Blog

- Home

- Blog

2026 Top High Pressure Plunger Pump Applications and Benefits?

In 2026, High Pressure Plunger Pump technology continues to evolve. These pumps are vital in various industries, delivering fluids at intense pressures. Their adaptability allows for numerous applications, including automotive, cleaning, and water jet cutting.

High Pressure Plunger Pumps offer substantial benefits. They provide efficiency and reliability. Yet, the complexity of these systems can pose challenges. Understanding their mechanics is crucial for optimal performance. In rigorous environments, even minor errors can lead to failures.

As industries strive for innovation, the demand for High Pressure Plunger Pumps grows. Companies that invest in this technology often see significant returns. However, there is always room for improvement. Continuous training and feedback can enhance pump operation and maintenance practices.

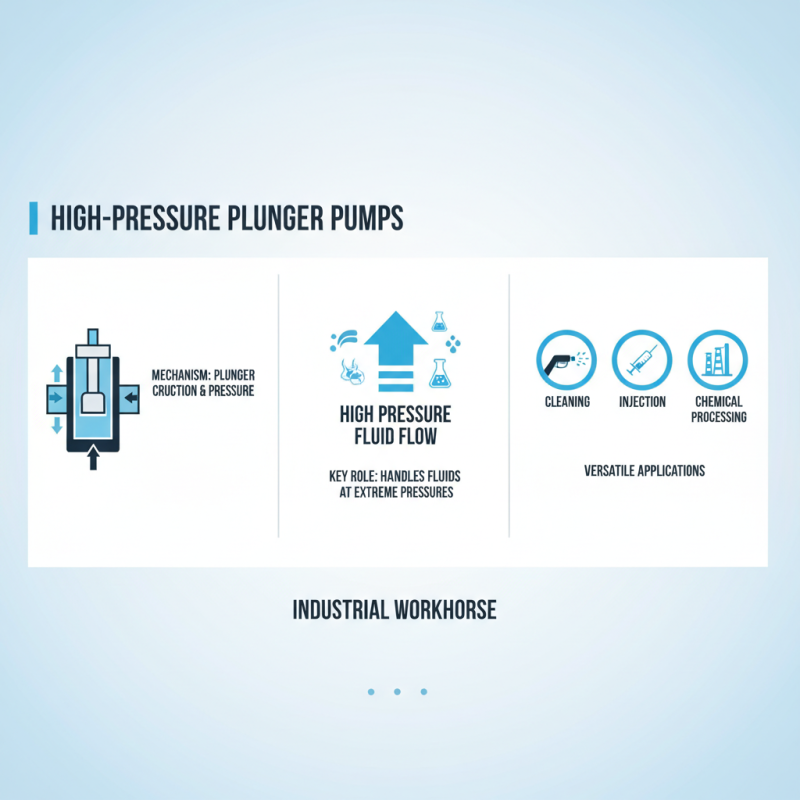

Overview of High Pressure Plunger Pumps and Their Mechanism

High pressure plunger pumps play a crucial role in various industries. They are designed to handle fluids at high pressures, making them versatile in applications like cleaning, injection, and chemical processing. The mechanism of these pumps is relatively straightforward. A plunger moves back and forth, creating suction and discharge cycles. This movement pressurizes the fluid, enabling it to flow at high rates.

One notable feature of high pressure plunger pumps is their efficiency. The design minimizes fluid leaks, which is essential in many applications. However, this efficiency can also lead to operational challenges. For instance, if not maintained properly, wear and tear can affect performance. Regular checks and timely maintenance are necessary to avoid downtime.

These pumps are versatile but not without limitations. For example, they can struggle with highly viscous fluids. In such cases, alternative pump types may be more suitable. Understanding these strengths and weaknesses is vital for users aiming to maximize the pump's potential.

Key Applications of High Pressure Plunger Pumps in Various Industries

High pressure plunger pumps are key players in various industries today. Their ability to generate and sustain high pressures makes them essential in cleaning, spraying, and surface preparation applications. In the oil and gas sector, these pumps are crucial for enhanced oil recovery. According to a recent industry report, around 72% of oil extraction methods now incorporate advanced pump technologies, showing a rising trend towards efficiency.

In the construction industry, high pressure plunger pumps facilitate tasks such as concrete spraying and surface cleaning. A report from the Construction Equipment Journal indicates that construction machinery using these pumps has increased productivity by up to 35%. These pumps also find use in food processing. They ensure thorough cleaning and sanitization of equipment, which is paramount for food safety.

However, like any technology, high pressure plunger pumps have limitations. Maintenance can be challenging; if not properly serviced, they can lead to costly downtime. Additionally, the initial installation costs may deter some industries. Balancing cost against performance is a continuous conversation among engineers. As industries evolve, the conversation around high pressure plunger pump efficiency will need to address these challenges more directly.

Benefits of Using High Pressure Plunger Pumps for Industrial Processes

High pressure plunger pumps are crucial for many industrial processes. Their efficiency can significantly impact production outcomes. Reports indicate that these pumps can operate at pressures exceeding 40,000 psi. This capacity allows for precise fluid handling in applications like injection molding and waterjet cutting.

The benefits of using high pressure plunger pumps are manifold. They provide consistent flow rates and high reliability, essential for any manufacturing task. A study highlighted that companies using these pumps experienced a 20% reduction in downtime. Moreover, they contribute to energy savings, reducing operational costs. This can be crucial in competitive markets where margins are thin.

However, it’s not all seamless. Regular maintenance is necessary to ensure optimal performance. Even with advanced technology, wear and tear can lead to inefficiencies. Some users report challenges in integrating these pumps into existing systems. Addressing these issues requires careful planning and investment in training. Ultimately, while high pressure plunger pumps are valuable, thoughtful implementation is key to maximizing their benefits.

Comparative Analysis of High Pressure Plunger Pumps vs. Other Pump Types

High pressure plunger pumps stand out when compared to other pump types. They excel in applications requiring intense pressure and precise fluid delivery. For example, when a high flow rate and consistent performance are vital, these pumps shine. They are ideal for cleaning, painting, and industrial processes. Their straightforward design often leads to fewer mechanical failures, enhancing reliability.

Conversely, centrifugal pumps can experience efficiency losses at high pressures. They work best in low-viscosity fluids. This limits their applications. The high pressure plunger pump, however, handles a wider range of substances. This versatility can boost operational efficiency in various industries. Yet, it's important to consider the energy costs associated with these pumps. Sometimes, they are not the most energy-efficient option available.

Moreover, while high pressure plunger pumps are robust, they may require more maintenance. Regular checks are needed to ensure longevity. Users might find that balancing maintenance with operational demands is challenging. Evaluating the specific application requirements before selecting a pump type is essential for optimal performance.

2026 Top High Pressure Plunger Pump Applications and Benefits

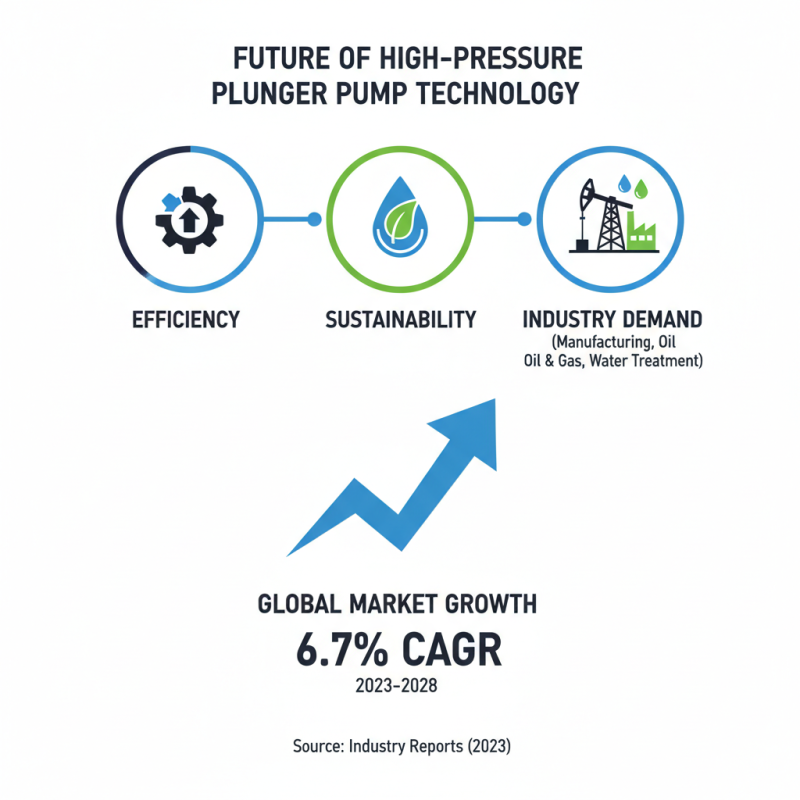

Future Trends and Innovations in High Pressure Plunger Pump Technology

The future of high-pressure plunger pump technology is evolving rapidly. Innovations are focusing on efficiency and sustainability. According to recent industry reports, the global market for high-pressure pumps is anticipated to grow at a CAGR of 6.7% from 2023 to 2028. This rise is driven by increased demand in industries like manufacturing, oil and gas, and water treatment.

Emerging materials and designs improve pump reliability. Lightweight, corrosion-resistant materials reduce maintenance needs. Moreover, advanced monitoring systems enable real-time performance tracking. These technologies can predict failures before they occur. However, businesses must invest in training to utilize these advanced features effectively.

**Tip:** Regular maintenance can extend pump life significantly. Even minor inspections can prevent costly breakdowns.

Manufacturers are also exploring smart technology integration. IoT-enabled pumps provide valuable data insights. Still, some businesses remain hesitant to adopt these technologies due to initial costs.

**Tip:** Research potential ROI before making high-tech investments. Understand the long-term benefits. Remember, innovation involves ongoing learning.

Related Posts

-

How to Choose the Right High Pressure Pump for Your Industrial Needs

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications

-

5 Best Tips for Choosing the Right Hydraulic Pump for Your Needs

-

Top 10 Industrial Pumps You Need to Know for Optimal Performance

-

2026 Best Diaphragm Dosing Pump What to Look For?

-

5 Essential Tips for Sourcing the Best Pump Water Solutions Globally