Blog

- Home

- Blog

Essential Tips for Choosing the Right Plunger Pump for Your Needs

When it comes to selecting the right plunger pump for your specific applications, it's essential to undertake a thorough evaluation of various factors that define pump performance and reliability. According to the latest industry reports from market research firms, the global plunger pump market is expected to grow significantly, driven by increasing demand in sectors such as oil and gas, water treatment, and industrial applications. The efficient operation of these pumps, which handle high-pressure tasks, relies heavily on the correct choice of specifications, materials, and configurations tailored to meet operational requirements.

In recent years, data highlights that the efficiency and durability of plunger pumps have become critical considerations, with users increasingly seeking pumps that not only fulfill immediate operational needs but also offer long-term reliability and cost efficiency. Studies indicate that investing in the right plunger pump can result in substantial operating cost savings, as well as minimized downtime. As the market evolves with advancements in technology, understanding the key features and benefits of plunger pumps is imperative for making informed decisions that align with specific business goals and environmental standards.

Understanding the Basics of Plunger Pumps and Their Applications

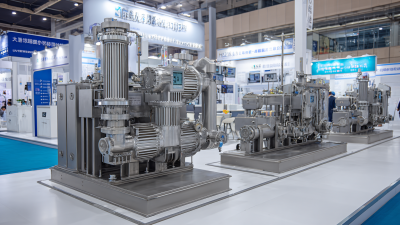

Plunger pumps are essential devices in various industries, designed to transfer fluids at high pressure. Understanding the fundamentals of plunger pumps is crucial for anyone considering their application. These pumps operate using a cylindrical plunger that moves within a sealed cylinder, creating a vacuum that draws in fluid during the suction stroke and expelling it during the discharge stroke. According to a recent report by the Global Market Insights, the plunger pump market is expected to grow at a compound annual growth rate (CAGR) of 6.7% from 2021 to 2027, driven by increased demand in sectors such as oil and gas, water treatment, and chemical processing.

Plunger pumps are notably versatile and can handle a wide range of fluids, including corrosive chemicals and viscous liquids. Their design allows for high efficiency and performance under varying conditions, making them suitable for applications in industrial cleaning, hydraulic systems, and even food processing. However, selecting the right plunger pump requires an understanding of factors such as flow rate, pressure needs, and the properties of the fluids being pumped. Research from the Pumps & Systems magazine emphasizes that improper pump selection can lead to decreased efficiency and increased maintenance costs, highlighting the importance of thorough analysis before making a decision. Properly matched, plunger pumps can significantly enhance system reliability and operational effectiveness across multiple applications.

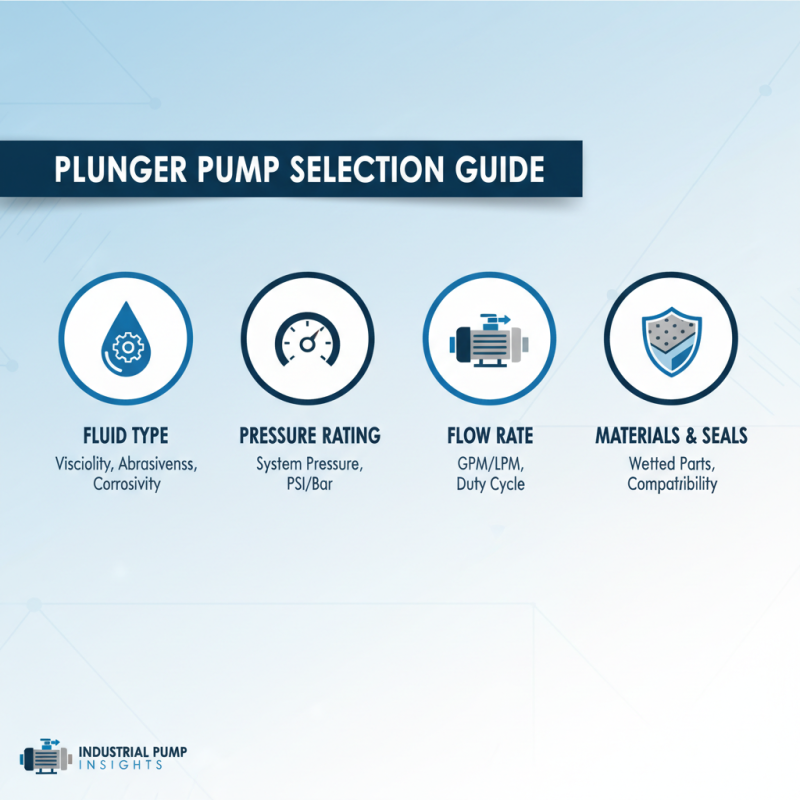

Key Factors to Consider When Selecting a Plunger Pump

When selecting a plunger pump, there are several key factors to consider to ensure you choose the right model for your specific requirements. First and foremost, it’s essential to understand the type of fluid you will be pumping, as this influences materials, pressure ratings, and design. For example, abrasive substances may necessitate more durable materials to avoid wear and tear, while corrosive fluids might require specific coatings or materials that withstand chemical reactions.

Additionally, the flow rate and pressure requirements of your application should guide your selection process. Evaluate the maximum flow rate your operations demand and ensure the chosen pump can meet those needs efficiently. It's also crucial to consider the operating environment. Factors such as temperature fluctuations, potential exposure to dust or moisture, and space limitations can affect both the performance and longevity of the pump. By carefully analyzing these aspects, you can make a well-informed choice that aligns with your operational goals and ensures reliable performance.

Comparing Different Types of Plunger Pumps for Various Needs

When it comes to selecting the right plunger pump for your needs, it's essential to compare the various types available to ensure maximum efficiency and performance. Plunger pumps are generally categorized based on their design and functionality, such as single-acting and double-acting pumps. Single-acting pumps are great for applications that require consistent flow without high-pressure demands, while double-acting pumps are designed to handle higher pressures with a more effective fluid output. Understanding the specific requirements of your project will help you make an informed decision.

While evaluating different types of plunger pumps, consider factors such as fluid type, viscosity, and temperature. A key tip is to ensure that the pump materials are compatible with the fluids being handled to prevent any potential chemical reactions or damages. Additionally, assess the expected volumetric flow rate and discharge pressure of the pump to align it with your operational needs. This will not only optimize performance but also extend the lifespan of the pump.

Another important aspect is maintenance. Opt for a pump that allows easy access to components for routine checks, as this can significantly reduce downtime. Regular maintenance is vital for ensuring the longevity and reliability of your chosen pump. By addressing these factors, you will be better equipped to select a plunger pump that meets your specific operational demands efficiently.

Maintenance Tips for Ensuring Optimal Performance of Plunger Pumps

Maintaining the optimal performance of plunger pumps is crucial for ensuring operational efficiency and longevity. Regular maintenance practices should include checking and replacing seals and O-rings, as these components are vital for maintaining pressure and preventing leaks. According to industry reports, improper sealing can lead to a 20% decrease in efficiency and an increase in energy consumption. Therefore, scheduling routine inspections—at least every six months for industrial applications—is recommended to address wear and tear before it affects performance.

Additionally, monitoring the pump's operating conditions can help identify potential issues early. Keeping an eye on parameters such as temperature, pressure, and flow rates is essential. For instance, fluctuations in pressure could indicate a blockage or wear in the components, prompting timely intervention. As per a recent survey by the Hydraulic Institute, 30% of pump failures are linked to operational anomalies, emphasizing the need for consistent monitoring. Proper lubrication is another key factor; using the right type and amount of lubricant can significantly extend the life of the pump and maintain its efficiency. Implementing these maintenance tips not only boosts performance but also reduces unplanned downtime and costly repairs.

Essential Tips for Choosing the Right Plunger Pump

This chart represents key performance metrics to consider when choosing a plunger pump. Flow rate, pressure, and efficiency are critical factors for functionality, while durability and maintenance frequency are important for long-term operation.

Common Mistakes to Avoid When Choosing a Plunger Pump

When selecting a plunger pump, it's crucial to avoid some common mistakes that can lead to inefficiencies or costly oversights. One prevalent error is neglecting the specific application requirements. Every pump serves different purposes and operates under varying conditions; failing to assess these factors can result in a mismatch. Before making a decision, ensure you fully understand the fluid characteristics, pressure requirements, and potential environmental factors. This thorough analysis will help in selecting a pump that operates effectively and efficiently.

Another frequent mistake is underestimating the importance of maintenance and operational costs. Often, buyers focus solely on the initial purchase price, overlooking long-term expenses like upkeep and energy consumption. It's essential to evaluate how different models compare in terms of reliability, repair needs, and overall lifecycle costs. A seemingly cheaper option may lead to higher costs down the line due to increased wear or operational inefficiencies. By taking into account the total cost of ownership, you can make a more informed choice that aligns with your financial and operational goals.

Essential Tips for Choosing the Right Plunger Pump for Your Needs - Common Mistakes to Avoid When Choosing a Plunger Pump

| Feature | Importance | Common Mistake | Tip to Avoid Mistake |

|---|---|---|---|

| Pump Type | Performance efficiency | Choosing the wrong type for application | Understand your application needs before selecting |

| Material Compatibility | Durability and function | Ignoring material interactions | Check compatibility with fluids being pumped |

| Pressure Rating | Operation safety | Underestimating pressure needs | Calculate maximum pressure required for the system |

| Flow Rate | Efficiency measurement | Not assessing flow requirements | Determine the flow rate based on application |

| Maintenance Requirements | Longevity and performance | Underestimating maintenance needs | Review maintenance schedule and requirements |

Related Posts

-

Understanding Common Issues Faced by Users of Plunger Pumps

-

How to Choose the Right Plunger Pump for Your Industrial Needs

-

10 Tips for Maximizing Efficiency with High Pressure Hydraulic Pumps in Industrial Settings

-

Understanding the Benefits of High Pressure Diaphragm Pumps in Industrial Applications

-

Exploring the Impact of Diaphragm Metering Pumps at the 138th China Import and Export Fair 2025

-

How to Select the Right Hydraulic Diaphragm Pump for Your Industrial Needs