Blog

- Home

- Blog

High Pressure Dosing Pump Tips for Effective Use and Maintenance?

High Pressure Dosing Pumps are essential in various industries, from chemical processing to water treatment. According to a recent report by MarketsandMarkets, the global dosing pump market is projected to reach USD 6.57 billion by 2027. This growth emphasizes the importance of understanding effective usage and maintenance of High Pressure Dosing Pumps. Proper handling can significantly impact performance and longevity.

Effective use of High Pressure Dosing Pumps requires knowledge of operational parameters. Small adjustments can lead to substantial differences in efficiency. Common mistakes, such as incorrect calibration or inadequate maintenance, can reduce pump reliability. For instance, neglecting routine inspections may lead to wear and tear. These issues can also result in costly downtime.

Maintenance is a critical aspect often overlooked. Regular checks on seals, valves, and hoses can prevent leaks and failures. A study indicated that up to 30% of pump failures are due to improper maintenance practices. Understanding these dynamics is vital for users. High Pressure Dosing Pumps are powerful tools. However, without careful attention, their potential may remain untapped.

High Pressure Dosing Pump Overview: Types and Applications

High pressure dosing pumps are essential in various industries, including water treatment, pharmaceuticals, and food processing. They ensure precise chemical dosing, enhancing efficiency and safety. According to a report from Market Research Future, the global dosing pump market is expected to grow at a CAGR of 5.6% from 2021 to 2027. This growth indicates the increasing demand for reliable and accurate dosing solutions.

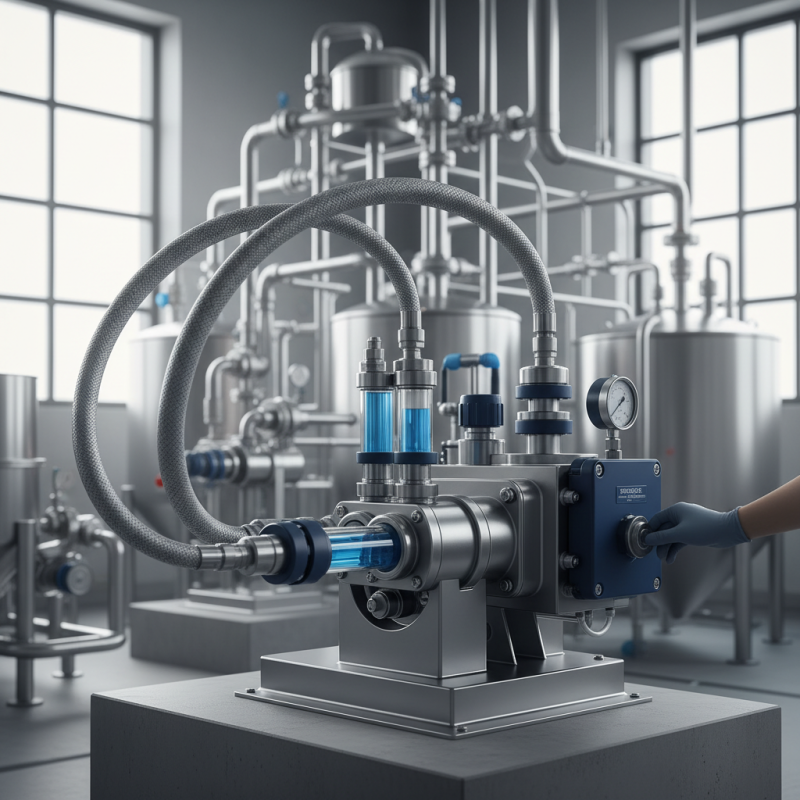

There are several types of high-pressure dosing pumps, such as piston, diaphragm, and gear pumps. Each has unique applications. Diaphragm pumps, for instance, excel in handling corrosive substances. They can operate at high pressures, typically ranging from 3,000 to 15,000 psi. However, regular maintenance is critical to avoid wear and tear. Neglecting maintenance may result in pump inefficiencies and potential downtime, which can be costly.

In practice, operators should pay attention to the material compatibility of the pump. Using incorrect materials can lead to leaks or pump failure. Studies indicate that about 20% of pump failures stem from poor material choices. Additionally, maintaining proper pressure settings can greatly improve the pump’s lifespan. Even minor adjustments can lead to significant performance gains, but operators must constantly monitor these settings. Maintenance records indicate that a proactive approach can extend pump life by 30%. Noticing these details can mean the difference between optimal performance and frequent repairs.

High Pressure Dosing Pump Performance Comparison

This bar chart illustrates the flow rate performance of different high pressure dosing pump models. Each pump shows varying capacities, useful for comparing options in applications requiring specific flow rates.

Key Factors Influencing High Pressure Dosing Pump Performance

High-pressure dosing pumps play a critical role in various industrial applications. Their performance depends on several key factors. One major factor is the pump's design. A well-designed pump can withstand high pressures without failures. Another important element is the fluid being pumped. Viscosity and chemical composition can significantly affect pump efficiency. Moreover, operating conditions like temperature and pressure need to be monitored closely.

Tips for effective use include regular maintenance checks. Scheduled inspections can help identify potential issues before they become major problems. Check seals and fittings for wear. Replacing these parts promptly can prevent leaks. Additionally, always ensure that the pump operates within its specified parameters. Operating outside these limits can lead to premature failure.

Another tip is to keep an eye on flow rates. Fluctuations can indicate underlying problems. Consistency in flow is vital for reliable operation. Routine calibration may be necessary to maintain accuracy. Lastly, consider environmental factors. Vibration and noise can signal impending malfunction. Regularly assessing these signs can lead to better performance and longevity of the pump.

Essential Maintenance Practices for High Pressure Dosing Pumps

High pressure dosing pumps are vital in various industries. Their efficiency relies on proper maintenance. Regular checks are essential to ensure optimal performance. Pay attention to seals and gaskets. Worn-out parts can lead to leaks. Replacing them promptly can save costs in the long run.

Cleaning is another crucial aspect. Build-up of residues can hinder functionality. Schedule routine cleaning sessions. Use appropriate solvents for safe results. Monitor the pump’s pressure readings consistently. Unusual fluctuations may indicate underlying issues. Addressing them early can prevent costly downtime.

Operators often overlook lubrication. Lack of adequate lubrication can cause friction and wear. Ensure that moving parts receive the right amount. Review the maintenance manual frequently. Staying informed is key to effective upkeep. Remember; cutting corners today may lead to bigger problems tomorrow.

High Pressure Dosing Pump Tips for Effective Use and Maintenance

| Maintenance Practice | Frequency | Recommended Tools | Notes |

|---|---|---|---|

| Inspect Pump Seals | Monthly | Visual Inspection Tools | Check for wear and tear to prevent leaks. |

| Clean Filter Screens | Bi-weekly | Soft Brush, Water | Ensure unobstructed flow into the pump. |

| Calibrate Flow Rate | Quarterly | Flow Meter, Calibration Equipment | Maintain accurate dosing performance. |

| Lubricate Moving Parts | Monthly | Lubricant, Applicator | Prevent wear and ensure smooth operation. |

| Check Electrical Connections | Monthly | Multimeter, Screwdriver | Avoid electrical failures and ensure safety. |

Common Issues and Troubleshooting Techniques for Dosing Pumps

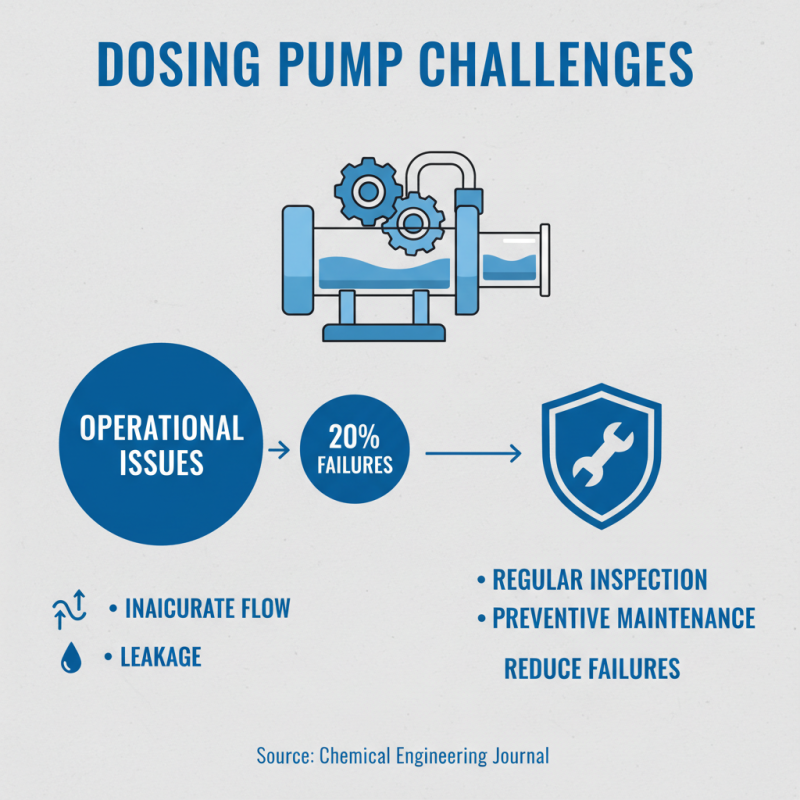

Dosing pumps are vital in various industries, ensuring accurate chemical delivery. However, they often face common challenges. According to a report from the Chemical Engineering Journal, nearly 20% of dosing pump failures stem from operational issues. These include inaccuracies in flow rates and leakage problems. Regular inspection and preventive maintenance can significantly reduce these failures.

Leakage is a frequent issue that can arise from worn seals or improper installation. It is critical to monitor the pump for any signs of fluid escape. Regularly checking connections and seals can prevent larger disruptions. A study by the American Institute of Chemical Engineers highlighted that many facilities overlook simple maintenance tasks, leading to costly downtime.

Another common problem involves pulsation in the flow. Pulsation can affect the chemical dosage accuracy. Adding dampeners or adjusting the pump speed can help mitigate these issues. It's essential to analyze pump performance data regularly. Ignoring these details may lead to significant inefficiencies and increased operational costs. Each facility's unique needs require tailored approaches to optimal dosing pump performance.

Industry Standards and Compliance for High Pressure Dosing Pumps

When utilizing high pressure dosing pumps, adherence to industry standards is crucial. The American Society of Mechanical Engineers (ASME) sets rigorous guidelines for pump design and performance. Compliance with ASME standards ensures safety and efficiency. According to a recent report, 30% of industrial pumps fail to meet these standards, resulting in costly downtime.

It's vital to understand the specifications and requirements outlined in relevant industry reports. The Hydraulic Institute provides detailed guidelines for pump operation, categorizing pumps by function and application. Following these guidelines can significantly reduce risk. For instance, operating pressure levels must adhere to recommendations. Operating outside these levels can cause premature wear or even catastrophic failure.

Inadequate training can also be a concern. A survey found that 40% of operators lack formal training. This gap in knowledge can lead to improper maintenance practices. Regular inspections and routine checks can help mitigate future issues. It is essential to cultivate an environment of continuous learning and improvement. Operational efficiency can significantly enhance when proper protocols are followed.

Related Posts

-

Understanding the Importance of High Pressure Dosing Pumps in Modern Industries

-

Unlocking Efficiency: How High Pressure Pumps Revolutionize Industrial Processes

-

Top 10 Industrial Metering Pumps: Key Features, Market Trends, and User Insights for 2023

-

Top 7 Expert Tips for Using High Pressure Diaphragm Pumps Effectively

-

Top 10 Best High Pressure Chemical Pumps for Optimal Performance

-

How to Choose the Right Plunger Pump for Your Industrial Needs