Blog

- Home

- Blog

Top 10 Metering Pumps for Accurate Fluid Control in Various Industries

In today’s rapidly evolving industries, precision in fluid control is paramount. Metering pumps stand at the forefront of this technology, ensuring accurate and consistent dosing in various applications. Expert Richard Hale, a specialist in fluid dynamics, once stated, “The right metering pump can transform operational efficiency.” This emphasizes the crucial role these pumps play in modern processes.

Metering pumps provide exceptional reliability, making them indispensable in sectors such as pharmaceuticals and chemical processing. These devices offer precise flow rates, which can significantly impact product quality. However, choosing the right metering pump is not always straightforward. Each application demands careful consideration of various factors, including fluid properties and environmental conditions.

Yet, many industries still face challenges in achieving optimal performance. Common issues include wear and tear, calibration errors, and maintenance neglect. Striving for perfection in metering systems is a continuous journey. The right metering pumps can mitigate many of these concerns, but we must also acknowledge our responsibility to understand their limitations. This balance between technology and human oversight is essential for long-term success.

Overview of Metering Pumps and Their Importance in Fluid Control

Metering pumps play a vital role in fluid control across various industries. These pumps precisely dispense liquids, ensuring consistency and accuracy. Their importance cannot be overstated. In sectors like pharmaceuticals, food and beverage, and water treatment, precise dosing is crucial. Improper fluid control can lead to costly mistakes and safety hazards.

When choosing a metering pump, consider the type of fluid you are working with. Viscosity, temperature, and chemical compatibility are key factors. If the pump cannot handle the fluid, it risks failing. Regular maintenance is also essential. Without it, performance can decline over time.

**Tips:** Regularly check for leaks to ensure system integrity. Adjust pump settings based on real-time needs. Understanding your pump’s specifications is critical for optimum performance. Remember, experimenting with settings can lead to unexpected results, so proceed with caution. Ultimately, investing time in these processes will enhance your overall efficiency.

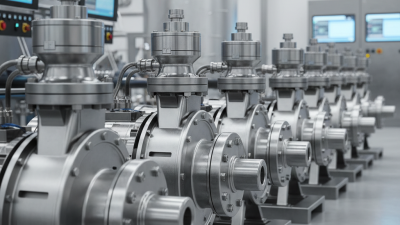

Types of Metering Pumps Used Across Different Industries

Metering pumps play a critical role in industries such as water treatment, pharmaceuticals, and food processing. These pumps ensure precise fluid control, which is vital for maintaining product quality and safety. According to a report by MarketsandMarkets, the global metering pump market is expected to reach $7.76 billion by 2024, reflecting a robust demand in various sectors.

In water treatment, diaphragm pumps are popular. They offer accuracy and reliability when handling corrosive chemicals. In pharmaceutical manufacturing, peristaltic pumps are favored. They minimize contamination risks by allowing fluid transfer without contact. Additionally, screw pumps are often used in food and beverage applications due to their capability to handle viscous fluids.

Tips: Always consider the fluid characteristics. The choice of pump type directly impacts performance. Regular maintenance is essential to prevent breakdowns. Each pump has its weaknesses, such as wear over time or pressure fluctuations. Evaluate these limitations regularly to ensure optimal operation across different settings.

Top 10 Metering Pumps for Accurate Fluid Control in Various Industries

This chart illustrates the distribution of various types of metering pumps commonly used across different industries, showcasing their respective application percentages.

Key Features to Consider When Selecting a Metering Pump

When selecting a metering pump, several critical features should guide the decision-making process. Accuracy is a paramount concern in various industries, including chemical, food, and pharmaceuticals. According to a recent industry report, a metering pump's precision can vary by as much as 5%, depending on the design and materials used. A pump with high resolution ensures that processes remain efficient, reducing waste and operational costs.

Another essential aspect is the pump's compatibility with different fluids. Many applications require pumps that handle corrosive or viscous substances. A study found that nearly 30% of pump failures stem from material incompatibility. Therefore, examining the materials of construction becomes crucial. Additionally, consider the flow rate and pressure output. Reports indicate that an appropriate flow rate can enhance production efficiency by up to 15%.

Lastly, maintenance requirements often get overlooked but are vital to long-term functionality. Many pumps demand regular checks and servicing, which can add to operational downtime. Simplifying maintenance procedures enhances reliability. It reflects that even small design flaws in pumps can lead to significant performance dips over time. Choosing wisely based on these features ensures optimal operation in any demanding environment.

Top Brands and Models of Metering Pumps for Accuracy and Reliability

Metering pumps play a crucial role across various industries. Their accuracy ensures precise fluid control, which is vital for production quality. One report noted that improper fluid dosing can lead to a 15% decrease in product yield. Industries such as pharmaceuticals, chemicals, and food rely on metering pumps for consistent results.

Leading brands focus on reliability and performance. They often use advanced materials to enhance pump longevity. For instance, ceramic components can significantly reduce wear. However, these pumps must be regularly maintained. Neglecting maintenance can result in inaccuracies and increased operational costs. A study highlights that 30% of metering pump failures are due to poor maintenance practices.

User feedback shows a mix of satisfaction and frustration. Some users report excellent precision, while others encounter calibration issues. The need for better instructions is apparent. It's essential to continuously improve user experience while acknowledging the limitations of current technologies. The pursuit of accuracy in metering pumps remains an ongoing challenge.

Top 10 Metering Pumps for Accurate Fluid Control in Various Industries

| Pump Model | Flow Rate (L/h) | Pressure Rating (bar) | Accuracy (%) | Application Area |

|---|---|---|---|---|

| Model A | 1 - 10 | 10 | ±1% | Chemical Processing |

| Model B | 5 - 50 | 5 | ±0.5% | Water Treatment |

| Model C | 10 - 100 | 8 | ±2% | Food & Beverage |

| Model D | 2 - 20 | 15 | ±1.5% | Pharmaceuticals |

| Model E | 3 - 30 | 7 | ±1% | Agriculture |

| Model F | 4 - 40 | 20 | ±0.5% | Mining |

| Model G | 6 - 60 | 12 | ±1% | Oil & Gas |

| Model H | 1 - 15 | 18 | ±2% | Textiles |

| Model I | 8 - 80 | 9 | ±1.5% | HVAC |

| Model J | 9 - 90 | 6 | ±0.75% | Paper & Pulp |

Applications of Metering Pumps in Chemical, Water Treatment, and Food Industries

Metering pumps play a vital role across various industries. They ensure precise fluid control, which is critical in applications like chemical processing. In these settings, accurate dosing shapes the quality of products. A small mistake can lead to costly errors or unsafe conditions. It's important to evaluate how each pump manages flow rates under varying pressures.

In water treatment, metering pumps are essential for adding chemicals. They guarantee the right doses of disinfectants or coagulants. Ensuring compliance with health standards adds another layer of complexity. Operators must constantly monitor systems, as fluctuations in water supply can affect dosing accuracy. Adjustments may be needed often, even when conditions seem stable.

Food industries also rely on metering pumps for flavorings and preservatives. Consistency in taste and safety is paramount. Overshooting or undershooting doses can impact both. This process requires continuous checks and balances. Workers need training to handle equipment properly. Each application has unique challenges, highlighting the need for ongoing improvements in practices and technology.

Related Posts

-

7 Best Dosing Pumps for Precision Chemical Dispensing

-

How to Choose the Right Dosing Pump for Your Industrial Needs Based on Flow Rates and Chemical Compatibility

-

5 Best Chemical Pumps for Efficient Industrial Use

-

Top 10 Best High Pressure Chemical Pumps for Optimal Performance

-

7 Best Industrial Pumps You Should Consider for Your Next Project

-

How to Effectively Pump Water for Irrigation and Home Use