Choosing the right Chemical Dosing Pump is crucial for ensuring precision and efficiency in your fluid management systems. Whether you are handling water treatment, chemical processing, or other industrial applications, selecting a pump that meets your specific needs can significantly impact your operational success.

With various alternatives available on the market, it can be overwhelming to pinpoint the most suitable option. Different types of pumps offer unique advantages and functionalities tailored to specific applications, which makes thorough research essential.

With various alternatives available on the market, it can be overwhelming to pinpoint the most suitable option. Different types of pumps offer unique advantages and functionalities tailored to specific applications, which makes thorough research essential.

In this blog, we will explore the essential factors to consider when selecting a Chemical Dosing Pump, discuss the various alternatives available, and provide insights that will help you make an informed decision to enhance your processes while optimizing costs and performance.

When selecting a chemical dosing pump, it's crucial to consider a few key factors to ensure you choose the best pump for your specific needs. First, evaluate the viscosity and chemical properties of the substances you'll be dosing. Different pumps are designed to handle varying levels of viscosity and corrosive materials, so understanding the characteristics of the chemicals involved is essential.

Another important factor is the flow rate requirement. Determine the volume of chemical you need to dose over a specific period, as this will help narrow down your options significantly. Additionally, consider whether you need a fixed or variable flow rate, as some applications may require flexibility in dosing.

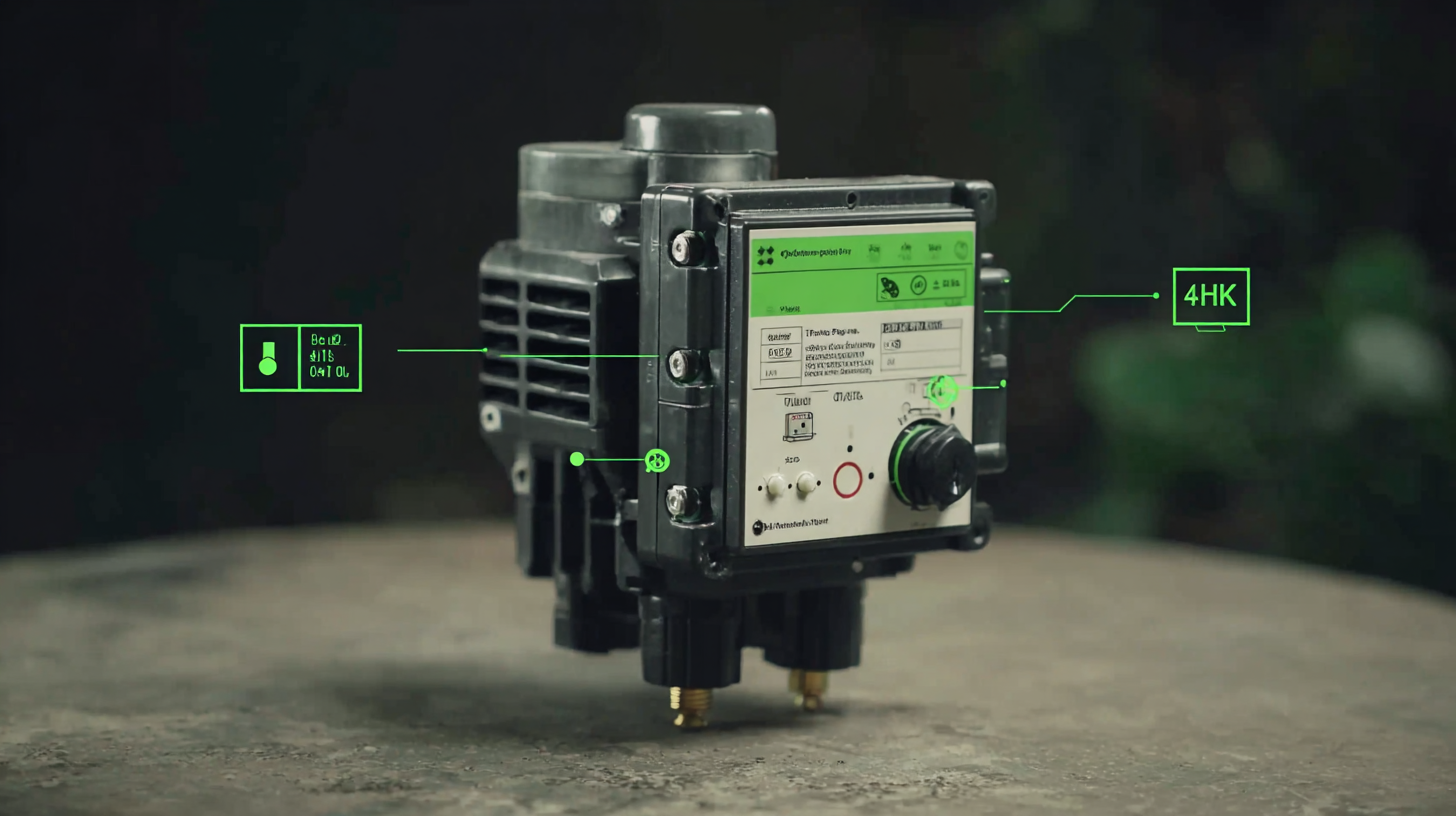

Tips: Always analyze the compatibility of the pump materials with the chemicals to prevent any reactions that could compromise performance. Additionally, consider the installation and maintenance requirements of the pump since ease of use can significantly impact your operational efficiency. Lastly, ensure that the pump has a reliable control system, which can enhance precision in dosing and overall system performance.

Emerging technologies are poised to transform the chemical dosing pump industry by 2025, especially as industries increasingly emphasize precision and efficiency. According to a recent market research report, the global chemical dosing pump market is expected to reach $5.8 billion by 2025, growing at a CAGR of 5.7% from 2020. This growth is driven by advancements in automation, IoT integration, and smart dosing solutions that allow for real-time monitoring and adjustments, significantly enhancing operational efficiency.

As industries, particularly water treatment, pharmaceuticals, and food and beverage, adopt these emerging technologies, the demand for advanced chemical dosing pumps is set to surge. The integration of artificial intelligence and machine learning will enable predictive maintenance and accurate dosing, ultimately reducing chemical waste and lowering operational costs. Moreover, the increasing focus on sustainability and regulatory compliance will push manufacturers to develop pumps that not only perform efficiently but also minimize environmental impact. With these advancements, the landscape of chemical dosing pumps will change dramatically, ensuring they meet the specific needs of diverse applications.

When selecting a chemical dosing pump, it’s essential to consider not just the pump’s specifications but also alternative solutions that could better suit your specific applications. While traditional dosing pumps are commonly used for precise chemical injection, emerging technologies and pump designs can provide enhanced efficiency and functionality. For instance, peristaltic pumps are excellent for applications requiring gentle handling of shear-sensitive fluids, while diaphragm pumps can efficiently manage a wide range of viscosities and pressures.

Exploring alternative pumping solutions can also lead to significant cost savings and improved environmental sustainability. Options such as magnetic drive pumps eliminate potential leakage issues, providing a safer choice for hazardous or corrosive chemicals. Additionally, advancements in smart pumping systems enable real-time monitoring and automated adjustments, allowing for optimal dosing accuracy and minimizing waste. By evaluating these diverse alternatives, businesses can tailor their pumping solutions to meet the unique challenges of their operations, ensuring both reliability and performance in their chemical management processes.

When it comes to selecting a chemical dosing pump, maximizing efficiency and reliability is paramount. A well-chosen pump not only enhances the accuracy of chemical delivery but also boosts the overall performance of the dosing system. To begin, understanding the specific requirements of your application is crucial.

Factors such as flow rate, pressure, and chemical compatibility should guide your selection process. Opt for pumps that feature adjustable flow rates and precise control mechanisms, as these will allow for fine-tuning in various operational conditions, ensuring that the right amount of chemicals is dosed consistently.

Reliability in chemical dosing systems hinges on the durability and maintenance needs of the pump. Choosing a pump made from high-quality materials resistant to corrosion and wear can significantly reduce downtime and maintenance costs.

Additionally, incorporating diagnostic features such as flow monitoring and pressure sensors can help in early detection of issues, thus enhancing system reliability. Investing in a reliable dosing pump means not only achieving operational efficiency but also ensuring safety and compliance with regulatory standards, ultimately leading to a more sustainable operation.

When selecting the best chemical dosing pump for specific applications, it's essential to consider the various types available on the market. The most common types include diaphragm pumps, peristaltic pumps, solenoid pumps, plunger pumps, and hydraulic pumps. Each type has unique characteristics that cater to different industrial needs. For instance, diaphragm pumps are known for their reliability and precision in handling corrosive fluids, while peristaltic pumps excel in maintaining clean fluid paths due to their design, making them ideal for sanitary applications.

In addition to pump types, understanding the comparative advantages of popular brands and models can significantly impact your decision. Different manufacturers offer distinct features, such as varying control mechanisms, flow rates, and ease of maintenance. By conducting a thorough analysis of these parameters, users can identify the most suitable dosing pump that aligns with their operational requirements and budget constraints. Consideration of both technical specifications and brand reputation will ensure that the chosen pump effectively meets the demands of the intended chemical dosing application.

This chart provides a comparative analysis of various chemical dosing pump specifications, focusing on flow rate, maximum pressure, and accuracy. The data represents three common types of dosing pumps suitable for different applications.

Copyright © 2023 TUF Pump Industry (Jiangsu) Co., Ltd. - Stainless Steel Centrifugal Pump, Chemical Pump, Metering Pump - All Rights Reserved.