Blog

- Home

- Blog

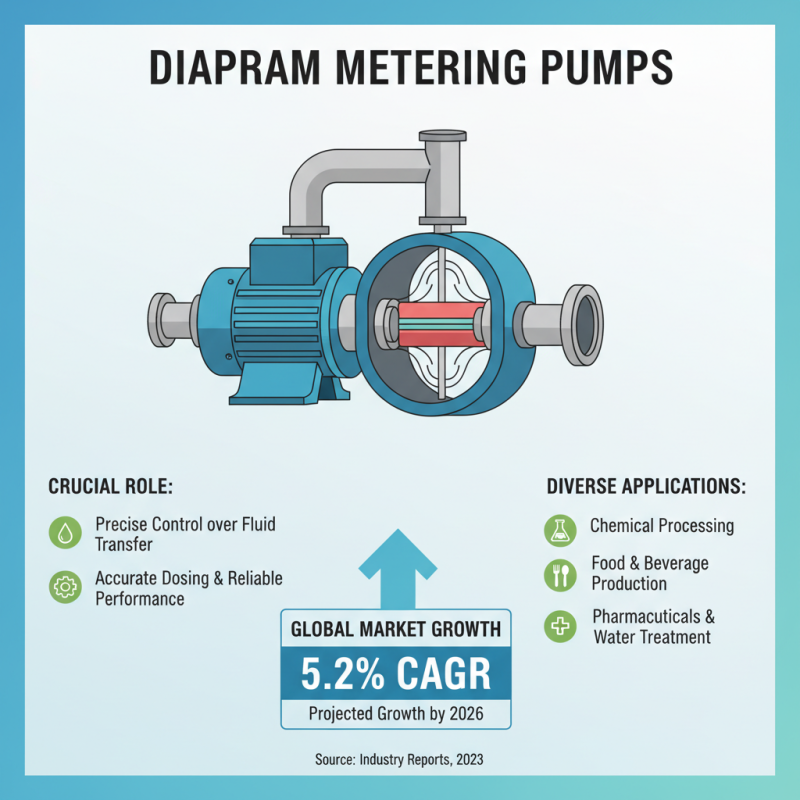

What is a Diaphragm Metering Pump and How Does It Work?

A Diaphragm Metering Pump is a crucial device in various industries. This pump type precisely controls fluid flow. Its unique design allows for accurate dosing of chemicals or other liquids. It consists of a flexible diaphragm that moves to create suction and pressure. This movement ensures precise amounts are delivered every time.

The operation of a Diaphragm Metering Pump involves a few simple yet effective principles. When the diaphragm flexes, it draws fluid into the chamber. As it moves back, the fluid is expelled through a discharge valve. This cycle continues, providing reliable performance. However, maintaining a Diaphragm Metering Pump can be challenging. Over time, wear and tear can affect accuracy and efficiency.

Industries benefit greatly from these pumps. They are widely used in water treatment, chemical processing, and agriculture. Yet, users must remain vigilant. Regular checks and maintenance are vital for optimal function. This ensures that the pump delivers the intended results without failure.

What is a Diaphragm Metering Pump?

A diaphragm metering pump is essential in various industries. It precisely pumps liquids at specific flow rates. This design ensures high accuracy, which is vital in applications like chemical dosing. The core of the pump is a flexible diaphragm. This diaphragm expands and contracts to create suction and discharge.

The simplicity of the pump hides its effectiveness. It can handle many fluids, including corrosive chemicals. However, it is not perfect. If the diaphragm wears out, leaks can occur. Regular maintenance is crucial to avoid operational issues. The pump also needs proper installation to function correctly. Misalignment may lead to inefficiency and unexpected downtime.

Diaphragm metering pumps are user-friendly. They often include intuitive controls. They can be adjusted for various applications, but some users may struggle with complex settings. A learning curve exists, as incorrect settings can lead to inaccurate dosing. Understanding each feature is important for optimal use. Each pump can provide great benefits when understood fully.

What is a Diaphragm Metering Pump and How Does It Work?

| Feature | Description |

|---|---|

| Definition | A diaphragm metering pump is a positive displacement pump used to dispense precise volumes of fluids. |

| Working Principle | It operates by flexing a diaphragm to create a vacuum that draws fluid in and then pushes it out through a discharge valve. |

| Applications | Used in water treatment, chemical dosing, food processing, and more. |

| Advantages | High accuracy, suitable for low and high viscosity fluids, and can handle corrosive materials. |

| Maintenance | Requires regular inspection of diaphragm and seals; simple to maintain. |

| Types | Includes air-operated, mechanical, and electrically operated models. |

| Flow Rate | Flow rates typically range from a few milliliters per hour to several thousand liters per hour. |

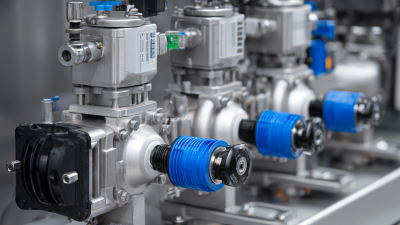

Key Components of a Diaphragm Metering Pump

Diaphragm metering pumps are vital in many industries. They provide precise control of fluid flow. The design relies on key components that ensure operational efficiency.

One major component is the diaphragm, which separates the fluid from the drive mechanism. This design prevents contamination of the chemicals being pumped. Diaphragms are made from various materials to handle different media, such as corrosive liquids. According to the 2023 Fluid Pump Index, around 40% of facilities prefer diaphragm pumps for their reliability in chemical dosing applications.

Another critical part is the hydraulic chamber. It works in tandem with the diaphragm, allowing for smooth, pulsation-free flow. The hydraulic chamber's design can affect the pump's overall efficiency and maintenance needs. Interestingly, recent data suggests that nearly 35% of pump failures stem from issues within this component. Therefore, regular inspection and timely replacement are essential for optimal performance.

Understanding these components can provide insights into potential operational issues. For instance, if the diaphragm wears out too quickly, the materials may not be compatible with the pumped liquid. Monitoring these factors can help mitigate unexpected downtime and maintenance costs.

Principle of Operation: How Diaphragm Pumps Work

Diaphragm metering pumps are essential in various industries for precise fluid handling. They use a flexible diaphragm to separate the liquid from the pump's mechanical components. This design avoids contamination, which is critical for sensitive processes. The diaphragm moves back and forth, creating a suction effect that draws liquid into the chamber. As it moves in the opposite direction, it forces the liquid out through the discharge valve.

The principle of operation centers on this diaphragm movement. It is typically driven by either an electric motor or a pneumatic actuator. The stroke length and speed determine the flow rate. Adjustments are often necessary to maintain accuracy. Users must consider wear on the diaphragm over time. Regular checks can prevent unexpected breakdowns. A worn diaphragm can lead to leaks and inconsistencies in flow.

In practice, maintaining these pumps can be challenging. Operator training is crucial to understanding the system’s demands. Indicators of wear are not always obvious. Sometimes, the diaphragm might show no visible wear yet fails under pressure. Fine-tuning the system often takes time and repeated testing. Balancing efficiency and accuracy requires continuous observation and adjustments.

Diaphragm Metering Pump Performance Analysis

This chart illustrates the performance parameters of Diaphragm Metering Pumps across various flow rates and pressures, showcasing how efficiency varies based on these factors.

Applications of Diaphragm Metering Pumps in Various Industries

Diaphragm metering pumps play a crucial role in various industries, providing precise control over fluid transfer. Their applications are diverse, ranging from chemical processing to food and beverage production. According to industry reports, the global diaphragm pump market is projected to grow significantly, with an expected CAGR of 5.2% by 2026. This growth reflects the increasing demand for accurate dosing and reliable performance in manufacturing processes.

In the chemical industry, these pumps are vital for handling corrosive substances. They ensure that chemicals are delivered with exact measurements. In water treatment facilities, diaphragm pumps help in the continuous metering of chemicals to purify water. Similarly, in pharmaceuticals, precise dosing is critical. A small error in measurement can lead to production mishaps.

Tip: Regular maintenance is essential for diaphragm metering pumps. This ensures optimal functioning and prevents costly downtime. Users should also consider the pump's compatibility with the fluid being pumped.

However, diaphragm metering pumps may have limitations. They can struggle with viscous fluids, leading to inaccuracies. Moreover, the initial cost can be higher compared to other types of pumps. Reflecting on these aspects helps in making an informed choice for specific applications.

Advantages and Limitations of Using Diaphragm Metering Pumps

Diaphragm metering pumps offer various advantages. They provide precise flow control, essential for many industries. These pumps can handle various fluid types, including corrosive or viscous substances. Their design minimizes leaks, ensuring a safer working environment. They work well in applications where accurate dosing is critical, such as chemical processing.

However, diaphragm metering pumps also have limitations. Their performance can vary with changes in viscosity or density of the fluid. Over time, the diaphragm may wear, leading to reduced efficiency. Some models may require regular maintenance, adding to operational costs. Users need to consider these factors carefully when selecting a pump for their application. Understanding both strengths and weaknesses is crucial for making an informed decision.

Related Posts

-

How to Select the Right Hydraulic Diaphragm Pump for Your Industrial Needs

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications

-

What Makes Plunger Metering Pump Essential for Precision Fluid Control

-

8 Key Advantages of Diaphragm Pumps: Efficiency and Reliability in Fluid Management

-

Exploring the Impact of Diaphragm Metering Pumps at the 138th China Import and Export Fair 2025

-

Understanding Diaphragm Pumps: Key Technologies and Their Impact on Fluid Transfer Efficiency