Blog

- Home

- Blog

Ultimate Guide to Selecting the Right Hydraulic Diaphragm Pump for Your Industrial Needs

In the ever-evolving industrial landscape, the Hydraulic Diaphragm Pump stands out as a vital component for efficient fluid management across various applications. According to a recent report by Research and Markets, the global diaphragm pump market is expected to grow at a CAGR of over 6% from 2021 to 2026, driven by increasing demand in sectors such as water treatment, chemicals, and pharmaceuticals. The versatility, safety, and ability to handle a wide range of fluids make hydraulic diaphragm pumps an ideal choice for industries requiring reliable performance under challenging conditions. As businesses seek to optimize their operations, understanding the different types of hydraulic diaphragm pumps and their specific functionalities becomes crucial. This guide aims to provide insights into selecting the right pump to meet your industrial needs effectively.

Understanding the Functionality and Advantages of Hydraulic Diaphragm Pumps in Industry

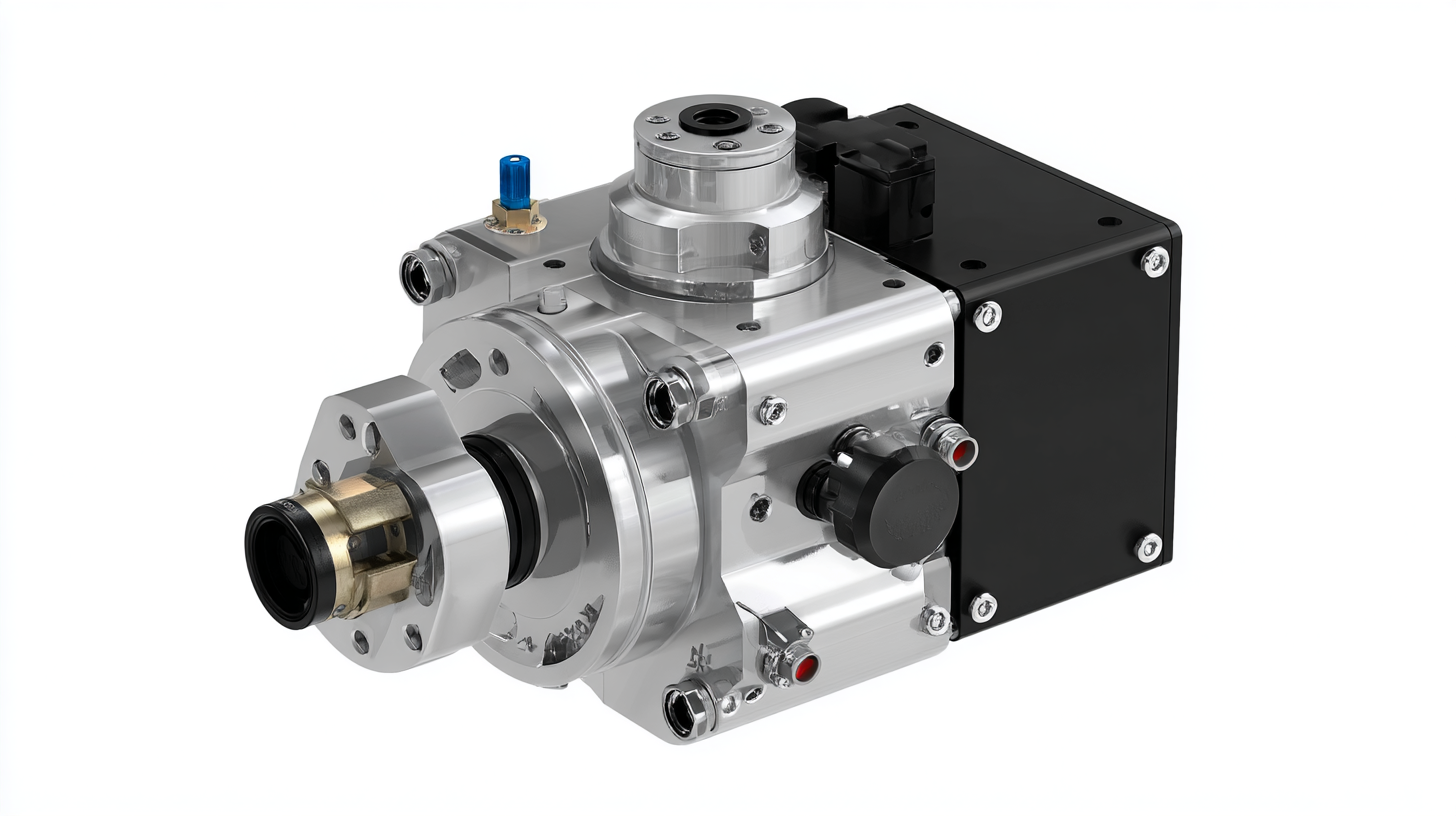

Hydraulic diaphragm pumps are essential tools in various industrial applications, particularly when precise fluid handling is required. The unique design of these pumps, which utilizes a diaphragm to create pressure differentials, enables them to move a wide range of fluids, including those that are viscous, abrasive, or contain solids. This functionality makes them particularly valuable in industries such as chemical processing, wastewater treatment, and food and beverage production.

One of the key advantages of hydraulic diaphragm pumps is their ability to maintain consistent flow rates while handling challenging materials. This reliability stems from their construction, which minimizes the risk of leaks and reduces the likelihood of contamination—an essential factor in industries where safety and quality control are paramount. Additionally, the flexibility offered by hydraulic diaphragm pumps allows for easy adjustment to various operating conditions, making them a versatile solution for meeting diverse industrial needs. Their low maintenance requirements also contribute to reduced downtime and operational costs, further enhancing their appeal for businesses seeking efficient and effective fluid management solutions.

Key Parameters to Consider When Choosing a Hydraulic Diaphragm Pump

When selecting a hydraulic diaphragm pump for industrial applications, several key parameters should be at the forefront of your decision-making process. First and foremost, understand the flow rate requirements of your operation. This measurement, typically expressed in gallons per minute (GPM) or liters per minute (LPM), is crucial as it directly impacts the efficiency of your system. Assessing the viscosity of the fluid being pumped is equally essential; thicker fluids may require a pump with specific features to ensure optimal performance without sacrificing reliability.

In addition to flow rate and viscosity, consider the materials of construction and compatibility with the pumped medium. For harsh chemicals or abrasive materials, selecting a pump made from durable, corrosion-resistant materials can prevent premature failure and costly downtimes. Furthermore, evaluate the pump's pressure rating and pulsation levels, as these factors affect not only the system's overall stability but also the longevity of other connected components. By carefully examining these parameters, you can make an informed choice that enhances your operational effectiveness.

Comparing Different Types of Hydraulic Diaphragm Pumps for Industrial Applications

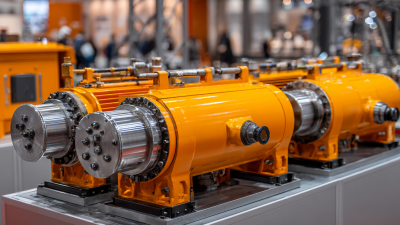

When selecting a hydraulic diaphragm pump for industrial applications, it's crucial to compare the different types available to ensure optimal performance for your specific needs. The most common types include AODD pumps, electric diaphragm pumps, and hydraulic diaphragm pumps. Each type has its unique advantages—AODD pumps, for example, excel in handling abrasive fluids and can run dry without damage, making them ideal for various processing environments. They are also portable and versatile, which can be beneficial for plants requiring mobility between different tasks.

On the other hand, electric diaphragm pumps offer a compact design and are often more energy-efficient, suitable for applications where power supply stability is a concern. Their ability to provide precise flow rates makes them a favorite for chemical processing industries. Hydraulic diaphragm pumps, while being more robust, are typically used in demanding applications requiring high pressure and flow rates, making them essential for heavy-duty operations. By evaluating the specific operational requirements and the advantages of each pump type, you can make an informed decision that ensures reliability and efficiency in your industrial processes.

Common Applications and Industries Utilizing Hydraulic Diaphragm Pumps

Hydraulic diaphragm pumps are essential tools used across various industries due to their superior performance in handling abrasive and corrosive fluids. Common applications include wastewater treatment, chemical processing, and food and beverage manufacturing. In wastewater treatment facilities, these pumps efficiently manage sludge and other viscous materials, ensuring smooth operations and compliance with environmental regulations. Similarly, in the chemical industry, their ability to handle hazardous substances without leaks or contamination is crucial for safety and quality control.

Tips for selecting the right hydraulic diaphragm pump include evaluating the fluid characteristics you'll be pumping. Consider factors such as viscosity, temperature, and the potential for solids. Additionally, assess the required flow rate and pressure for your specific application. It's also essential to think about the maintenance and serviceability of the pump, as simpler designs can often lead to reduced downtime and lower operational costs.

In the food and beverage sector, hydraulic diaphragm pumps help maintain product integrity by preventing any contamination during the transfer process. When choosing a pump for this industry, prioritize options that meet sanitation standards and consider the ease of cleaning. Understanding the unique needs and challenges of your industry will guide you in selecting the most efficient and reliable pump for your specific requirements.

Evaluating Performance Metrics: Flow Rate, Pressure, and Efficiency in Hydraulic Diaphragm Pumps

When selecting the right hydraulic diaphragm pump for industrial applications, it's crucial to evaluate key performance metrics such as

flow rate, pressure, and

efficiency. The flow rate determines how much fluid the pump can deliver over

a specific period, making it vital for meeting operational demands. It's essential to assess your process requirements carefully to

select a pump with an optimal flow rate that can handle your workload without unnecessary strain.

Pressure is another critical factor that influences pump performance. Understanding the required pressure for your application can

help you select a diaphragm pump that not only meets these specifications but also operates reliably under varying conditions.

High pressure may be required for certain processes, so ensure the pump materials and design are suited to withstand these levels

without compromising safety or function.

Tips:

- Consider using flow meters to monitor the efficiency of your pump in real-time, enabling better adjustments and improvements over time.

- Regularly inspect and maintain your diaphragm pump to avoid efficiency losses; worn-out components can significantly impact flow rate and pressure delivery.

- Always consult with manufacturers or industry experts to find pumps specifically tailored to your needs, as they can often provide insights into the best practices and suitable models.

Related Posts

-

How to Select the Right Hydraulic Diaphragm Pump for Your Industrial Needs

-

Unlocking Efficiency: The Significant Advantages of Plunger Metering Pumps in Process Industries

-

5 Best Tips for Choosing the Right Hydraulic Pump for Your Needs

-

Understanding Common Issues Faced by Users of Plunger Pumps

-

10 Tips for Maximizing Efficiency with High Pressure Hydraulic Pumps in Industrial Settings

-

How to Optimize Your Hydraulic Pump System for Maximum Efficiency