Blog

- Home

- Blog

How to Select the Best Piston Pump for Your Industrial Needs

In the realm of industrial applications, the selection of the right equipment is crucial for optimizing performance and efficiency, particularly when it comes to fluid handling systems. Among the various technologies available, piston pumps stand out for their ability to handle high pressures and aggressive fluids. According to a report by Research and Markets, the global piston pump market is projected to reach $4.77 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.6%. This growth is driven by increasing demand across various sectors, such as oil and gas, chemical processing, and water treatment. Understanding the various types of piston pumps and their specific features is essential for industrial professionals looking to make informed decisions that align with their operational needs. In this blog, we will delve into the types of piston pumps available and the key factors to consider when selecting the best option for your industrial requirements.

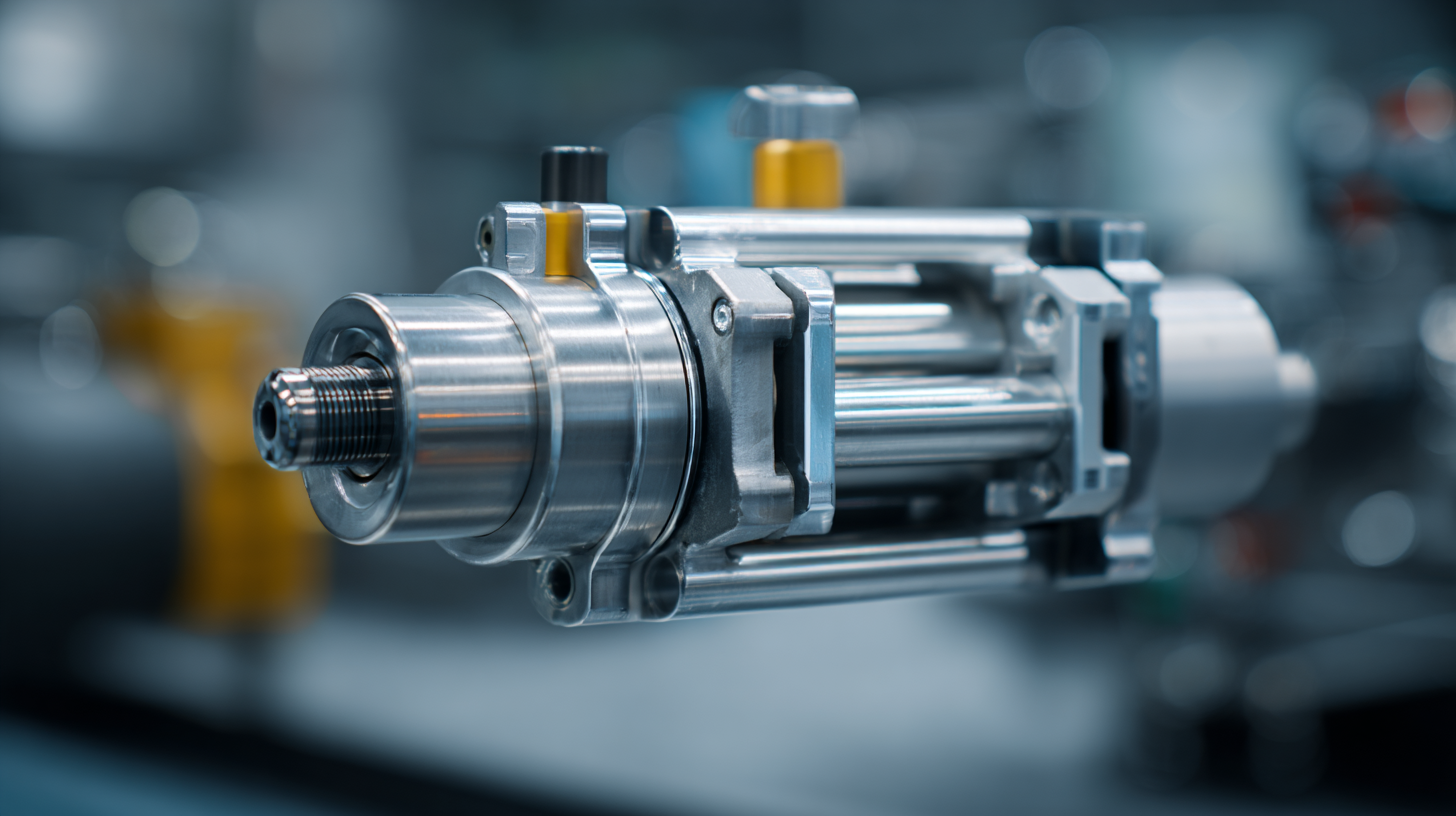

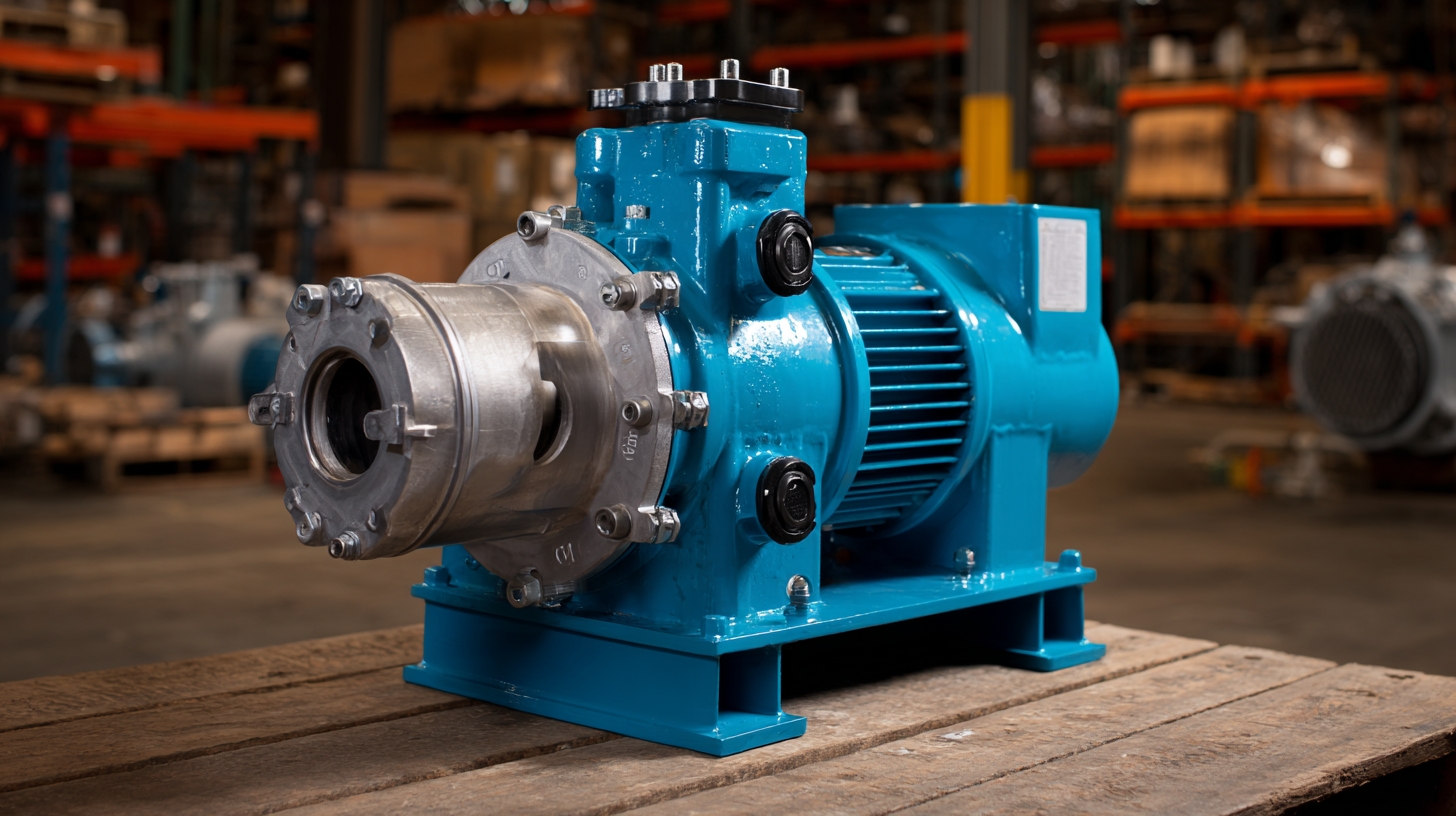

Types of Piston Pumps and Their Industrial Applications

Piston pumps are vital components in various industrial applications, known for their reliability and efficiency in transferring fluids. There are several types of piston pumps, each designed to meet specific operational needs. The most common types include single-acting and double-acting piston pumps. Single-acting pumps operate by utilizing the pressure on one side of the piston during the stroke cycle, making them ideal for low-pressure applications like water supply systems. In contrast, double-acting pumps leverage pressure on both sides, enabling them to handle higher pressure environments, making them suitable for applications in construction and hydraulic systems.

Another important classification is based on the piston design, which includes diaphragm and plunger piston pumps. Diaphragm piston pumps are excellent for handling corrosive or viscous fluids, as they prevent contamination from the pumped medium and reduce wear and tear on the components. Conversely, plunger piston pumps are preferable for their ability to provide high flow rates and are commonly found in oil and gas industries where fluid dynamics demand rigorous performance. Understanding the distinct types and their advantages is crucial for selecting the right piston pump to optimize industrial operations effectively.

Key Factors to Consider When Choosing a Piston Pump

When selecting the best piston pump for your industrial needs, several key factors must be considered to ensure optimal performance and efficiency. One important aspect is the operating environment and the specific application of the pump. For instance, understanding the influence of working condition variations on lubrication characteristics can significantly impact the longevity and reliability of the pump. This insight is crucial when selecting piston pumps for applications with varying loads and pressures.

Another factor to consider is the volumetric efficiency of the piston pump, particularly under high-pressure conditions. Recent studies indicate that increasing rotational speed can enhance volumetric efficiency while minimizing the adverse effects of leakage and reverse flow. Additionally, evaluating the design features, such as variable displacement capabilities or precision dispensing for specific fluid types, can provide significant advantages according to the application requirements. By carefully analyzing these factors, you can choose a piston pump that not only meets your technical specifications but also enhances operational efficiency in your industrial applications.

Comparative Analysis of Different Piston Pump Designs

When selecting the best piston pump for industrial needs, it’s essential to conduct a comparative analysis of different designs. A thorough understanding of various piston pump configurations can lead to better efficiency and reliability in application. Recent studies highlight advancements in axial piston pump designs, particularly focusing on the cylinder block/valve plate interface. This interface plays a crucial role in optimizing performance, with models and experimental data suggesting that refining this element can significantly enhance operational efficiency and reduce wear.

Tip: Consider the capped piston design when evaluating high-speed and high-pressure axial piston pumps. This design not only minimizes compressibility effects and pressure ripple but also helps mitigate cavitation, a common issue in fast-moving pumps.

Furthermore, investigating the influence of hydraulic circuit setup on pump performance is critical. By employing both numerical simulations and experimental analysis, one can gain insights into how different configurations affect noise, vibration, and harshness (NVH) behaviors, ultimately leading to improved pump design and selection strategies.

Maintenance Tips for Optimal Piston Pump Performance

When it comes to the efficiency of piston pumps in industrial applications, regular maintenance is crucial for optimal performance. According to a report by the Hydraulic Institute, approximately 70% of all pump failures can be attributed to inadequate maintenance practices. This statistic highlights the importance of adhering to a structured maintenance schedule to prevent downtime and extend the life of your equipment. Regularly inspecting components such as seals and pistons can significantly improve operational reliability and efficiency.

Another key aspect of maintaining piston pumps is to ensure proper lubrication. The American Society of Mechanical Engineers recommends monitoring lubricant condition and levels as part of routine maintenance. For instance, utilizing high-quality synthetic oils can reduce friction and wear, potentially increasing pump life by up to 30%. Additionally, operators should conduct routine checks for signs of wear and tear, which can be done through vibration analysis and thermal imaging techniques. Implementing these strategies not only enhances pump performance but also translates to considerable cost savings in the long run.

Cost-Effectiveness of Various Piston Pump Types in Industry

When selecting a piston pump for industrial applications, cost-effectiveness plays a crucial role in decision-making. Different types of piston pumps—such as single-acting, double-acting, and hydro-pneumatic—offer varying levels of efficiency and operational cost that can significantly impact overall project budgets. For instance, while single-acting pumps tend to be more economical upfront, they may require more frequent maintenance or replacement, which can add to long-term expenses. On the other hand, double-acting pumps, although initially pricier, provide higher efficiency and reliability, potentially leading to lower operational costs over time.

Another factor to consider is the specific application and fluid being pumped. Certain materials may cause wear and tear on the pump components, influencing the total cost of operation. Selecting a pump that is compatible with the operational environment can save costs related to repairs and replacements. Additionally, investing in pumps with advanced technology such as variable speed drives can enhance energy efficiency, further optimizing cost-effectiveness. By understanding the trade-offs between different piston pump types and their long-term costs, businesses can make informed decisions that align with their industrial needs and budget constraints.

Cost-Effectiveness Comparison of Various Piston Pump Types

This chart illustrates the cost-effectiveness of different types of piston pumps used in industrial applications. The costs are represented in USD, and the efficiency is measured in output per hour. This comparison helps in selecting the most suitable piston pump based on budget and productivity requirements.

Related Posts

-

10 Tips for Maximizing Efficiency with High Pressure Hydraulic Pumps in Industrial Settings

-

5 Innovative Ways Pressure Pumps Enhance Industrial Efficiency

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications

-

Understanding Common Issues Faced by Users of Plunger Pumps

-

Top Strategies for Sourcing High Performance Industrial Pumps Globally

-

5 Best Tips for Choosing the Right Hydraulic Pump for Your Needs