Blog

- Home

- Blog

Unlocking Efficiency: How High Pressure Pumps Revolutionize Industrial Processes

In the fast-paced realm of industrial processes, the adoption of High Pressure Pumps has emerged as a transformative solution driving efficiency and productivity. Recent industry reports indicate that the global high-pressure pump market is expected to reach USD 3.9 billion by 2026, growing at a CAGR of 6.5% from 2021. This growth is fueled by increasing demands for advanced manufacturing techniques across sectors such as oil and gas, chemical processing, and water treatment. High Pressure Pumps not only enable more effective fluid handling but also enhance energy efficiency, a crucial factor as industries strive to reduce operational costs and minimize environmental impact.

By unlocking new levels of performance, these pumps are revolutionizing traditional processes, paving the way for innovations that support sustainable industrial growth and meet the emerging challenges of the 21st century.

Importance of High Pressure Pumps in Modern Industry

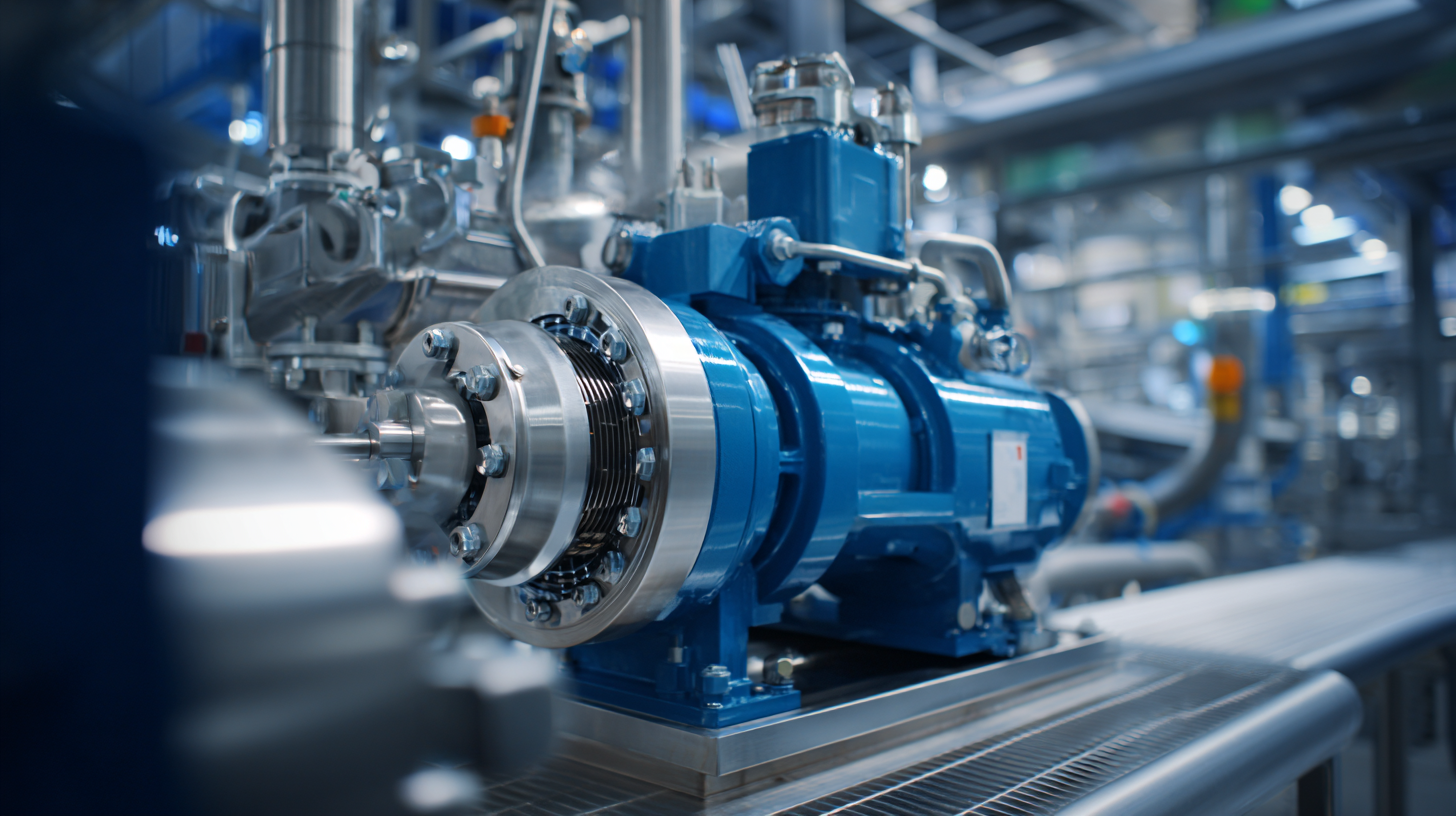

High pressure pumps play a crucial role in modern industry, transforming numerous processes across various sectors. From manufacturing to oil extraction, these pumps enhance efficiency and productivity by delivering fluids at elevated pressures. This capability allows for precise control over material flow, ensuring that operations run smoothly and effectively. Furthermore, high pressure pumps contribute to energy savings by reducing the amount of energy required to transport fluids over long distances.

**Tip:** When selecting a high pressure pump, consider the specific requirements of your application. Factors such as flow rate, pressure rating, and fluid characteristics are essential for optimizing performance.

In addition to improving operational efficiency, high pressure pumps also foster innovation in industrial applications. For example, they enable advanced techniques like water jet cutting, which can precisely slice through tough materials while minimizing waste. This adaptability not only increases manufacturing capabilities but also supports sustainable practices by reducing the environmental impact.

**Tip:** Regular maintenance of high pressure pumps is vital. Implement a routine inspection schedule to ensure optimal performance and prevent costly downtime.

Types of High Pressure Pumps and Their Specific Applications

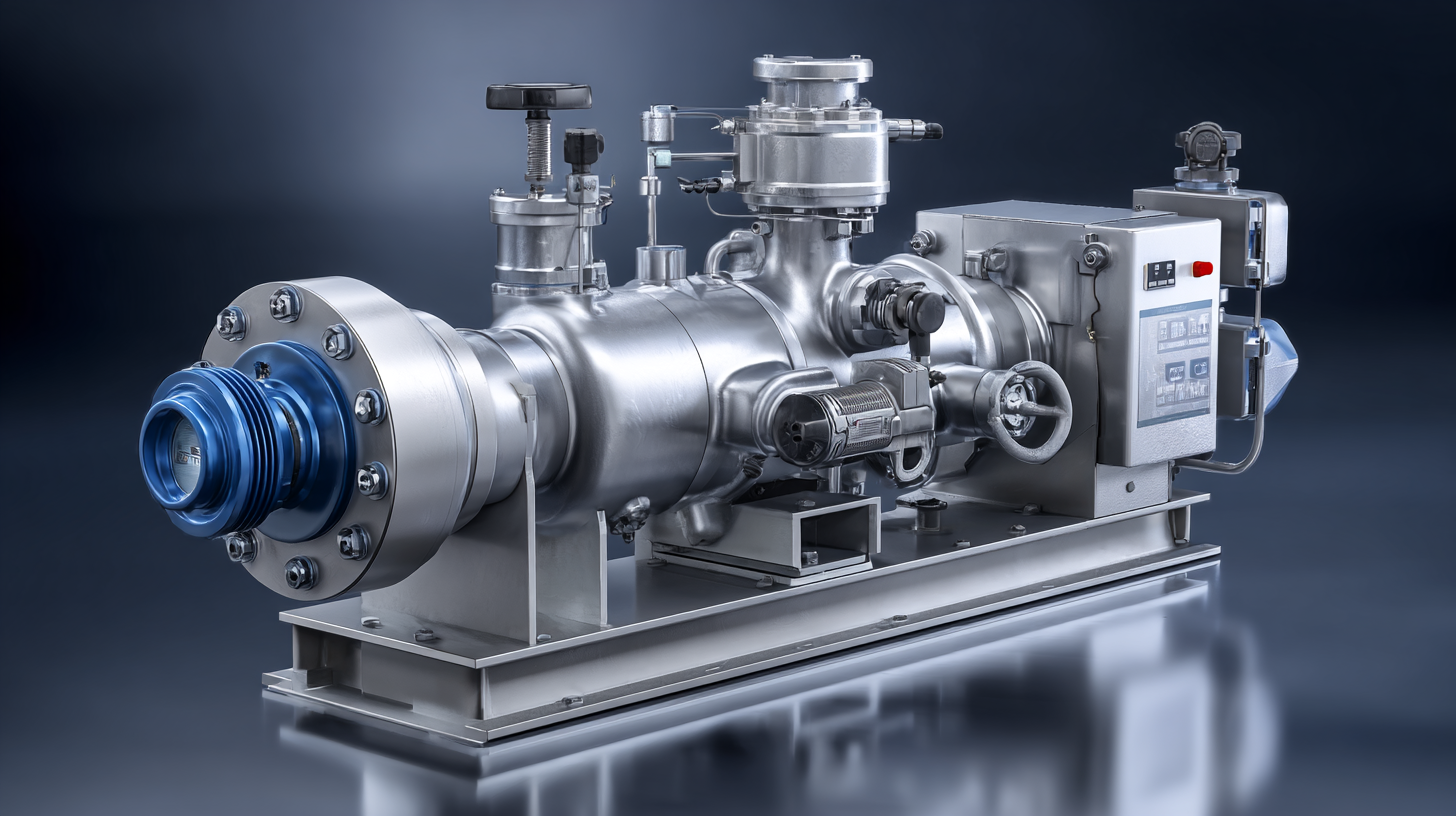

High pressure pumps play a crucial role in various industrial processes, with different types tailored for specific applications. The high pressure mud pump market, for instance, was valued at $320 million in 2022 and is projected to reach $510 million by 2030, achieving a compound annual growth rate (CAGR) of 7.4% from 2024 to 2030. These pumps are primarily utilized in drilling operations and are vital for the efficient extraction of resources.

Another significant category is cryogenic pumps, which are essential for transporting gases like nitrogen and oxygen at extremely low temperatures. The analysis of the cryogenic pump market shows a growing demand, indicative of advancements in energy and industrial sectors as they aim to enhance efficiency. As industries strive to innovate and increase productivity, the expected growth in the hydraulic pump market from $107.59 billion in 2025 to $146.61 billion by 2033, at a CAGR of 4.8%, highlights the vital role that high pressure pumps will continue to play in transforming industrial applications.

Unlocking Efficiency: How High Pressure Pumps Revolutionize Industrial Processes - Types of High Pressure Pumps and Their Specific Applications

| Pump Type | Operating Pressure (psi) | Flow Rate (GPM) | Applications |

|---|---|---|---|

| Positive Displacement Pump | 500 - 15,000 | 2 - 500 | Oil and gas, chemical processing, food processing |

| Centrifugal Pump | 100 - 5,000 | 10 - 1,000 | Water treatment, HVAC systems, irrigation |

| Plunger Pump | 1,000 - 10,000 | 0.5 - 200 | Hydraulic testing, pressure washing, food industry |

| Diaphragm Pump | 100 - 1,500 | 1 - 40 | Pharmaceuticals, wastewater treatment, chemical transfer |

| Jet Pump | 30 - 2,500 | 5 - 150 | Deep well pumping, hydrocarbon extraction, aquaculture |

Advantages of High Pressure Pumps Over Traditional Pumping Solutions

High pressure pumps have become an essential component in modern industrial processes, offering significant advantages over traditional pumping solutions. One of the primary benefits is their ability to handle high viscosity fluids and achieve greater flow rates, resulting in improved efficiency and productivity. This capability is particularly valuable in applications such as oil and gas, chemical manufacturing, and food processing, where materials often require robust handling to maintain flow consistency.

Additionally, high pressure pumps are designed for durability and reliability, often featuring advanced materials and engineering that allow them to operate in demanding environments. Unlike conventional pumps that may compromise performance over time, high pressure pumps can sustain their efficiency under strenuous conditions, reducing the need for frequent maintenance and downtime. This reliability not only enhances operational efficiency but also contributes to significant cost savings, allowing industries to maximize their output and maintain competitiveness in the market.

Unlocking Efficiency: High Pressure Pumps vs. Traditional Pumping Solutions

Challenges in Implementing High Pressure Pumps in Industrial Settings

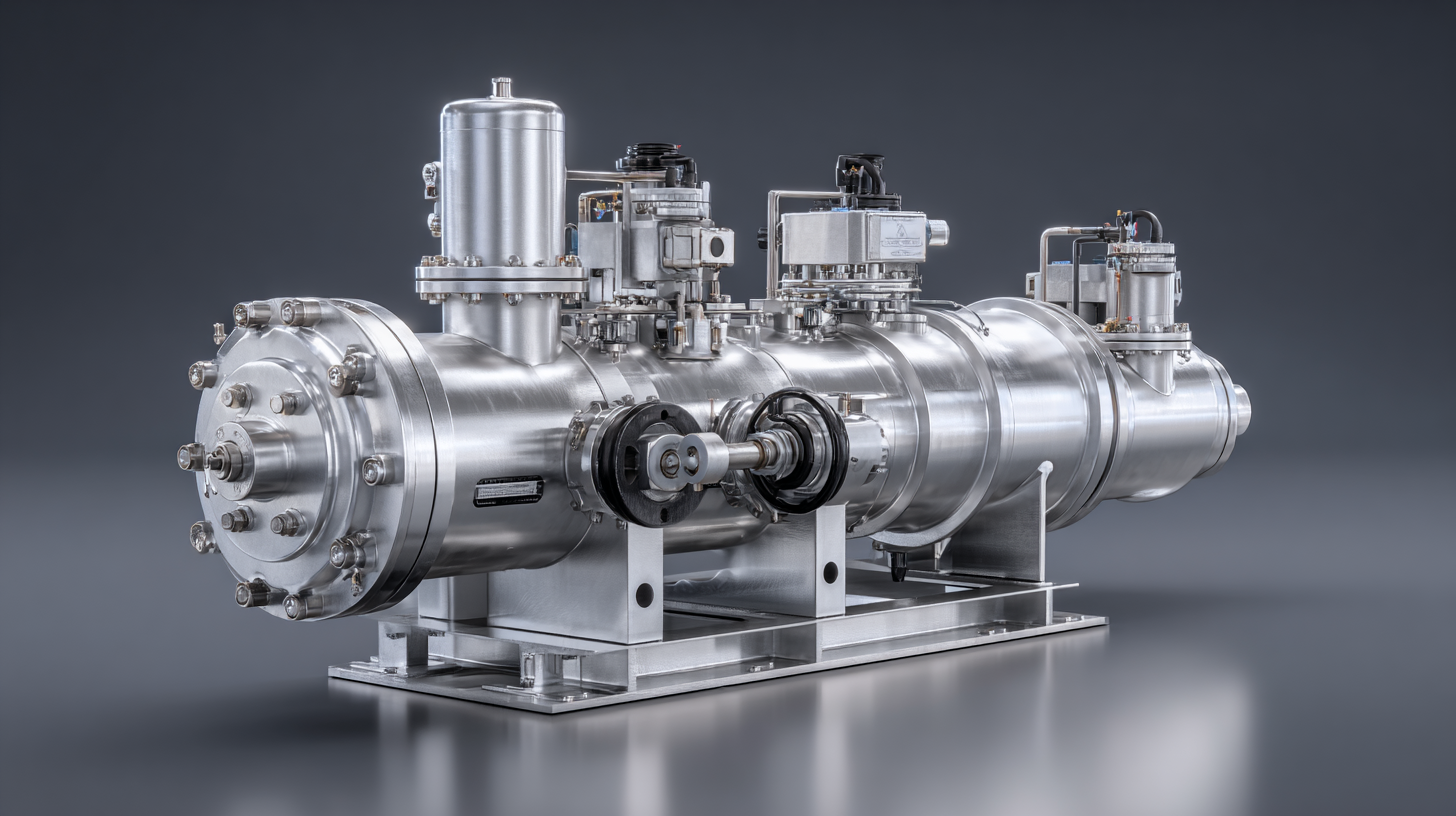

Implementing high-pressure pumps in industrial settings presents several challenges, despite their potential to enhance efficiency significantly. One of the primary issues is the initial investment and integration costs. High-pressure pumps are critical in applications such as hydraulic fracturing, which has revolutionized the extraction processes in the oil and gas sector. As the global market for high-pressure pumps is projected to grow from USD 3.02 billion in 2025 to USD 4.11 billion by 2033, an increasing number of industries are recognizing the importance of these systems. However, the complexity of installation and the need for specialized training can deter many organizations.

Additionally, ensuring the longevity and reliability of high-pressure pumps poses another challenge. Continuous operation under extreme conditions can lead to wear and maintenance difficulties, impacting productivity. Industrial players must also navigate regulatory restrictions and safety standards, particularly in sensitive applications such as natural gas extraction or waste heat recovery methods. For instance, as seen in a Scottish distillery that halved its CO2 emissions through waste-heat recovery, leveraging high-pressure systems requires not only technological adaptation but also compliance with environmental regulations that ensure sustainable operations. Addressing these challenges is crucial for companies looking to harness the full benefits of high-pressure pump technology in their processes.

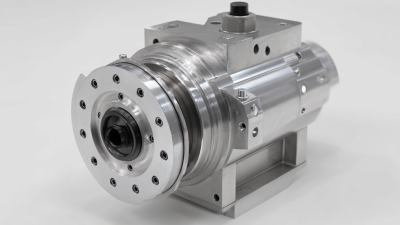

Future Trends and Innovations in High Pressure Pump Technology

High pressure pumps are set to play a crucial role in the evolution of industrial processes, driven by emerging trends and innovations in technology. The projected growth in various pump markets, such as the household water pump market expected to reach $18.58 billion by 2024 and $26.92 billion by 2032, highlights the increasing demand for efficient pumping solutions. The hydraulic pump market also shows a promising trajectory, with an expected rise from $1.0759 billion in 2025 to $1.46611 billion by 2033, maintaining a compound annual growth rate of 4.8%. These trends indicate not only the robustness of these markets but also the vital role high pressure pumps will play in enhancing operational efficiency across industries.

Tips: As industries adapt to new pressures, investing in high pressure pump technology can lead to significant advancements in performance and productivity. Embracing innovations such as semiconductor technologies in battery management systems can further integrate high pressure pumps into automated industrial setups, increasing overall operational efficiency. Companies aiming to harness these capabilities should prioritize research and development to stay ahead of the curve and meet evolving market demands.

Related Posts

-

How to Choose the Right High Pressure Pump for Your Industrial Needs

-

Understanding the Benefits of High Flow Hydraulic Pump in Modern Industrial Applications

-

How to Choose the Right Dosing Pump for Your Industrial Needs Based on Flow Rates and Chemical Compatibility

-

5 Essential Tips for Maximizing Performance of High Pressure Hydraulic Pumps

-

How to Choose the Best Chemical Pumps for Your Industrial Needs

-

Understanding the Benefits of High Pressure Diaphragm Pumps in Industrial Applications