Blog

- Home

- Blog

High Pressure Hydraulic Pump What You Need to Know

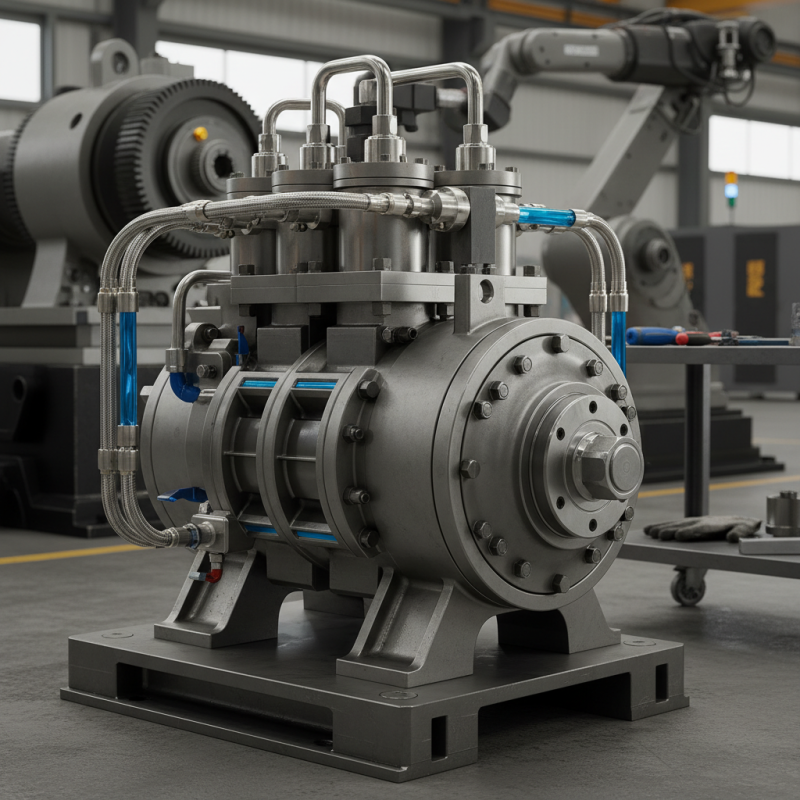

A High Pressure Hydraulic Pump is a vital component in various industrial applications. These pumps are designed to handle fluids at elevated pressures. They play a crucial role in powering machinery and can improve efficiency and performance.

Understanding the features and operation of a High Pressure Hydraulic Pump is essential. These devices can deliver powerful force, yet they require careful handling. Users often face challenges, such as selecting the right pump and maintaining it properly. Inconsistent maintenance can lead to performance issues and reduced lifespan.

Choosing the right High Pressure Hydraulic Pump is not always straightforward. Factors like flow rate and pressure rating must be considered. Inaccurate calculations can result in equipment failure. This makes it important to fully understand your needs before making any decisions. Knowledge is key to making the right choice.

Understanding High Pressure Hydraulic Pumps: A Comprehensive Overview

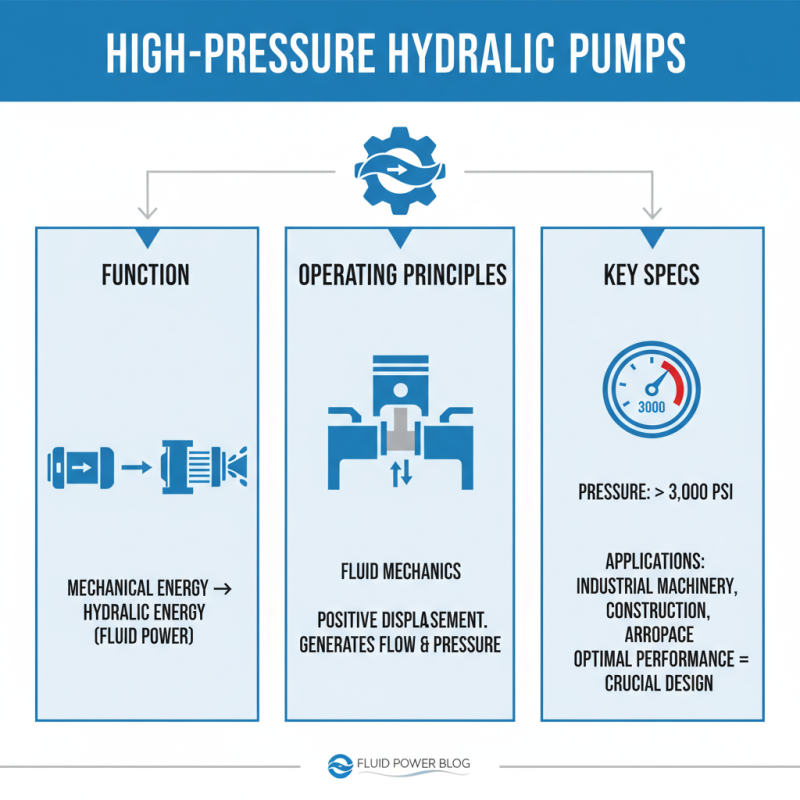

High pressure hydraulic pumps are vital in various industries. They mainly convert mechanical energy into hydraulic energy. This process relies on fluid mechanics principles. These pumps operate under high pressure, typically exceeding 3,000 psi. Understanding their design and function is crucial for optimal performance.

Users should be aware of common issues. Leaks can occur at seals, potentially leading to pressure drops. Debris in the fluid can also cause pump damage. Regular maintenance checks are essential. This helps in identifying wear and tear before it becomes serious. Look out for unusual noises; they can signal problems. However, not all issues are easily detectable.

Proper installation is equally important. Placement affects pump efficiency. An improper setup might lead to cavitation, which damages the pump. Users often overlook this detail. Training staff on these aspects is beneficial. It's not just about using the pump; it’s about understanding it. A good grasp of maintenance and care ensures longevity and reliability.

Key Components of High Pressure Hydraulic Pumps and Their Functions

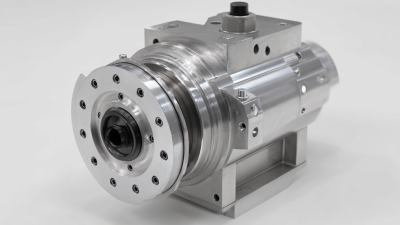

High pressure hydraulic pumps are essential in various industrial applications. Understanding their key components is crucial for effective maintenance and operation. The main components include the pump housing, drive mechanism, and hydraulic circuit connections.

The pump housing is designed to withstand intense pressures, often exceeding 5,000 psi. It contains the internal parts and keeps hydraulic fluid contained. The drive mechanism converts mechanical energy into hydraulic energy. This can be electric motors or combustion engines. Such components must be robust, as failure can lead to catastrophic results.

Hydraulic circuit connections, such as fittings and hoses, link the pump to the system. Poor connections can cause leaks or ruptures. Industry reports suggest that around 25% of hydraulic failures are due to improper assembly in these areas. Regular checks are necessary. Even small damages can escalate quickly. Awareness of these components helps in preemptive maintenance and reduces downtime, enhancing overall efficiency.

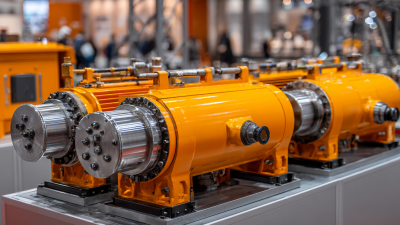

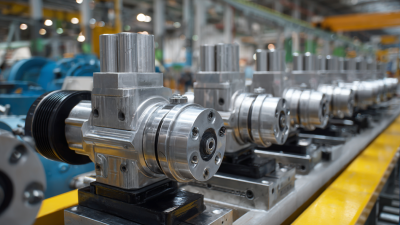

Common Applications of High Pressure Hydraulic Pumps in Various Industries

High pressure hydraulic pumps are essential in various industries. They deliver pressurized fluid to perform critical tasks. For instance, in the construction sector, these pumps play a crucial role in operating heavy machinery. According to a recent market analysis, the hydraulic pump market is expected to grow at a CAGR of 5.6% from 2021 to 2028. This growth reflects the increasing demand for efficient construction equipment.

Manufacturing is another domain where high pressure hydraulic pumps thrive. They are commonly used in metal forming and plastic molding applications. Reports indicate that about 30% of manufacturing processes involve hydraulic systems. However, challenges exist. Many firms struggle with pump maintenance. Regular checks can enhance performance and extend lifespan. Yet, many wait until breakdowns occur. This reactive approach can lead to costly downtime.

In the automotive industry, high pressure hydraulic pumps are indispensable. They assist in component assembly and testing. A survey revealed that around 40% of automotive manufacturers rely on hydraulic systems. However, the dependency raises concerns about energy efficiency. Many pumps are not operating at their ideal efficiency levels. This results in unnecessary energy consumption. Addressing these inefficiencies should be a priority for companies aiming for sustainability.

High Pressure Hydraulic Pumps: Common Applications Across Industries

Maintenance Tips for Ensuring Optimal Performance of Hydraulic Pumps

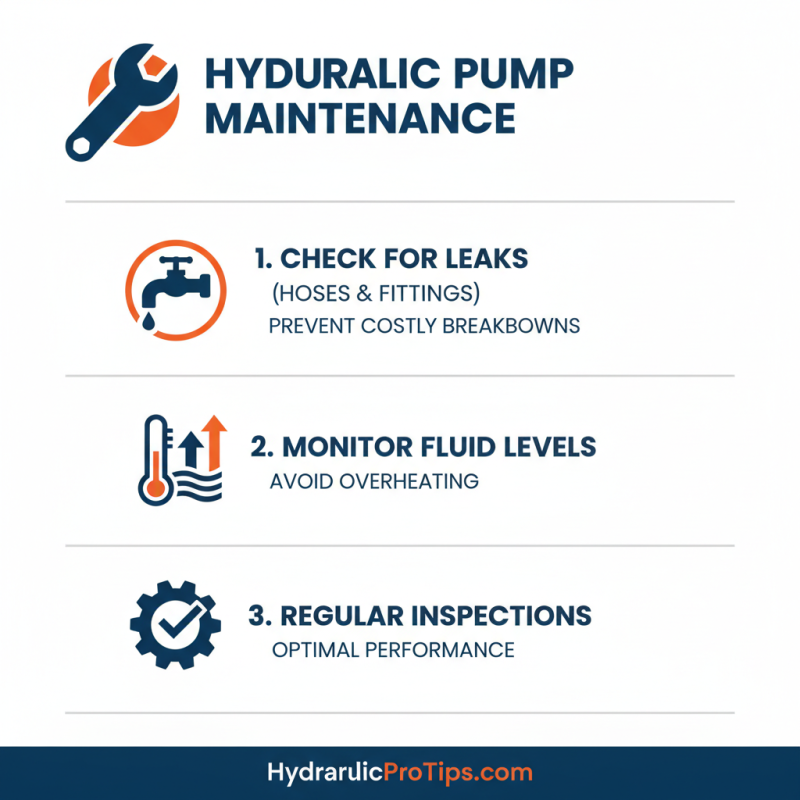

Maintaining a high pressure hydraulic pump is crucial for its performance. Regular checks can prevent costly breakdowns. Look for leaks around hoses and fittings. A small drip can indicate a larger problem. Monitor the fluid levels too. Low fluid can lead to overheating.

Fluid cleanliness is vital. Contaminants can harm pump components. Change the fluid according to the manufacturer's schedule. Filters should also be replaced regularly. Dirty filters can restrict flow and reduce efficiency. Don't ignore unusual noises. They could signal an underlying issue.

It’s important to check the pump's mounting and alignment. Misalignment can cause excessive wear. Vibration may indicate something is off. Regular visual inspections will help catch these issues early. Don’t let small problems escalate into major repair needs. Keeping a log of maintenance can help identify patterns over time.

Safety Considerations When Using High Pressure Hydraulic Pumps

High pressure hydraulic pumps are essential in various industries. However, safety must always be a priority. These pumps operate at pressures exceeding 1500 psi, presenting risks of equipment failure and personal injury. According to the Hydraulic Institute, improper handling can cause severe accidents, leading to injuries that account for 30% of workplace incidents.

Operators must wear appropriate safety gear. Items like gloves, goggles, and steel-toed boots can significantly reduce the risk of injury. It's crucial to inspect the equipment regularly. A study indicated that 40% of hydraulic failures come from improper maintenance. Neglecting routine checks can have disastrous consequences.

Training is essential for all users. Workers need to understand the specific hazards. They should know how to respond to emergencies. Inadequate training has been linked to increased accident rates. Some may overlook the need for continuous education. This oversight can lead to avoidable mistakes. Safety practices are not just guidelines; they are necessities that save lives.

Related Posts

-

How to Choose the Right Hydraulic Pump for Your Industrial Needs

-

5 Best Tips for Choosing the Right Hydraulic Pump for Your Needs

-

How to Optimize Your Hydraulic Pump System for Maximum Efficiency

-

5 Essential Tips for Maximizing Performance of High Pressure Hydraulic Pumps

-

Understanding the Benefits of High Flow Hydraulic Pump in Modern Industrial Applications

-

Understanding the Essential Role of Pump Hydraulic Systems in Modern Machinery