Blog

- Home

- Blog

10 Essential Tips for Choosing the Right High Pressure Hydraulic Pump

When selecting a high pressure hydraulic pump, understanding the intricacies of the industry is crucial. According to a recent report by the Global Hydraulic Pump Market Research, the demand for high pressure hydraulic pumps is projected to grow at a compound annual growth rate of 6.5% from 2022 to 2028, driven by innovations in technology and increasing applications across various sectors. These pumps are pivotal in numerous industries, from construction and mining to manufacturing and renewable energy, underscoring their significance in modern machinery and operations.

Expert in hydraulic systems, Dr. Emily Carter, states, “Choosing the right high pressure hydraulic pump is not just about specifications; it’s about understanding the application’s demands and the pump’s capabilities.” This emphasizes the complexity involved in selecting the appropriate pump. Factors such as pressure requirements, flow rates, and efficiency ratings must be meticulously evaluated to match the pump with the intended operational environment. With the growing intricacies of hydraulic systems and advancements in pump technology, it becomes increasingly vital for professionals to equip themselves with the essential knowledge needed to make informed decisions.

As we delve into the 10 essential tips for choosing the right high pressure hydraulic pump, it is imperative to consider these dynamics and insights from industry experts to ensure optimal performance and reliability in your applications.

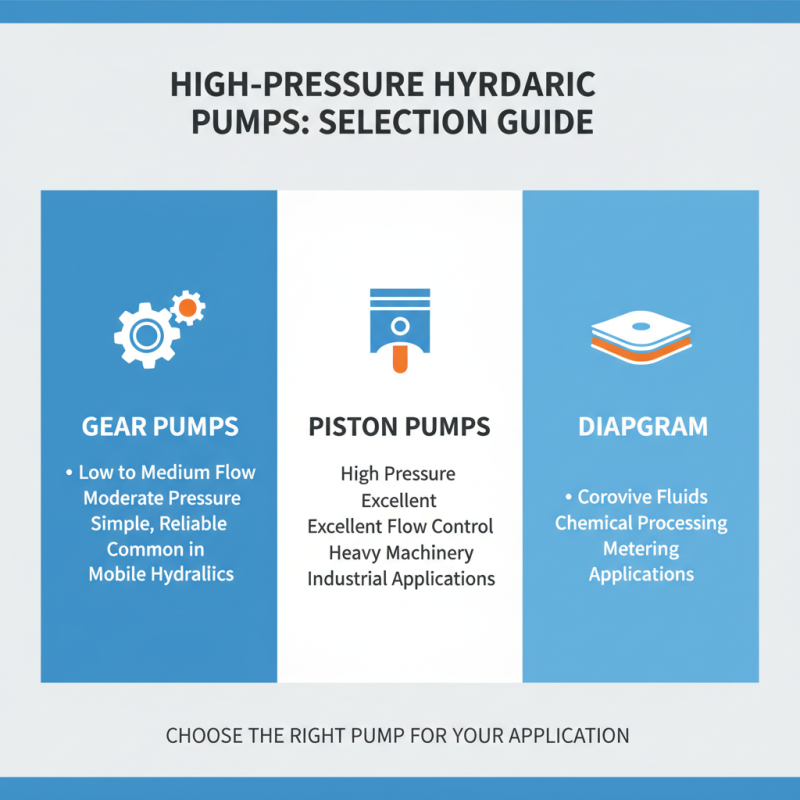

Types of High Pressure Hydraulic Pumps and Their Applications

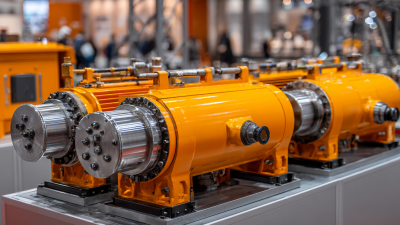

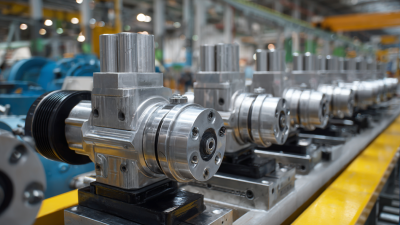

When selecting the right high pressure hydraulic pump, it's crucial to understand the various types available and their specific applications. High pressure hydraulic pumps generally fall into several categories, such as gear pumps, piston pumps, and diaphragm pumps. Gear pumps are commonly used for low to medium flow applications, thanks to their simplicity and reliability. They work efficiently in hydraulic systems with moderate pressure requirements. On the other hand, piston pumps are renowned for their ability to handle high pressure and provide excellent flow control, making them a popular choice in heavy machinery and industrial applications. Lastly, diaphragm pumps are ideal for transferring corrosive fluids and are often used in chemical processing industries.

When choosing the right pump, it’s important to consider the intended application and operating conditions. One key tip is to assess the pressure and flow rate requirements of your system before making a selection. This ensures that the pump can perform effectively without overloading. Another essential tip is to evaluate the fluid compatibility to avoid damage to the pump and system. Ensuring that you choose a pump designed for the specific fluid type can lead to better performance and longevity. Finally, don’t overlook the importance of maintenance. Selecting a pump that offers easy maintenance access can save time and reduce operational costs in the long run.

Key Factors to Consider When Selecting a Hydraulic Pump Model

When selecting a high-pressure hydraulic pump, several key factors should guide your decision-making process. First, consider the pump's flow rate and pressure specifications, as these determine the pump's effectiveness for your specific application. It's essential to align the pump's capabilities with the requirements of the hydraulic system it will service, ensuring optimal performance and efficiency. Additionally, take into account the viscosity of the fluid being pumped, as this can significantly impact the pump's choice and longevity.

Another crucial factor is the pump's construction materials and design. A well-built hydraulic pump should withstand the operating environment, including temperature extremes and exposure to contaminants. Evaluate the pump's maintenance needs, as ease of access for service can greatly affect downtime and operational costs. Lastly, examine the overall size and footprint of the pump in relation to your installation requirements. A pump that fits within the designated space without compromising functionality will ensure a smooth integration into your hydraulic system.

Understanding Hydraulic Pump Specifications and Ratings

When selecting a high-pressure hydraulic pump, understanding the specifications and ratings is crucial for optimizing performance and ensuring system compatibility. The flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), is one of the key specifications to consider. For instance, high-pressure hydraulic pumps typically operate effectively at flow rates ranging from 5 GPM to over 100 GPM, depending on the application scope. According to the International Hydraulic Association, flow rate directly influences the efficiency of hydraulic systems; mismatched flow rates can lead to increased wear or premature failure of hydraulic components.

Another vital specification is the pressure rating, which determines the maximum pressure the pump can safely handle. Most hydraulic pumps are rated between 1,500 psi to over 5,000 psi. Reports from the Hydraulic Institute indicate that maintaining the operating pressure within the manufacturer's specified limits is essential for longevity and reliability. Additionally, factors such as the material construction, pump design (gear, diaphragm, piston), and maintenance schedules greatly influence a pump's durability under high pressure. By carefully evaluating these specifications, you can significantly enhance the performance of hydraulic systems and avoid costly operational downtimes.

Maintenance and Care Tips for High Pressure Hydraulic Pumps

Proper maintenance and care of high pressure hydraulic pumps are critical for ensuring longevity and optimal performance. According to the International Fluid Power Society, regular maintenance can enhance the lifespan of hydraulic components by up to 30%. One important aspect of preventive maintenance is regular fluid checks. Hydraulic fluid should be monitored for contamination and viscosity, as these factors significantly impact pump efficiency. Contaminated fluid can lead to increased wear and potential pump failure, underscoring the need for filtration systems and periodic fluid changes.

Another vital maintenance practice involves routine inspections of seals and fittings. A study by the Fluid Power Research Center indicates that nearly 70% of hydraulic failures are attributed to leakage. Inspecting these components for wear and tear allows for timely replacements, preventing extensive damage and costly downtime. Moreover, specific care guidelines, such as avoiding exceeding the manufacturer's recommended pressure limits and ensuring proper alignment during installation, can mitigate operational risks. Adhering to these practices ensures that hydraulic pumps not only perform effectively but also maintain safety standards in industrial applications.

Common Mistakes to Avoid When Choosing a Hydraulic Pump

When selecting a hydraulic pump, avoiding common mistakes is crucial for ensuring optimal performance and longevity of your equipment. One frequent error is underestimating the pump's pressure requirements. Make sure to assess the specific needs of your application, as using a pump with insufficient pressure capabilities can lead to failure and costly downtime.

Another mistake to watch out for is neglecting the hydraulic fluid compatibility. Each hydraulic pump is designed to work with specific types of fluid, and using the wrong one can lead to damage or reduced efficiency. Always check fluid recommendations to ensure a proper match for the pump you plan to use.

One essential tip is to evaluate the pump's flow rate requirements. It’s vital to understand the flow needs of your system, as selecting a pump that does not meet these requirements can hinder performance. Additionally, consider the installation and maintenance aspects, as ease of access can significantly influence the ongoing upkeep of your system. Taking the time to address these factors can help you choose the right hydraulic pump and avoid pitfalls that could impact your operations.

Related Posts

-

5 Best Tips for Choosing the Right Hydraulic Pump for Your Needs

-

How to Optimize Your Hydraulic Pump System for Maximum Efficiency

-

How to Choose the Right Hydraulic Pump for Your Industrial Needs

-

Understanding the Essential Role of Pump Hydraulic Systems in Modern Machinery

-

10 Tips for Maximizing Efficiency with High Pressure Hydraulic Pumps in Industrial Settings

-

5 Essential Tips for Maximizing Performance of High Pressure Hydraulic Pumps