Blog

- Home

- Blog

What is a High Pressure Hydraulic Pump and How Does It Work?

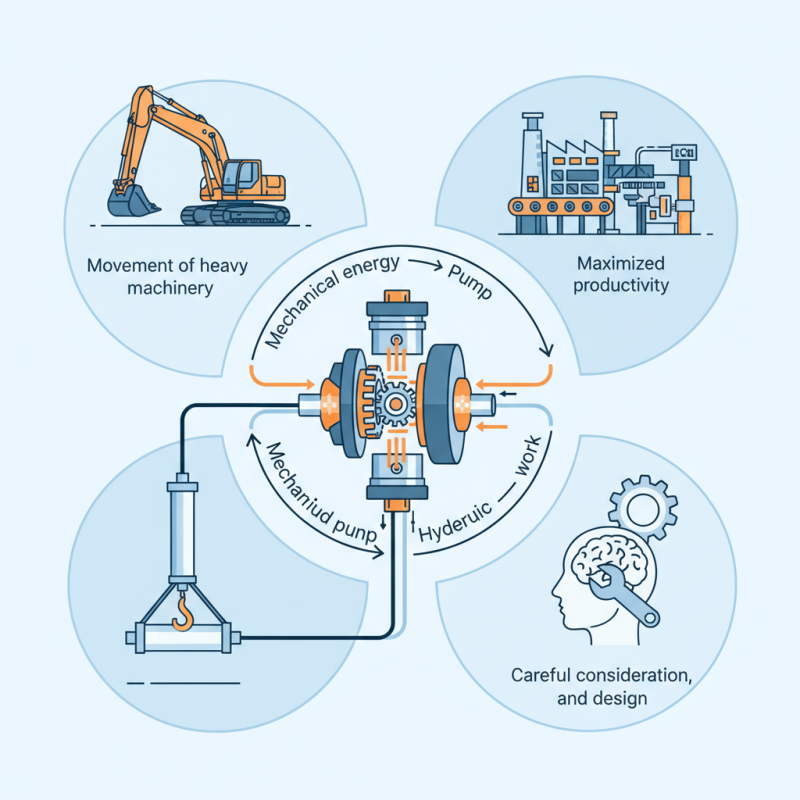

High Pressure Hydraulic Pumps are crucial in various industrial applications. These pumps generate high-pressure fluid used in multiple systems. According to John Smith, a renowned expert in hydraulic systems, "The efficiency of a High Pressure Hydraulic Pump is essential for successful operations." His insight underscores the importance of these pumps in maximizing productivity.

These pumps operate by converting mechanical energy into hydraulic energy. Through this process, they produce significant pressure, enabling the movement of heavy machinery and equipment. The workings of these units are complex, yet their impact on industries is profound. It's fascinating to see how they drive processes that seem simple yet rely on intricate technology.

As industries grow, the demand for effective High Pressure Hydraulic Pumps increases. However, not all pumps function flawlessly. Some may experience failures due to poor maintenance or design flaws. This calls for careful consideration when selecting and using these essential tools. Understanding their operation helps prevent costly mistakes.

What is a High Pressure Hydraulic Pump?

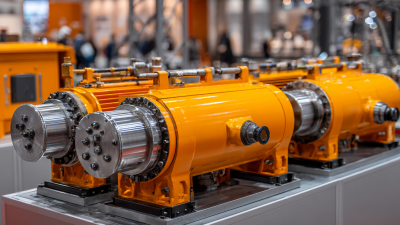

A high pressure hydraulic pump is a crucial component in hydraulic systems. It converts mechanical energy into hydraulic energy. This process enables heavy machinery to function effectively. Typically, these pumps operate at pressures exceeding 3,000 psi. They are essential in various industries, including construction, agriculture, and automotive.

According to a report by the International Fluid Power Society, the global hydraulic pump market is expected to grow significantly. Data suggests an annual growth rate of about 5% over the next five years. This growth indicates a rising demand for high-pressure systems. These systems provide increased efficiency and power control in hydraulic applications.

Many people overlook the complexities involved in hydraulic systems. The choice of hydraulic fluid is essential for optimal performance. It influences the pump's effectiveness and lifespan. A misguided selection could lead to pump failure. Understanding the detailed specifications and requirements is vital. Many operators may skip this process, leading to costly repairs and inefficiencies. Addressing these issues is crucial for maintaining high pressure hydraulic systems.

Components of a High Pressure Hydraulic Pump

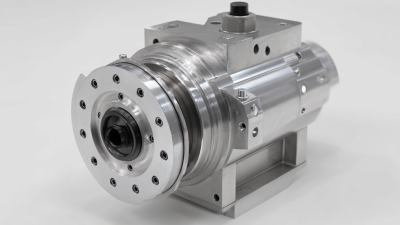

A high pressure hydraulic pump is designed to create hydraulic pressure for various applications. The components of these pumps work together to achieve efficient performance. Each part plays a crucial role in the system’s function.

The main components are the motor, pump body, and valves. The motor powers the pump and converts electrical energy into mechanical energy. It usually connects to the pump via a shaft. The pump body houses the internal mechanisms and helps generate pressure. Valves control the flow of fluid, directing it where needed. These valves must ensure that the fluid transfers smoothly.

Additionally, there are seals and filters involved. Seals prevent leaks and maintain pressure, which can be a challenge. Filters keep the hydraulic fluid clean, but they require regular maintenance. Over time, they can become clogged. These systems work well, but issues can arise if neglected. Regular inspection and care are necessary to keep everything functioning properly.

What is a High Pressure Hydraulic Pump and How Does It Work? - Components of a High Pressure Hydraulic Pump

| Component | Function | Materials Used | Typical Pressure Range (psi) |

|---|---|---|---|

| Pump Housing | Encases internal components and contains hydraulic fluid | Steel, Aluminum | 1500 - 3000 |

| Piston/Rotating Element | Generates pressure by converting mechanical energy | Carbon Steel, Hardened Plastics | 2000 - 5000 |

| Seals | Prevents hydraulic fluid leakage and maintains pressure | Nitrile Rubber, Viton | N/A |

| Intake and Discharge Valves | Control the flow of hydraulic fluid in and out of the pump | Brass, Stainless Steel | N/A |

| Reservoir | Holds hydraulic fluid to supply the pump | Plastic, Metal | N/A |

How High Pressure Hydraulic Pumps Generate Pressure

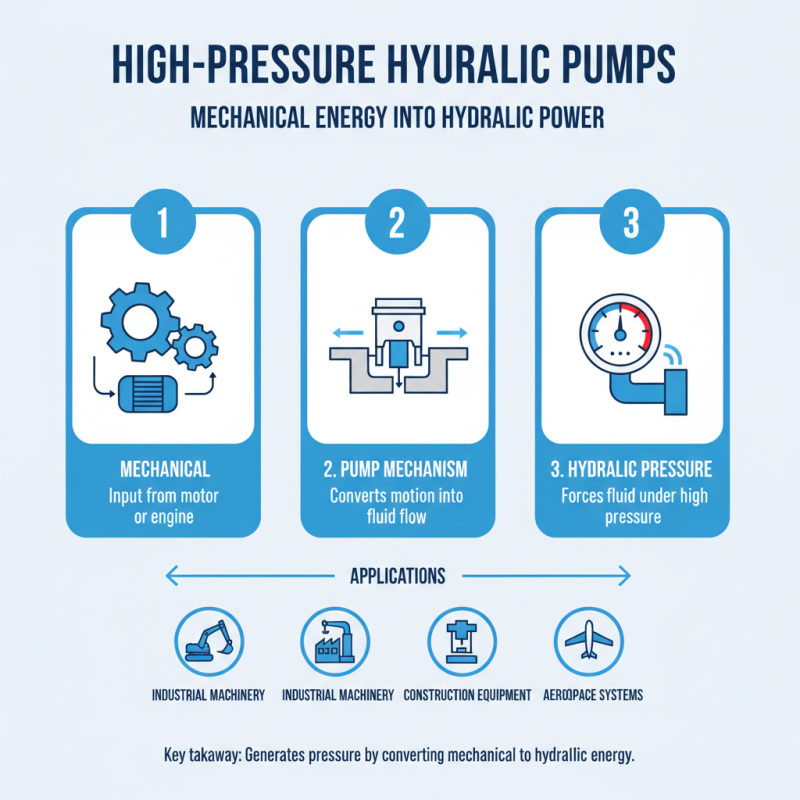

High pressure hydraulic pumps are powerful tools commonly found in various applications. These pumps work by converting mechanical energy into hydraulic energy. Understanding how they generate pressure is essential.

Hydraulic pumps operate using a principle called Pascal's law. This law states that pressure applied to a fluid in a confined space is transmitted equally in all directions. When the pump's motor drives the piston or gear, it creates a vacuum. This vacuum draws hydraulic fluid from the reservoir. As the fluid enters the pump, it gets compressed, which increases its pressure.

Tips: Always monitor fluid levels. Low fluid can cause pump failure. Regular maintenance is crucial. Check for leaks and clean filters often.

High pressure is beneficial but can also be risky. If pressure exceeds safety limits, it can damage equipment. Each system has its maximum threshold. Understanding these limits can prevent accidents. Overpressure situations require immediate attention. Don't ignore warning signs, as they can lead to failures.

Common Applications of High Pressure Hydraulic Pumps

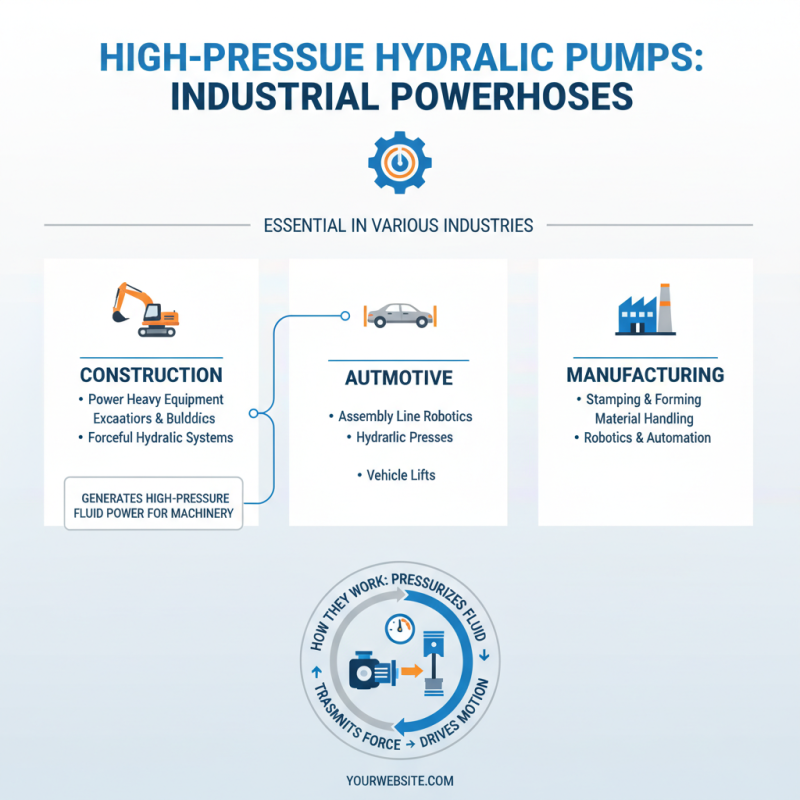

High pressure hydraulic pumps are essential in various industries. They generate high-pressure fluid power for machinery. These pumps are commonly used in construction, automotive, and manufacturing sectors. In construction, they power heavy equipment like excavators and bulldozers. These machines often require forceful hydraulic systems, making high-pressure pumps a necessity.

In automotive applications, these pumps support systems like power steering and braking. They enhance vehicle safety and efficiency. Furthermore, manufacturing plants use high-pressure hydraulic pumps for automated machinery. They help in processes like metal forming and assembly lines. This not only improves precision but also increases productivity.

However, the reliance on high pressure hydraulic pumps can raise questions. Are operators properly trained to manage these machines? Misuse can lead to potential hazards. Regular maintenance is crucial to prevent failures. Understanding the limitations of these systems is equally important. It encourages safer practices and better outcomes.

Maintenance and Troubleshooting Tips for Hydraulic Pumps

Hydraulic pumps are vital in many industrial applications. Regular maintenance can prevent costly failures. According to a report by the National Fluid Power Association, improper maintenance accounts for about 30% of hydraulic pump failures. This is a significant percentage, highlighting the importance of proactive care.

Inspecting hydraulic fluid levels is crucial. Low fluid levels can lead to cavitation, damaging the pump. Changing the oil regularly is also necessary. Fluid contaminated with particles can hinder performance. A recent study found that 80% of pump failures were related to fluid contamination. Users should monitor the health of hydraulic fluids diligently.

Troubleshooting is essential for efficient pump operation. If the system loses pressure, check for leaks or air ingress. Unusual noises can indicate internal damage. Timely detection is key. Operators should maintain a log of maintenance activities and issues. This helps in identifying recurring problems. It requires time and effort but can save money and extend pump life. Regular audits of pump performance might reveal unexpected trends. Awareness of these factors improves pump reliability significantly.

High Pressure Hydraulic Pump Efficiency Analysis

This chart represents the efficiency of various high-pressure hydraulic pumps based on their operating pressures (in psi) and corresponding flow rates (in GPM). The data highlights the relationship between pressure and flow for optimal performance.

Related Posts

-

5 Best Tips for Choosing the Right Hydraulic Pump for Your Needs

-

5 Essential Tips for Maximizing Performance of High Pressure Hydraulic Pumps

-

How to Optimize Your Hydraulic Pump System for Maximum Efficiency

-

7 Best Practices for Choosing a High Pressure Metering Pump

-

How to Choose the Right Hydraulic Pump for Your Industrial Needs

-

Understanding the Benefits of High Flow Hydraulic Pump in Modern Industrial Applications