Blog

- Home

- Blog

Exploring the Latest Innovations in Pump Products: Enhancing Efficiency and Sustainability

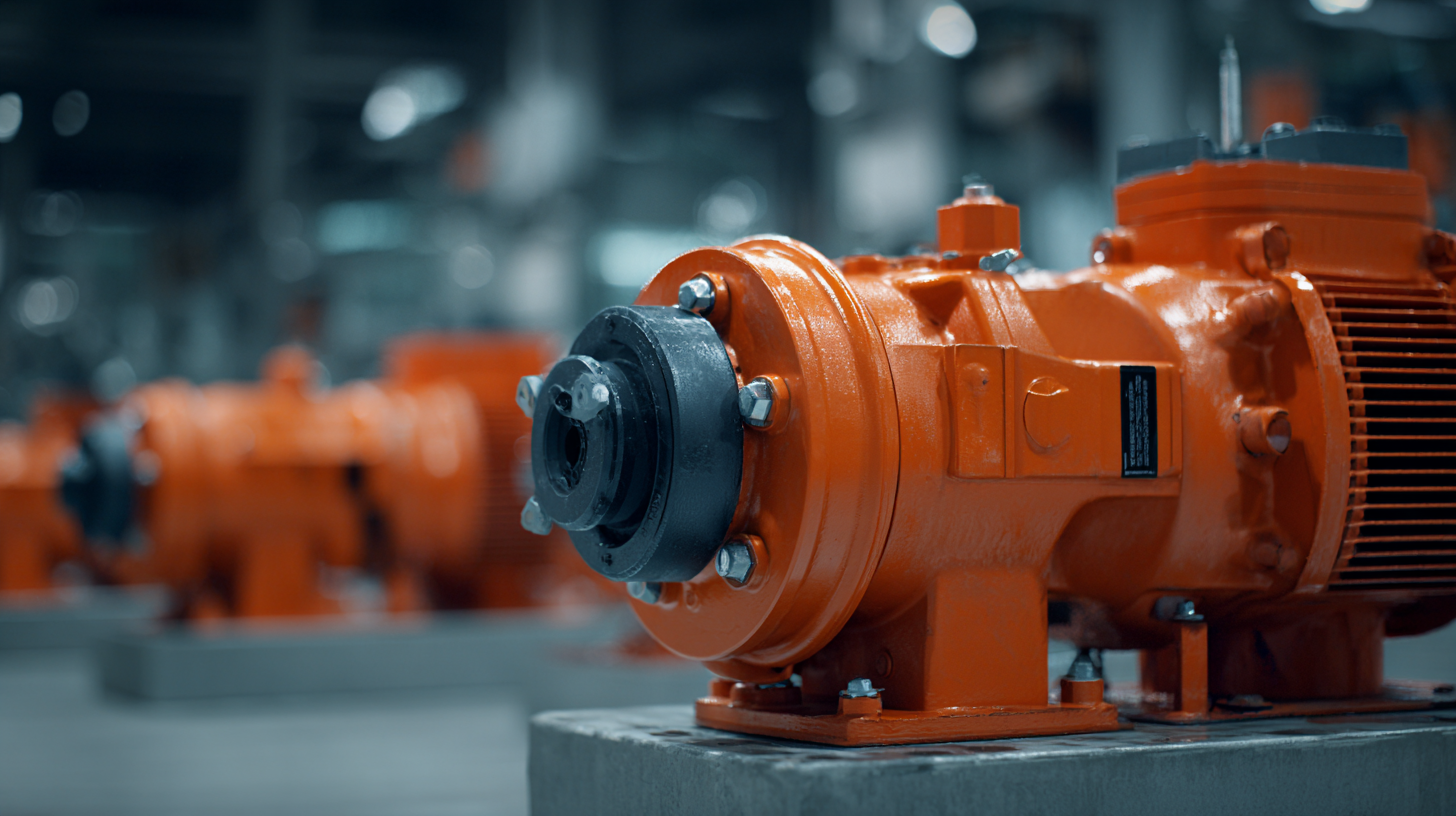

In recent years, the global pump products market has witnessed substantial advancements driven by the urgent need for enhanced efficiency and sustainability. According to a report by MarketsandMarkets, the pump market is projected to reach USD 104.1 billion by 2025, reflecting a compound annual growth rate (CAGR) of 3.5%. This growth is propelled by innovations in technology, such as smart pumps that utilize IoT capabilities for real-time monitoring and optimized performance. Furthermore, the increasing demand for eco-friendly solutions has led manufacturers to focus on energy-efficient designs and materials that minimize environmental impact. As industries continue to prioritize operational efficiency and renewable practices, exploring the latest innovations in pump products will be crucial for achieving sustainability goals while meeting the demands of a rapidly evolving marketplace.

Identifying Key Trends in Pump Technology for Improved Performance

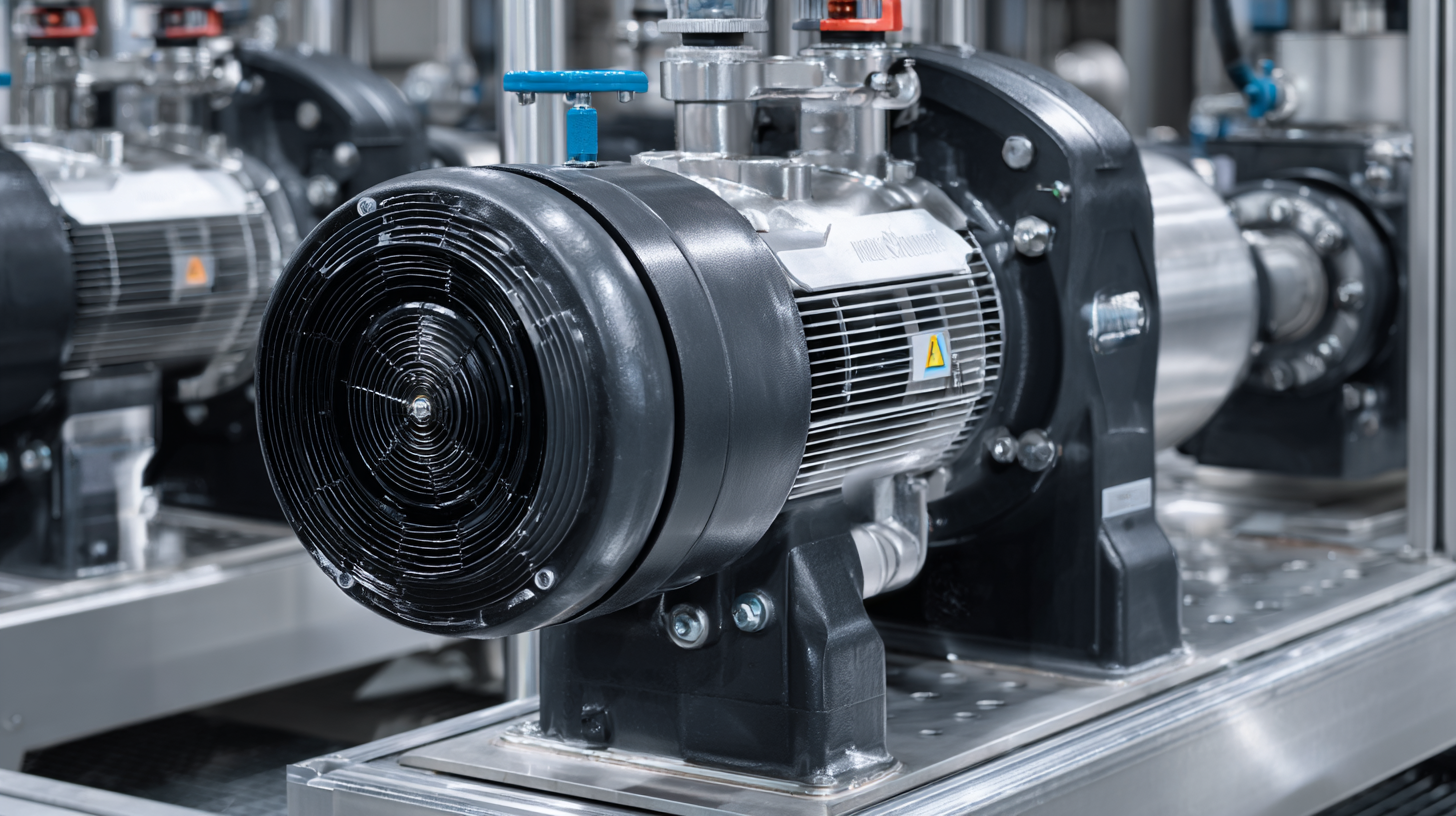

Recent advancements in pump technology are marked by a strong focus on enhancing performance and sustainability. One of the key trends is the integration of smart technology and IoT capabilities into pumping systems. These innovations allow for real-time monitoring and data analysis, enabling operators to optimize the performance of pumps. By utilizing predictive maintenance algorithms, industries can significantly reduce downtime and enhance the overall efficiency of their operations. This shift not only leads to cost savings but also supports environmentally sustainable practices by minimizing energy consumption.

Another significant trend is the development of advanced materials for pump construction. Manufacturers are increasingly using lightweight, corrosion-resistant materials that improve durability and reduce the environmental impact associated with traditional materials. Additionally, energy-efficient designs, such as variable speed drives and optimized impeller geometries, have emerged, contributing to more sustainable fluid handling processes. As industries adopt these state-of-the-art technologies, the focus on creating pumps that deliver high performance while adhering to sustainability goals becomes ever more pivotal.

Evaluating the Role of Smart Features in Pumps for Enhanced Efficiency

The integration of smart features into pump products is significantly transforming the landscape of efficiency and sustainability. Advanced sensors and IoT technology allow pumps to continuously monitor their operating conditions, leading to real-time data analysis. This capability not only optimizes energy consumption but also enhances performance across various applications. By adjusting operational parameters based on real-time feedback, smart pumps can reduce wear and tear, extending their lifespan while minimizing downtime.

The integration of smart features into pump products is significantly transforming the landscape of efficiency and sustainability. Advanced sensors and IoT technology allow pumps to continuously monitor their operating conditions, leading to real-time data analysis. This capability not only optimizes energy consumption but also enhances performance across various applications. By adjusting operational parameters based on real-time feedback, smart pumps can reduce wear and tear, extending their lifespan while minimizing downtime.

Tips: To maximize the benefits of smart pumps, consider implementing a regular maintenance schedule that leverages the data provided by these devices. Routine analyses of performance metrics can identify potential issues before they escalate, saving both time and resources.

Moreover, these innovative pump features can facilitate better control over fluid systems, enabling automated adjustments that align with changing operational needs. This adaptability not only contributes to increased efficiency but also supports sustainability efforts by reducing waste and energy usage. As industries continue to prioritize eco-friendly solutions, the role of smart pumps will become increasingly vital in achieving these goals.

Tips: When selecting a pump, look for models that offer advanced analytics and remote monitoring capabilities. This can greatly improve decision-making processes and enhance overall operational efficiency.

Assessing Sustainable Materials and Manufacturing Processes in Pump Production

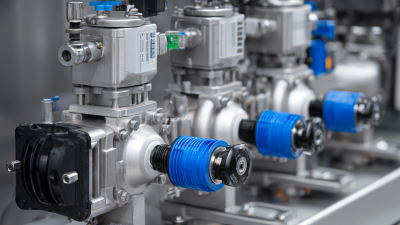

Recent advancements in pump production have focused heavily on the integration of sustainable materials and eco-friendly manufacturing processes. Companies are increasingly adopting biomaterials and recycled components in pump design, which not only reduces environmental impact but also enhances durability and performance. For instance, the use of thermoplastics derived from renewable sources offers an attractive alternative to traditional metals, significantly lowering the carbon footprint associated with production.

Moreover, innovations in manufacturing techniques, such as additive manufacturing and precision machining, have emerged as game-changers in the industry. These methods enable the design of more efficient pumps that minimize waste during production and offer the flexibility to customize designs for specific applications. By leveraging digital technologies and smart manufacturing principles, companies can ensure that their processes align with sustainability goals, contributing to a greener environment while maintaining high efficiency standards in their pump products.

Exploring Energy Recovery Solutions in Modern Pump Systems

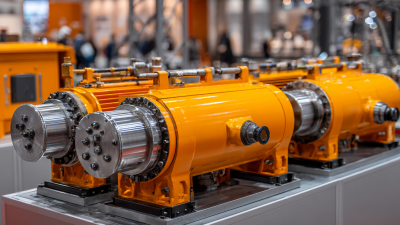

Modern pump systems are at the forefront of energy recovery solutions, significantly contributing to enhanced efficiency and sustainability in various industries. As indicated in a recent report, the industrial heat pump market is projected to reach USD 371.52 billion by 2035, growing at a CAGR of 6.37%. This surge reflects an increasing commitment from industries to transition toward energy-efficient heating solutions, ultimately driving down carbon emissions. Moreover, energy efficiency is now recognized as the "first fuel" in clean energy transitions, delivering some of the most immediate and cost-effective reductions in CO2 emissions.

Energy recovery systems are integral in sectors like desalination, where energy consumption can account for up to 60% of operational costs. Innovations in pump technology enable more effective management of thermal energy, paving the way for sustainable practices in water treatment processes. For instance, recent advancements in heat recovery systems are not only enhancing plant efficiency but also playing a crucial role in the broader movement toward decarbonizing our urban environments.

Tips:

- Consider implementing smart HVAC systems that optimize energy usage while maintaining comfort.

- Regularly assess and upgrade pump systems to leverage the latest energy recovery technologies, boosting overall operational efficiency.

- Explore partnerships focusing on renewable energy solutions to secure sustainable energy sources for critical infrastructure.

Implementing Maintenance Strategies for Long-term Pump Efficiency and Sustainability

The implementation of effective maintenance strategies is crucial for ensuring long-term efficiency and sustainability in pump operations. Regular maintenance not only extends the lifespan of pumps but also enhances their performance. Scheduled inspections should focus on identifying wear and tear in critical components, such as seals and bearings. By addressing potential issues before they escalate, facilities can minimize downtime and avoid costly repairs.

Moreover, adopting predictive maintenance techniques can significantly improve the reliability of pump systems. Utilizing advanced technologies such as vibration analysis, thermal imaging, and condition monitoring sensors allows operators to gather real-time data and anticipate failures. This proactive approach enables timely interventions, reducing energy consumption and increasing operational efficiency. As industries continue to prioritize sustainability, investing in robust maintenance strategies will play a pivotal role in achieving eco-friendly practices while ensuring optimal functioning of pump products.

Latest Innovations in Pump Products: Efficiency and Sustainability

This chart illustrates the percentage of energy efficiency improvements and sustainability innovations across different types of pump technologies from 2021 to 2023.

Related Posts

-

7 Best Industrial Pumps You Should Consider for Your Next Project

-

Exploring the Innovations in Industrial Pumps: How Cutting-Edge Technology is Revolutionizing Efficiency

-

8 Key Advantages of Diaphragm Pumps: Efficiency and Reliability in Fluid Management

-

What Makes Plunger Metering Pump Essential for Precision Fluid Control

-

Exploring Plunger Metering Pump Innovations at the 2025 China Import and Export Fair

-

How to Optimize Your Hydraulic Pump System for Maximum Efficiency