Blog

- Home

- Blog

How to Select and Maintain a Plunger Metering Pump for Optimal Performance

In the world of industrial fluid handling, selecting and maintaining a Plunger Metering Pump is crucial for ensuring optimal performance and efficiency. According to a report by the Fluid Control Association, improper pump selection and maintenance can lead to a significant increase in operational costs, potentially exceeding 20% of a facility's total expenses. As the demand for precision and reliability in fluid delivery systems continues to rise, understanding the operational intricacies of Plunger Metering Pumps has become more essential than ever.

Industry expert Dr. Sarah Thorne, a leading authority in pump technology, emphasizes the importance of diligent maintenance practices, stating, "Regular inspection and proper selection of Plunger Metering Pumps can dramatically enhance system efficiency and lifespan." This statement reflects a broader consensus among professionals in the field regarding the clear relationship between maintenance practices and operational reliability. By implementing a structured approach to pump selection and maintenance, businesses can harness the full potential of Plunger Metering Pumps, ensuring they meet both their current and future fluid management needs.

Understanding Plunger Metering Pumps: Principles and Functionality

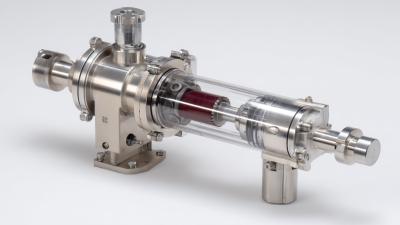

Plunger metering pumps are essential components in various industrial applications, providing precise liquid flow control. These pumps operate on a simple yet effective principle: the movement of a plunger within a cylinder generates pressure, allowing for the accurate dosing of fluids. The displacement of the plunger directly correlates with the volume of liquid delivered, making these pumps extremely reliable for applications requiring consistent flow rates.

Tips for optimal performance include regularly checking for wear on the plunger and cylinder, as abrasion can lead to leaks and reduced efficiency. Additionally, ensuring that the suction and discharge valves function correctly is vital; any blockage or damage can significantly affect performance. Maintaining proper lubrication within the pump mechanism will also help in minimizing friction, further enhancing the longevity and reliability of the system.

Understanding the mechanics of plunger metering pumps allows operators to optimize their performance. Regular maintenance schedules, including inspection of seals and gaskets, ensure that the pump continues to operate smoothly. Incorporating a filtration system can prevent contaminants from entering the pump, preserving its integrity. Ultimately, attention to these details ensures that plunger metering pumps deliver precise and reliable results throughout their operational lifespan.

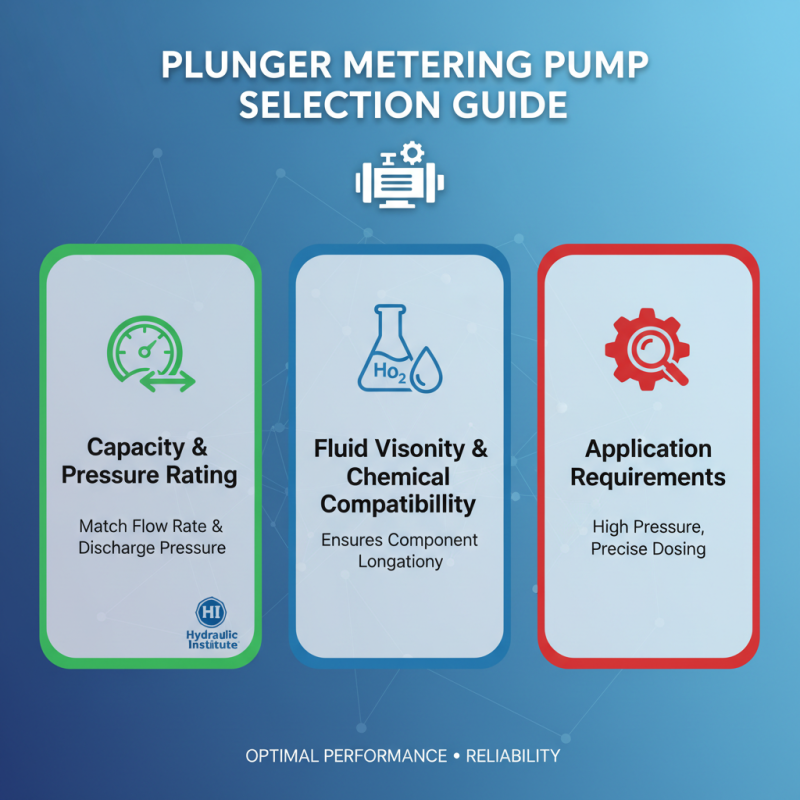

Criteria for Selecting the Right Plunger Metering Pump for Your Needs

When selecting a plunger metering pump, several key criteria must be considered to ensure optimal performance in your specific application. One of the primary factors is the pump's capacity and pressure rating. According to the Hydraulic Institute, a trusted resource in fluid handling, it is crucial to match the pump's flow rate and discharge pressure to the requirements of your system to achieve efficient operation. Typically, plunger pumps can handle high pressures, making them suitable for applications requiring precise dosing under challenging conditions. Understanding the viscosity and chemical compatibility of the fluid being pumped is also vital, as it affects the wear and longevity of pump components.

Another essential criterion is the construction materials of the pump. The American Society of Mechanical Engineers (ASME) emphasizes that using the right materials can significantly impact the durability and performance of the pump in harsh environments. For instance, pumps made with corrosion-resistant materials are better suited for handling aggressive chemicals, whereas those with standard steel components may be more appropriate for simpler applications. It is also important to look for additional features such as adjustable stroke length and frequency, which can enhance controllability and flexibility in diverse operations. Ensuring that these criteria are met will facilitate smoother performance and prolong the life of the metering pump in your application.

Installation Best Practices for Plunger Metering Pumps

When installing a plunger metering pump, it is crucial to follow specific best practices to ensure optimal performance and longevity. First, select a suitable installation location that is clean, dry, and easily accessible for maintenance. Adequate spacing around the pump facilitates airflow and minimizes heat buildup, which can adversely affect performance. Careful attention should also be paid to the alignment and leveling of the pump; improper alignment can lead to excessive wear and tear on the components, potentially leading to premature failure.

Additionally, ensuring proper piping configuration is vital during installation. Use the appropriate pipe sizes according to the manufacturer's specifications, as oversizing or undersizing can impact flow rates and pressures. Incorporating valves, fittings, and filters can help maintain consistent operation while protecting the pump from contaminants. During the initial setup, it is also recommended to follow the priming procedure diligently and check for leaks before starting the pump. Regular monitoring of pressure and flow during operation can help identify any discrepancies early, allowing for timely adjustments and interventions. Following these best practices will significantly enhance the efficiency and reliability of plunger metering pumps over their operational lifespan.

How to Select and Maintain a Plunger Metering Pump for Optimal Performance - Installation Best Practices for Plunger Metering Pumps

| Parameter | Optimal Value | Importance | Maintenance Frequency |

|---|---|---|---|

| Flow Rate | 0.1 - 100 GPH | Critical for accuracy | Monthly |

| Discharge Pressure | Up to 4000 PSI | Ensures proper function | Quarterly |

| Fluid Temperature | -10 to +200 °F | Affects viscosity | Biannually |

| Seal Condition | No leaks | Prevent downtime | Monthly |

| Pump Mounting Level | Stable and level | Ensures operation efficiency | At installation and annually |

Routine Maintenance Procedures for Plunger Metering Pumps

Routine maintenance of plunger metering pumps is crucial to ensuring their optimal performance and longevity. According to a study by the International Society for Automation, proper maintenance can reduce operational costs by up to 20% and significantly lower the risk of unexpected downtimes. Regularly scheduled checks should focus on visual inspections for leaks, wear, and alignment issues, as these are often the first indicators of potential problems. Operators should also monitor the pump's pressure and flow rates closely, comparing them against manufacturers' specifications to identify any discrepancies early on.

In addition to visual inspections, lubrication and seal maintenance are critical. The Journal of Pump Engineering recommends changing lubricants every 500 operating hours or as advised by the pump's operational manual. This practice is essential to reducing friction and preventing mechanical failure. Furthermore, seals should be replaced periodically to avoid leaks that can lead to improper dosing or environmental concerns. By adhering to these routine maintenance procedures, operators can ensure their plunger metering pumps operate efficiently, providing precise fluid handling while minimizing disruptions in production processes.

Plunger Metering Pump Routine Maintenance Frequency

This chart displays the recommended frequency of routine maintenance procedures for plunger metering pumps to ensure optimal performance. Regular maintenance is crucial to prevent failures and enhance operational efficiency.

Troubleshooting Common Issues in Plunger Metering Pump Performance

Plunger metering pumps are essential in many industrial applications, but they can face various performance issues over time. Common problems include fluctuations in flow rate, excessive wear on plunger seals, and unexpected pressure drops. According to a 2022 industry report by the Fluid Power Association, approximately 20% of operational downtime in pumping systems is attributed to inadequate maintenance and troubleshooting. Therefore, a robust maintenance plan and awareness of potential issues are crucial for ensuring optimal performance and minimizing disruption.

When troubleshooting a plunger metering pump, it is important to systematically examine the system's components. For instance, if a pump exhibits inconsistent flow rates, operators should first check the suction conditions, as blockages or air leaks in the suction line can lead to air entrainment, affecting the performance. Furthermore, regular inspection of the plungers and seals is vital; wear and tear on these components can drastically impact the integrity of the pump, leading to leakage and inefficient operation. The Hydraulic Institute suggests that addressing minor discrepancies early can extend a pump's service life by 30-50%, emphasizing the importance of proactive maintenance strategies in sustaining performance.

Related Posts

-

Exploring the Impact of Diaphragm Metering Pumps at the 138th China Import and Export Fair 2025

-

Understanding the Efficiency and Applications of Plunger Metering Pumps in Industrial Settings

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications

-

What Makes Plunger Metering Pump Essential for Precision Fluid Control

-

Understanding Common Issues Faced by Users of Plunger Pumps

-

How to Select the Right Chemical Metering Pump for Your Application