Blog

- Home

- Blog

How to Optimize Your Hydraulic Pump System for Maximum Efficiency

In today's industrial landscape, optimizing hydraulic pump systems has become crucial for enhancing operational efficiency and reducing costs. According to a recent report by the Hydraulic Institute, well-maintained pump hydraulic systems can achieve energy savings of up to 30% compared to inefficient systems. Additionally, a study from the International Energy Agency highlights that hydraulic systems account for approximately 30% of total energy consumption in industrial applications.

The significance of maximizing efficiency in these systems cannot be overstated, as even minor improvements can lead to substantial cost reductions and increased productivity. In this guide, we will explore actionable strategies to optimize your hydraulic pump system, ensuring that you harness the full potential of your equipment while contributing to a more sustainable energy future.

Benefits of Regular Maintenance for Hydraulic Pump Systems

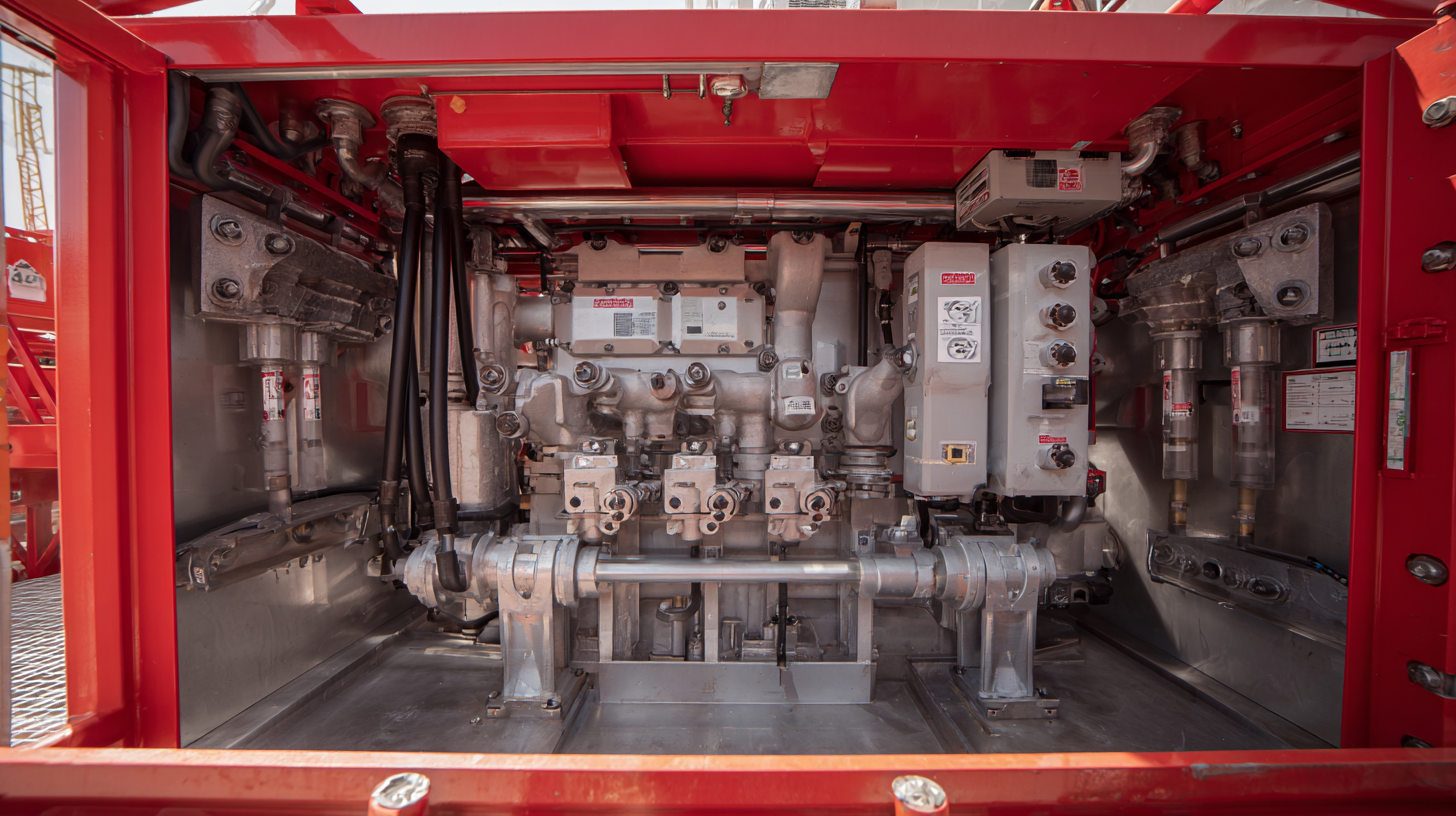

Regular maintenance is crucial for the efficiency and longevity of hydraulic pump systems. Over time, wear and tear can lead to reduced performance, increased energy consumption, and even catastrophic failures. By implementing a routine maintenance schedule, operators can identify potential issues early, ensuring that the system operates at peak efficiency. Regular checks on fluid levels, filter conditions, and hose integrity will help prevent costly downtime and repairs, ultimately enhancing overall productivity.

Another important aspect of maintenance is the monitoring of system temperatures and pressures. These parameters can reveal insights into the health of the hydraulic system. Elevated temperatures, for instance, can indicate fluid degradation or excessive load, while unusual pressure fluctuations may point to leaks or blockages. Addressing these signs promptly not only extends the life of the hydraulic pump but also contributes to a safer work environment by minimizing the risk of system failures. By prioritizing maintenance, businesses can enjoy significant cost savings and improved operational reliability.

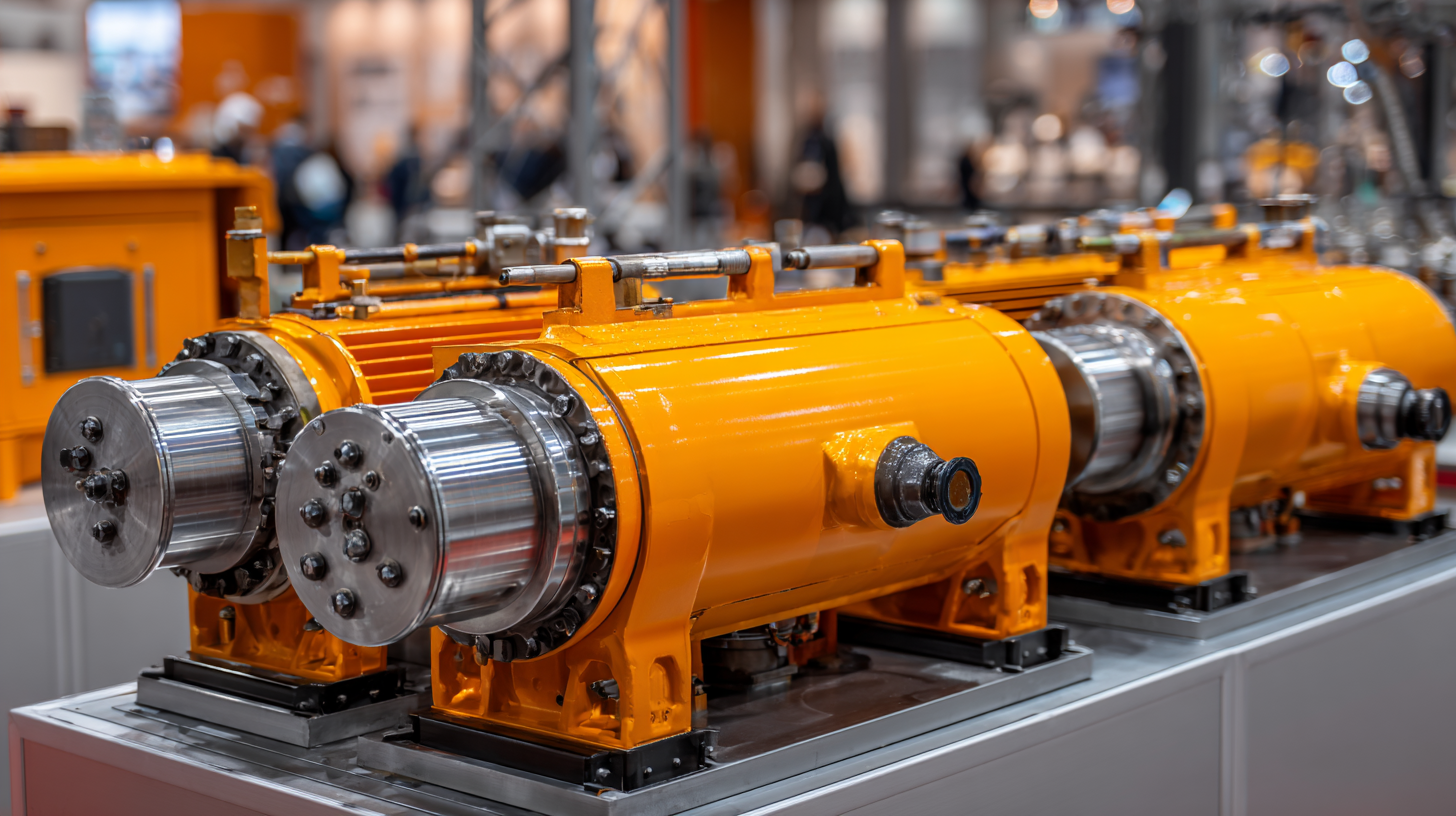

Essential Components for Optimizing Hydraulic Pump Performance

Optimizing the hydraulic pump system involves focusing on its essential components, which play a critical role in enhancing performance and efficiency. Key components include the hydraulic pump, reservoir, valves, and filters. According to a report from the National Fluid Power Association, implementing a regular maintenance schedule for these components can improve efficiency by as much as 30%. Proper selection of hydraulic fluid is also crucial; using fluids with lower viscosity can reduce friction losses, which are estimated to consume about 10-15% of the total energy in hydraulic systems.

Additionally, the configuration of hydraulic lines and the use of appropriate fittings can significantly influence the overall system efficiency. Research published in the Journal of Hydraulic Engineering highlights that reducing the length and number of bends in hydraulic lines can decrease pressure drops by nearly 20%. Moreover, integrating advanced components like variable displacement pumps allows for more precise control of hydraulic flow and pressure, thereby optimizing energy usage. By focusing on these essential elements, operators can ensure their hydraulic systems run at peak performance while minimizing energy consumption and operational costs.

Top 5 Techniques to Improve Energy Efficiency in Hydraulic Pumps

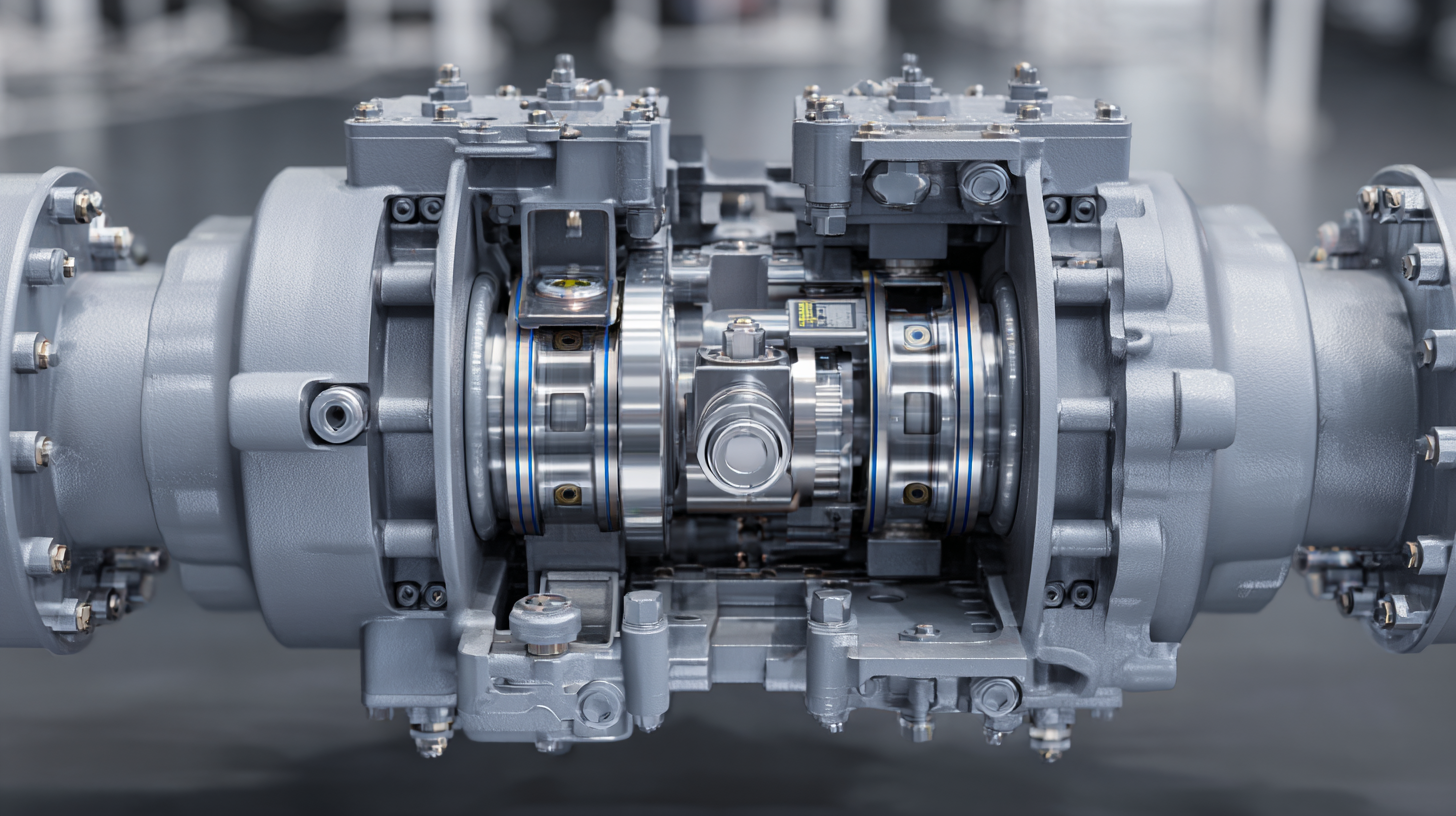

Optimizing the efficiency of hydraulic pump systems is crucial for enhancing overall performance and reducing operational costs. One of the top techniques involves regular maintenance, which ensures that all components function correctly and prevents energy loss due to wear and tear. Scheduled inspections and timely replacements of seals, filters, and fluid can significantly improve the system's performance and longevity.

Another effective method to boost energy efficiency is to properly size the hydraulic pump. An appropriately selected pump minimizes energy waste by matching the system's flow rate and pressure requirements. Additionally, utilizing variable-speed drives allows for better control over pump operation, enabling adjustments based on real-time demands. This adaptability can lead to considerable energy savings while maintaining optimal performance.

Lastly, consider integrating advanced system monitoring solutions. Employing sensors and data analytics can help identify inefficiencies, monitor performance metrics, and facilitate predictive maintenance. By implementing these strategies, you not only enhance the efficiency of your hydraulic pump system but also contribute to sustainable operational practices, ultimately leading to lower energy consumption and cost savings.

How to Select the Right Hydraulic Fluid for Maximum Efficiency

Selecting the right hydraulic fluid is crucial for optimizing the efficiency of hydraulic pump systems. According to a recent industry report, the choice of hydraulic fluid can impact system performance by up to 15%. This is primarily due to differences in viscosity, lubricity, and thermal stability. For instance, a fluid with a higher viscosity index can improve the operational range of the hydraulic system, maintaining performance in varying temperatures. It is recommended to select fluids formulated to meet the specific requirements of the system and operational conditions, thus enhancing efficiency and extending equipment lifespan.

Additionally, it is important to consider the environmental impact of hydraulic fluids. As stricter regulations are being enforced, choosing environmentally friendly options can reduce legal liabilities and improve sustainability credentials. Bio-based hydraulic fluids, for example, can provide similar performance levels compared to conventional fluids but with significantly lower ecological footprints. Studies indicate that transitioning to such fluids can reduce overall operational costs by up to 10% over time, making them a smart choice for companies looking to boost both efficiency and sustainability in their hydraulic operations.

How to Optimize Your Hydraulic Pump System for Maximum Efficiency

| Hydraulic Fluid Type | Viscosity (cSt at 40°C) | Temperature Range (°C) | Lubrication Properties | Cost ($/L) |

|---|---|---|---|---|

| Mineral Oil | 32 | -20 to 50 | Good | 2.5 |

| Biodegradable Fluid | 46 | -15 to 45 | Excellent | 5.0 |

| Water-based Fluid | 10 | 0 to 60 | Moderate | 1.8 |

| Synthetic Fluid | 26 | -40 to 70 | Superior | 8.0 |

Innovative Technologies for Monitoring Hydraulic System Performance

In today's fast-paced industrial environment, optimizing hydraulic systems for maximum performance is crucial. Innovative technologies have emerged that provide real-time monitoring of hydraulic system performance, significantly enhancing efficiency and reducing operational costs. According to a report by the Hydraulic Institute, properly monitored hydraulic systems can improve energy efficiency by up to 30%. This statistic highlights the importance of investing in advanced monitoring solutions.

One cutting-edge approach involves the use of IoT sensors, which gather data on flow rates, pressure, and temperature. These sensors feed into centralized analytics platforms that utilize machine learning algorithms to predict performance trends and provide actionable insights. In fact, a study by McKinsey & Company indicated that predictive maintenance can reduce downtime by up to 50%. This shift towards data-driven decision making not only minimizes unexpected failures but also extends the life of hydraulic components.

Furthermore, the integration of cloud computing with hydraulic systems allows for easier data access and analysis from any location. This advancement empowers engineers to make informed adjustments in real-time, ensuring optimal performance. By embracing these innovative technologies, organizations can enhance their hydraulic pump systems, leading to significant gains in both efficiency and cost-effectiveness.

Related Posts

-

5 Best Tips for Choosing the Right Hydraulic Pump for Your Needs

-

5 Essential Tips for Maximizing Performance of High Pressure Hydraulic Pumps

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications

-

How to Select the Right Hydraulic Diaphragm Pump for Your Industrial Needs

-

7 Best Dosing Pumps for Precision Chemical Dispensing

-

5 Essential Tips for Sourcing the Best Pump Water Solutions Globally