Blog

- Home

- Blog

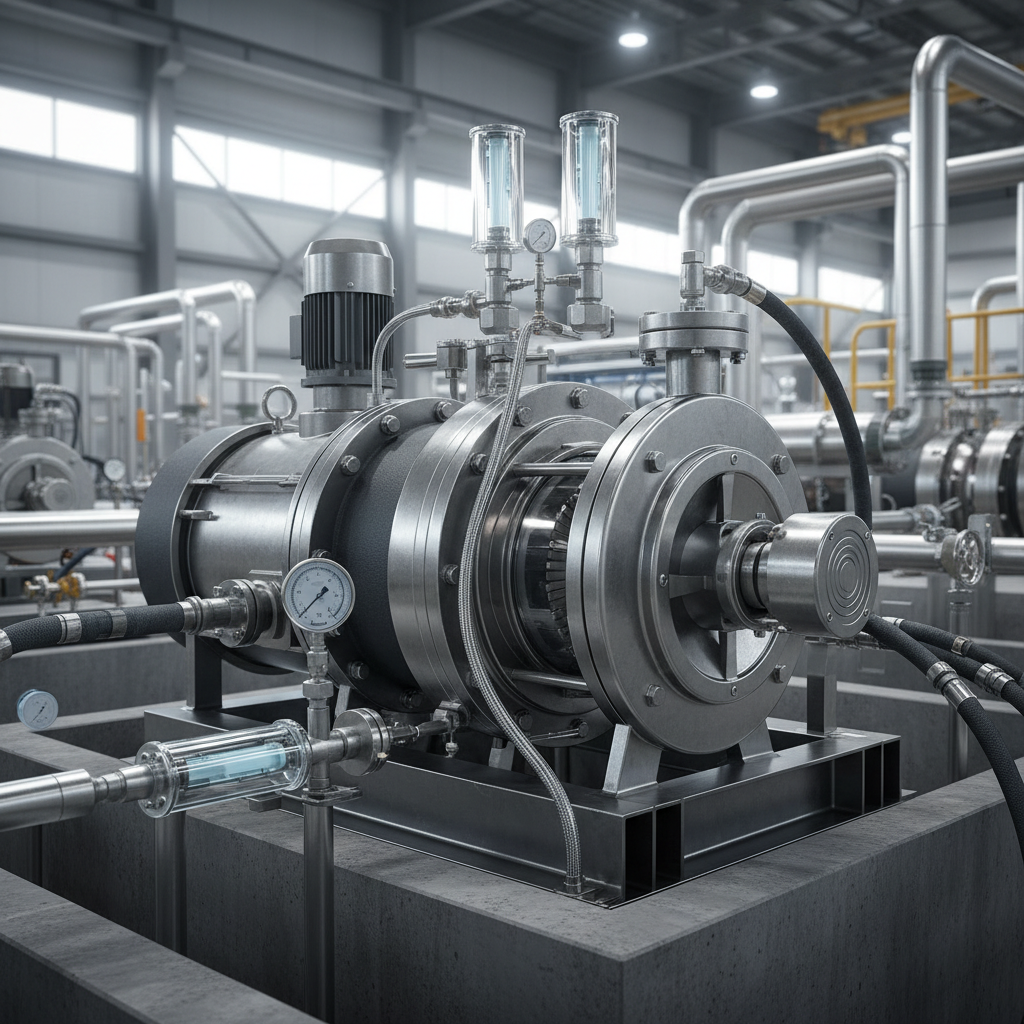

Top 10 Best High Pressure Chemical Pumps for Optimal Performance

In the ever-evolving landscape of industrial applications, the importance of utilizing reliable and efficient High Pressure Chemical Pumps cannot be overstated. According to a recent report by MarketsandMarkets, the global market for chemical pumps is projected to reach $5.29 billion by 2025, with high pressure applications spearheading this growth due to their critical role in fluid transfer across various sectors. The demand for robust and high-performing pumps is driven by the need for enhanced process efficiency, safety, and environmental compliance.

Industry expert Dr. John Smith, a leading authority on pumping technologies, emphasizes the significance of selecting the right equipment: "The efficiency and reliability of a High Pressure Chemical Pump can drastically impact a facility's operational performance and sustainability goals." His insights underscore the necessity for industries to invest in high-quality pumps that can handle aggressive chemicals under pressure while ensuring minimal downtime and maintenance costs.

This article presents the top 10 best High Pressure Chemical Pumps that not only exemplify optimal performance but also adhere to the stringent demands of modern industrial applications. Each selection is based on rigorous evaluation criteria, including pressure capabilities, material composition, and energy efficiency, aiming to guide professionals in making informed decisions for their operational needs.

Understanding the Key Features of High Pressure Chemical Pumps

High pressure chemical pumps are essential for a variety of industrial applications, where precise flow control and durability are crucial. When evaluating these pumps, there are several key features to consider. First and foremost is the pump material; selecting the right material, such as stainless steel or specialized alloys, ensures resistance to harsh chemicals and high temperatures. For example, according to a 2022 industry report by Frost & Sullivan, pumps constructed from high-grade materials can last up to 30% longer than standard models in corrosive environments.

Another critical feature is the pump's sealing technology. Advanced sealing mechanisms, such as mechanical seals or magnetic drive designs, minimize leakage and enhance operational efficiency. A study from the American Society of Mechanical Engineers (ASME) highlights that effective sealing can reduce maintenance costs by up to 20%. Additionally, the pump's flow rate and pressure capabilities must match the specific requirements of the application, ensuring optimal performance under varying conditions. Understanding these factors not only helps in choosing the right pump but also in maximizing the longevity and efficiency of the pumping system.

Top 10 Best High Pressure Chemical Pumps Performance Comparison

This chart illustrates the maximum pressure capability of the top 10 high-pressure chemical pumps. Each pump is evaluated based on its performance, measured in psi (pounds per square inch). The comparison highlights the varying performance levels across different models, providing insight into which pumps may be best suited for high-pressure applications in chemical handling.

Comparative Analysis of Top High Pressure Chemical Pump Brands

The global centrifugal pump market is projected to experience significant growth, with the market size valued at approximately $42.20 billion in 2024 and anticipated to reach $69.00 billion by 2032. This expansion highlights the increasing demand for high-pressure chemical pumps, which play a crucial role across various industrial applications, including processing and manufacturing in sectors such as petrochemicals, pharmaceuticals, and water treatment. The comparative analysis of leading high-pressure chemical pump brands reveals a diverse array of options designed to meet specific performance requirements, emphasizing efficiency, reliability, and operational cost-effectiveness.

As industries continue to innovate and evolve, the emphasis on advanced technologies in chemical pump design demonstrates the necessity for manufacturers to adapt to changing market dynamics. The growth of the pressure washer market, projected to expand from its current size, further underscores the importance of high-pressure pumping solutions. Companies that effectively leverage innovative capabilities and focus on delivering optimal performance are likely to lead in this competitive landscape, ensuring their products remain at the forefront of industry advancements.

Evaluating Performance Metrics in High Pressure Chemical Pumps

When evaluating performance metrics in high pressure chemical pumps, several key factors come into play. First, the pump's flow rate is a crucial metric that describes how much fluid can be moved in a given timeframe. A high flow rate is essential for operations requiring rapid chemical transfer. Additionally, pressure ratings must be considered, as pumps must withstand the specific demands of corrosive and abrasive chemicals without compromising integrity or safety.

Tips: Always check the manufacturer's specifications to ensure the pump's flow rate and pressure ratings align with your operational needs. Another important metric is the efficiency of the pump, which refers to how effectively it converts input energy into fluid movement. High efficiency leads to lower energy costs and reduced wear on components, ultimately extending the life of the pump.

Tips: Conduct regular maintenance checks to keep the pump operating at optimal efficiency and prevent unexpected downtimes. Lastly, material compatibility should not be overlooked; the choice of materials used in the pump construction can significantly affect performance when dealing with aggressive chemicals. By prioritizing these metrics, one can select a high pressure chemical pump that delivers optimal performance tailored to specific operational requirements.

Maintenance Tips for Ensuring Longevity of Chemical Pumps

Proper maintenance of high-pressure chemical pumps is crucial for ensuring their optimal performance and longevity. According to a report by the Hydraulic Institute, regular maintenance can extend the lifespan of pumps by up to 30%. This is particularly significant in industries dealing with corrosive or high-viscosity chemicals, where the failure of a pump can lead to costly downtimes and safety hazards. Basic maintenance practices include routine inspections, checking for leaks, and monitoring the condition of seals and bearings. Implementing a predictive maintenance program using condition monitoring technologies can further preempt failures, allowing for timely interventions before issues escalate.

Additionally, the American Chemical Society emphasizes the importance of proper chemical compatibility and pump selection to reduce wear and tear. Using pumps that are not suited for specific chemicals can lead to premature failure and increased maintenance costs. Thermal and hydraulic performance audits are also recommended every six months to optimize the operational efficiency of pumps. By adhering to these maintenance tips and utilizing relevant industry guidelines, companies can significantly improve the reliability and effectiveness of their chemical pumping systems, ultimately leading to enhanced productivity and reduced operational costs.

Cost-Benefit Considerations When Choosing High Pressure Chemical Pumps

When selecting high pressure chemical pumps, cost-benefit considerations are crucial for achieving optimal performance without overspending. A balance must be struck between the initial investment and the long-term operational costs. While cheaper pumps may appear attractive upfront, they often come with higher maintenance expenses or increased energy consumption over time. Therefore, evaluating the total cost of ownership, which includes installation, maintenance, and energy costs, is essential for making an informed decision.

Moreover, durability and efficiency should also influence the choice of pump. High-quality pumps may require a higher initial investment but can lead to significant savings due to reduced downtime and lower maintenance needs. It’s important to consider the specific application requirements, such as chemical compatibility and flow rate, to ensure that the chosen pump offers both reliability and efficiency. By taking these factors into account, businesses can ensure they invest in high pressure chemical pumps that not only meet their immediate needs but also contribute to overall operational efficiency and cost-effectiveness in the long run.

Related Posts

-

Understanding the Importance of Water Metering for Sustainable Water Management

-

The Science Behind Pump Water and Its Impact on Sustainable Agriculture

-

Understanding Diaphragm Pumps: Key Technologies and Their Impact on Fluid Transfer Efficiency

-

How to Choose the Right Plunger Pump for Your Industrial Needs

-

How to Choose the Right High Pressure Pump for Your Industrial Needs

-

How to Select the Right Chemical Metering Pump for Your Application