designed for robust handling, such as positive displacement pumps, to ensure continuous operation without blockages. A report by the American Society of Mechanical Engineers highlights that industries dealing with wastewater, mining, and agriculture often see efficiency gains of up to 30% when the appropriate pump type is utilized. Furthermore, factors like energy efficiency ratings and maintenance requirements are crucial; opting for pumps with high-efficiency motors can lead to significant energy cost savings, as noted in the U.S. Department of Energy's guidelines, where energy-efficient pumps can reduce operational costs by approximately 20-50%.

Latest Innovations and Trends in Industrial Pump Technology

In the rapidly evolving field of industrial pump technology, staying abreast of the latest innovations is essential for optimal performance. One of the most notable trends is the integration of IoT (Internet of Things) technology into pump systems. According to a recent report by Global Market Insights, the adoption of smart pumps is expected to reach a market value of $5.5 billion by 2026, driven by their ability to enhance operational efficiency and provide real-time monitoring capabilities. These pumps not only help in reducing downtime but also enable predictive maintenance, thereby increasing productivity.

Another significant advancement is the development of materials designed to withstand extreme conditions. Recent research highlighted in the Journal of Industrial Engineering shows that pumps constructed from advanced composites and corrosion-resistant alloys can significantly extend service life. This innovation is particularly critical in sectors such as oil and gas, where pumps are subject to harsh environments.

Tips: To maximize the benefits of these trends, consider investing in training for your team on the latest pump technologies. Regularly updating your knowledge base on materials and designs can lead to better maintenance practices and enhanced overall performance. Furthermore, assessing your current systems for integration possibilities with IoT technology can streamline operations and provide insights that were previously unattainable.

Top 10 Industrial Pumps You Need to Know for Optimal Performance - Latest Innovations and Trends in Industrial Pump Technology

| Pump Type | Flow Rate (GPM) | Power (HP) | Efficiency (%) | Latest Innovations |

|---|---|---|---|---|

| Centrifugal Pump | 100-200 | 10-15 | 85 | Smart monitoring systems |

| Positive Displacement Pump | 50-150 | 5-20 | 90 | Variable speed drives |

| Submersible Pump | 10-500 | 1-30 | 75 | Integrated floating system |

| Diaphragm Pump | 5-200 | 1-10 | 80 | Leak-free technology |

| Slurry Pump | 20-300 | 5-20 | 78 | Wear-resistant materials |

| Magnetic Drive Pump | 10-250 | 2-15 | 87 | No shaft seal technology |

| Peristaltic Pump | 1-100 | 0.5-5 | 95 | Flexible tube technology |

| Vacuum Pump | 10-100 | 1-10 | 80 | Energy-efficient models |

| Gear Pump | 5-200 | 2-15 | 85 | Enhanced durability design |

| Hydraulic Pump | 10-400 | 3-25 | 88 | Smart control systems |

Related Posts

-

7 Best Industrial Pumps You Should Consider for Your Next Project

-

Exploring the Innovations in Industrial Pumps: How Cutting-Edge Technology is Revolutionizing Efficiency

-

Top Strategies for Sourcing High Performance Industrial Pumps Globally

-

Ultimate Guide to Selecting the Right Industrial Dosing Pump for Your Needs

-

How to Choose the Best Chemical Pumps for Your Industrial Needs

-

Exploring the Latest Innovations in Pump Products: Enhancing Efficiency and Sustainability