Blog

- Home

- Blog

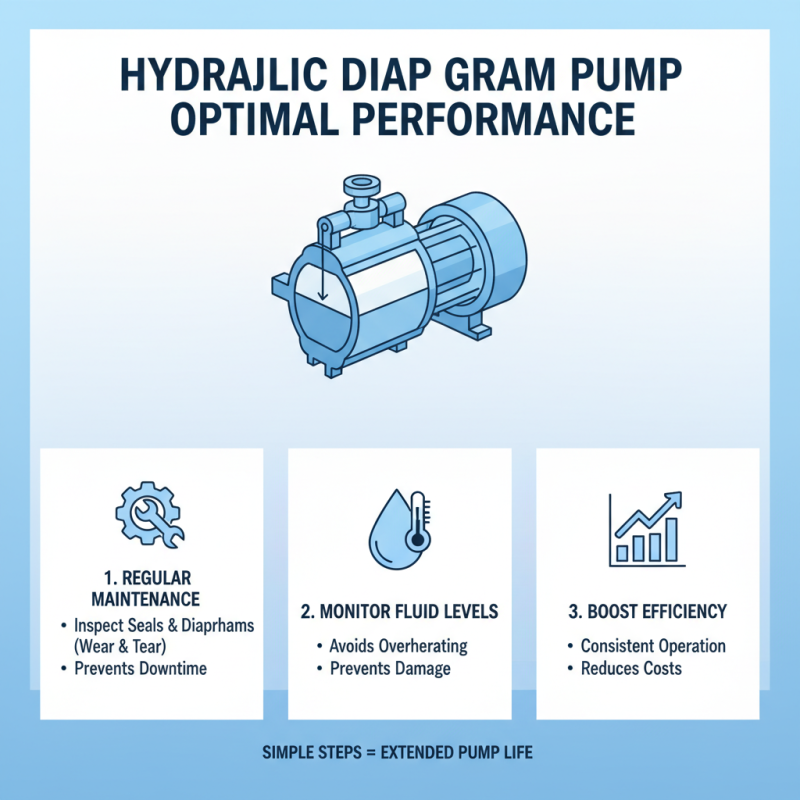

Hydraulic Diaphragm Pump Essential Tips for Optimal Performance

In the world of fluid management, the Hydraulic Diaphragm Pump stands out. This type of pump is highly regarded for its precision and flexibility. Many industries rely on these pumps for various applications. However, achieving optimal performance requires careful attention to detail.

Operating a Hydraulic Diaphragm Pump is not as straightforward as it may seem. Common issues arise during maintenance or installation. Users may overlook certain parameters, such as pressure settings or diaphragm wear. These mistakes can lead to performance dips.

Understanding the inner workings of a Hydraulic Diaphragm Pump is crucial. Regular checks on components can prevent avoidable breakdowns. Users should track performance metrics closely. A little effort can yield significant improvements in efficiency and longevity. Embrace the journey of learning, even when it feels challenging.

Understanding the Basics of Hydraulic Diaphragm Pumps

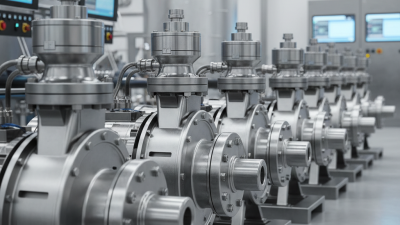

Hydraulic diaphragm pumps are versatile tools in fluid handling. They operate by using a flexible diaphragm to create a pumping action. This design helps avoid contamination, making them suitable for various applications.

Understanding the basics of these pumps is crucial for optimal performance. They can handle thick fluids and slurries, but care must be taken with viscosity. Running a pump outside its recommended range can lead to inefficiencies and accelerated wear. Monitoring the diaphragm's condition is important, as any signs of wear can impact performance.

Regular maintenance is key to longevity. Replace diaphragms periodically, and check seals for leaks. Ignoring these simple steps can result in costly downtimes and repairs. Pump operators should routinely assess system pressures and flow rates. It's vital to ensure that all components are functioning properly to avoid surprises. Reflection on these practices can lead to improved performance and reliability in the long run.

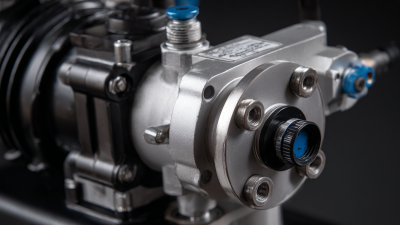

Key Components and Their Functions in Hydraulic Diaphragm Pumps

Hydraulic diaphragm pumps play a crucial role in various industrial applications. Understanding their key components helps in achieving optimal performance. The diaphragm is perhaps the most vital part. It separates the pump's working fluid from the hydraulic fluid. A well-maintained diaphragm can enhance the pump’s efficiency significantly. According to industry reports, a worn-out diaphragm can lead to a 20% drop in pumping efficiency.

Another important component is the hydraulic chamber. This chamber houses the diaphragm and provides a path for fluid movement. If the hydraulic chamber is not clean, it can cause cavitation. This could damage the diaphragm and negatively impact the pump's lifespan. Studies show that over 30% of pump failures are linked to issues within the hydraulic chamber.

Valves also play a critical role in this pump's operation. They control the flow and ensure that the fluid moves in the right direction. Improper valve adjustment can lead to backflow, which diminishes performance. Regular inspections are necessary, yet many operators overlook this aspect. Ignoring valve maintenance can lead to a complete system shutdown, which is costly in both time and resources.

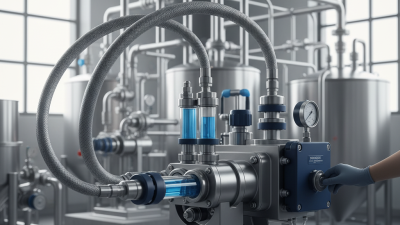

Maintenance Practices for Enhanced Performance

Proper maintenance of hydraulic diaphragm pumps is crucial for optimal performance. Regular checks can prevent costly downtimes. Keep an eye on the pump's seals and gaskets. Wear and tear can significantly affect efficiency.

Tips: Inspect these components regularly. A small crack could lead to leaks, impacting pressure. Clean the diaphragm periodically. Extreme conditions can cause damage.

Pay attention to the fluid being pumped. Use the right fluids to avoid pump wear. Different materials react differently. Misconfigurations can lead to inefficiencies.

Tips: Always refer to guidelines for compatibility. It’s important to listen for unusual noises during operation. This may indicate mechanical issues needing urgent attention. Analyze performance trends and prepare for maintenance before problems escalate.

Common Issues and Troubleshooting Techniques

Hydraulic diaphragm pumps are efficient, yet they can face common issues. Understanding these challenges is key to maintaining optimal performance. A report from the Hydraulic Institute states that improper maintenance can reduce pump efficiency by up to 30%. Regular checks can prevent this.

One frequent issue is diaphragm wear. This can lead to leaks or decreased flow rates. Check for signs of wear regularly. It's crucial to replace the diaphragm once you notice reduced performance. Tips: Monitor your pump’s sound. Strange noises may indicate internal issues.

Another common problem is cavitation. It occurs when the pressure inside the pump drops too low. This can cause severe damage. Keep an eye on inlet pressure levels. Ensure proper installation to avoid low-pressure conditions. Tips: Ensure the suction line is unrestricted. Blockages can create unwanted pressure drops.

In conclusion, addressing these issues is crucial for pump longevity. Diagnostic tools can help identify faults early. Regular maintenance, and listening to the pump can save time and costs in the long run.

Best Practices for Optimizing Pump Efficiency and Longevity

To achieve optimal performance with hydraulic diaphragm pumps, following best practices is crucial. Regular maintenance checks can prevent costly downtime. Inspect seals and diaphragms frequently for wear and tear. This simple action can boost efficiency significantly. Keeping an eye on fluid levels is equally important. Low fluid levels can lead to overheating and damage.

Operating the pump within recommended parameters is essential. Running at too high or too low pressure can shorten its lifespan. Understand the specific requirements of your application. Adjustments may be necessary to improve performance. Don’t ignore unusual noises or vibrations; they often indicate underlying problems. Responding to these signs promptly can save you time and money.

Training staff on proper operation of the pump is vital. Knowledgeable operators can make informed decisions. This reduces the risk of misuse or accidents. Creating a log for maintenance records can help identify trends over time. Reflection on these records may reveal patterns. It’s an opportunity to improve future practices and enhance the pump's longevity.

Related Posts

-

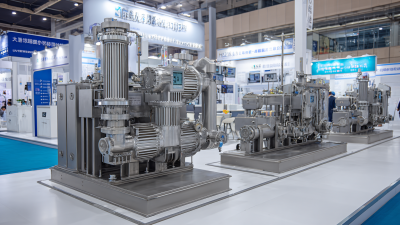

Exploring the Impact of Diaphragm Metering Pumps at the 138th China Import and Export Fair 2025

-

Understanding the Advantages of Hydraulic Diaphragm Pumps in Modern Industrial Applications

-

Exploring the Latest Innovations in Pump Products: Enhancing Efficiency and Sustainability

-

Top 10 Best High Pressure Chemical Pumps for Optimal Performance

-

High Pressure Dosing Pump Tips for Effective Use and Maintenance?

-

Top 7 Expert Tips for Using High Pressure Diaphragm Pumps Effectively