Blog

- Home

- Blog

How to Choose the Right Solenoid Metering Pump for Your Needs?

Choosing the right solenoid metering pump can be daunting. Many factors come into play. These pumps are critical in various industries, from chemical processing to water treatment.

A solenoid metering pump delivers precise amounts of liquid. Their applications range from agriculture to manufacturing. You must consider flow rate, pressure, and fluid compatibility. These specifications can vary widely among different models.

Often, users overlook pump maintenance requirements. Regular upkeep can prevent costly downtimes. Additionally, the installation process may pose challenges. Not every pump is user-friendly. Take time to research each option thoroughly. This will help ensure you make the right choice for your specific needs.

Understanding the Basics of Solenoid Metering Pumps

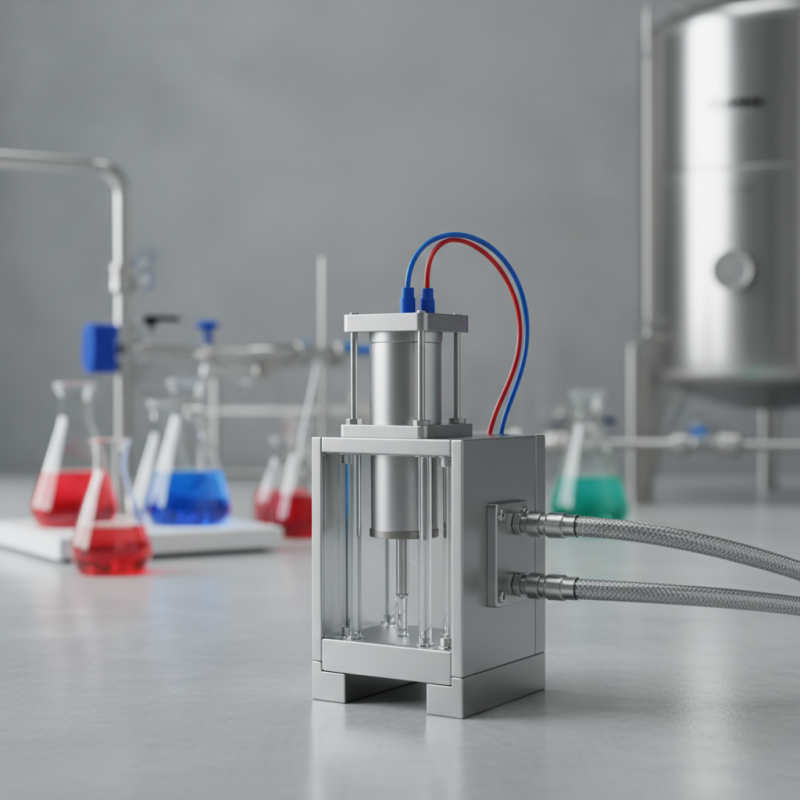

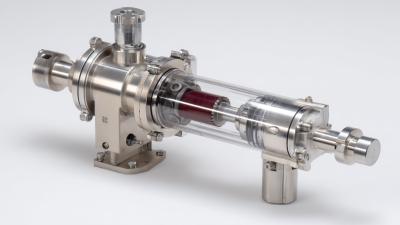

Understanding the basics of solenoid metering pumps is essential for effective fluid handling. These pumps are designed to dispense precise amounts of liquids. They operate using an electromagnetic solenoid. When activated, the solenoid pushes a diaphragm back and forth. This action creates a vacuum that draws in fluid, then pushes it out.

These pumps come in various models, each suited for different applications. Flow rates can vary from a few milliliters to several liters per hour. Users must consider the chemical properties of the fluid being pumped. Compatibility is crucial. Corrosive liquids may require special materials. Regular maintenance is needed to ensure accuracy. Users might overlook the importance of routine checks.

Noise can also be an issue. Some pumps can be quite loud during operation. This may require users to find soundproofing solutions. Identifying the right solenoid metering pump can seem daunting. Users have different needs and limitations. Understanding your requirements is key. A little research can make a big difference in performance.

How to Choose the Right Solenoid Metering Pump for Your Needs?

This bar chart illustrates the comparison of various solenoid metering pump specifications based on flow rate and pressure. It helps in understanding which pump might be suitable for different applications based on capacity needs.

Identifying Your Application Requirements and Specifications

Choosing the right solenoid metering pump requires a clear understanding of your application requirements. Consider factors like flow rate, pressure, and fluid compatibility. It’s essential to match the pump's specifications with your process demands. For instance, if your application needs a flow rate of 1 to 30 liters per hour, choose a pump that meets or exceeds this range.

Fluid properties also play a crucial role. Different fluids can affect the performance of the pump. For example, viscous or corrosive liquids may demand specialized pump materials. A report from the Fluid Handling Association indicates that 45% of pump failures result from incompatibility with the fluid. This is a significant statistic that highlights the importance of proper selection.

Don't overlook installation conditions. The surrounding environment can impact pump efficiency. High temperatures or vibrations might lead to premature failure. Industry data shows that 30% of installations fail due to inadequate environmental considerations. Address these elements early to avoid costly mistakes. Choosing the right pump isn't just technical; it demands reflection on all aspects of your application.

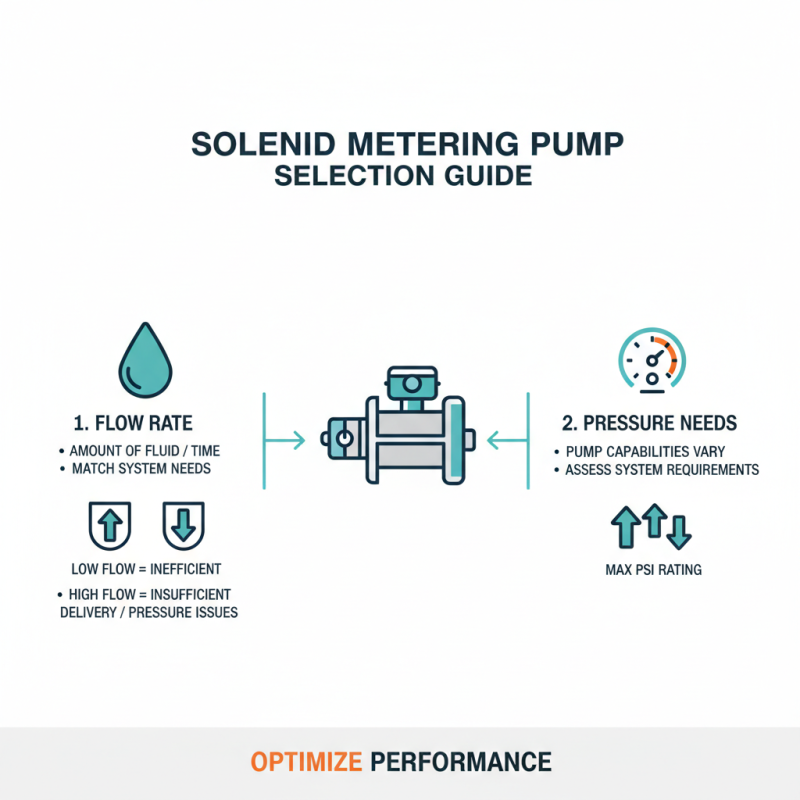

Evaluating Flow Rate and Pressure Needs for Your System

When selecting a solenoid metering pump, understanding flow rate and pressure needs is critical. Flow rate decides how much fluid is delivered over time. Pumping capabilities vary widely among different models. Assessing your system’s requirements is essential. Too low a flow rate can lead to inefficiency. Conversely, too high a rate can create pressure issues.

Consider the specific application. Is it for a chemical process, or perhaps water treatment? Each application demands different flow and pressure specifications. Knowing the viscosity and density of the fluid can also guide your choice. A pump may work well in one scenario but falter in another.

Measure your system's pressure needs precisely. Too much pressure can damage equipment. Too little can result in underperformance. Often, people overlook the importance of pressure ratings. Misjudgments can cause setbacks or costly repairs. It’s essential to evaluate these factors thoroughly. Take your time when deciding. A rush could lead to a mismatched pump and system.

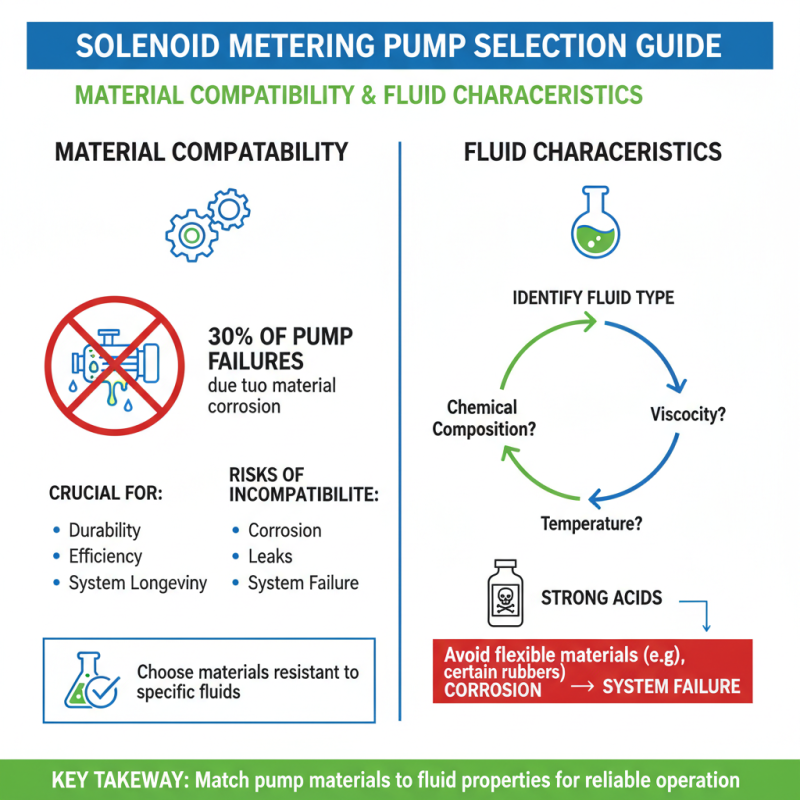

Considering Material Compatibility and Fluid Characteristics

Choosing the right solenoid metering pump involves understanding material compatibility and fluid characteristics. Material compatibility is crucial to ensure durability and efficiency. According to industry reports, nearly 30% of pump failures are due to material corrosion. Selecting materials that resist the specific fluids you are handling is essential. For example, other flexible materials might corrode when exposed to strong acids, leading to system failures.

Fluid characteristics also play a significant role. Viscosity, density, and temperature can all affect pump performance. A study found that over 40% of users fail to account for fluid viscosity, which can lead to inaccurate dosing. The pump's diaphragm, for instance, should be made from materials suited for the fluid being pumped. Using inappropriate materials can lead to leaks and contamination.

Another factor to consider is operating pressure. Many solenoid pumps operate optimally within specific pressure ranges. Operating outside these limits can result in inefficiencies. Industry data suggests up to 25% of users inadvertently exceed these ranges. Understanding these aspects, while often overlooked, is necessary for ensuring a reliable and effective pumping solution.

Assessing Maintenance and Operational Costs of Your Pump

When selecting a solenoid metering pump, understanding maintenance costs is crucial. Maintenance can vary based on the pump's design and usage. Regular inspections are necessary to ensure optimal operation. Neglecting these checks may lead to unexpected breakdowns. Parts like seals and diaphragms may wear out. Frequent replacement can quickly raise costs.

Operational costs also play a significant role in decision-making. Energy consumption is a key factor. Some pumps consume more power, affecting your overall budget. Additionally, consider the fluid being pumped. Chemicals may necessitate specialized materials, increasing expenses. If the pump operates in harsh conditions, it may need more frequent servicing.

Reflecting on these aspects can help you avoid hidden costs. Ignoring maintenance can lead to downtime and loss of productivity. Choosing a pump based on initial price alone may backfire. A comprehensive understanding of maintenance and operational costs will aid in making an informed decision.

How to Choose the Right Solenoid Metering Pump for Your Needs? - Assessing Maintenance and Operational Costs of Your Pump

| Pump Type | Flow Rate (L/hr) | Max Pressure (bar) | Power Consumption (W) | Maintenance Frequency (months) | Approx. Annual Cost ($) |

|---|---|---|---|---|---|

| Type A | 50 | 10 | 200 | 6 | 1200 |

| Type B | 75 | 12 | 250 | 8 | 1500 |

| Type C | 100 | 15 | 300 | 12 | 1800 |

| Type D | 125 | 18 | 350 | 10 | 2200 |

| Type E | 150 | 20 | 400 | 14 | 2500 |

Related Posts

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications

-

What Makes Plunger Metering Pump Essential for Precision Fluid Control

-

Exploring the Impact of Diaphragm Metering Pumps at the 138th China Import and Export Fair 2025

-

Understanding the Efficiency and Applications of Plunger Metering Pumps in Industrial Settings

-

Top 10 Industrial Metering Pumps: Key Features, Market Trends, and User Insights for 2023

-

How to Select and Maintain a Plunger Metering Pump for Optimal Performance