Blog

- Home

- Blog

How to Choose the Right Plunger Pump for Your Industrial Needs

Choosing the right plunger pump for industrial applications is a critical decision that can significantly impact efficiency, reliability, and overall operational success. With a myriad of options available in today’s marketplace, understanding the specific requirements of your operations is vital. Plunger pumps are renowned for their ability to handle high pressures and viscous fluids, making them an ideal choice for industries ranging from chemical processing to oil and gas.

When selecting a plunger pump, key factors such as flow rate, pressure rating, and material compatibility should be thoroughly evaluated. It is essential to match the pump's specifications with the particular demands of your application to ensure optimal performance and longevity. Additionally, understanding the various types of plunger pumps—each designed for specific purposes—can help you make an informed decision that aligns with your operational goals.

In this article, we will explore the top digital types of plunger pumps, discussing their features, advantages, and best-use scenarios. By the end, you will be equipped with the knowledge to confidently choose the right plunger pump tailored to your industrial needs, ultimately enhancing your operational efficiency and productivity.

Key Considerations for Selecting an Industrial Plunger Pump

When selecting the right plunger pump for your industrial needs, several key considerations come into play. First, it's essential to evaluate the fluid characteristics, including viscosity, temperature, and potential corrosiveness. Understanding these parameters will help you choose a pump that can handle the specific requirements of the application without compromising performance or durability.

Another critical aspect to consider is the operational environment. Factors such as the availability of space, the pump's required maintenance frequency, and potential exposure to harsh conditions can significantly influence your choice. For instance, enclosed or submersible pumps may be necessary for challenging environments, while a traditional plunger pump might suffice for less demanding applications.

Types of Plunger Pumps and Their Applications in Different Industries

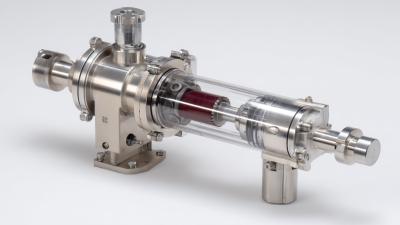

When selecting a plunger pump for industrial applications, understanding the different types available and their specific uses is crucial. The most common varieties include hydraulic plunger pumps, pneumatic plunger pumps, and electric plunger pumps. Hydraulic plunger pumps are ideal for high-pressure applications where precise fluid delivery is necessary, making them suitable for industries like oil and gas or chemical processing. Their ability to handle aggressive fluids enhances their usage in environments where other pumps may fail.

Pneumatic plunger pumps, powered by compressed air, excel in environments with explosive materials or where electricity poses risks. These pumps are frequently used in the pharmaceuticals and food processing industries due to their sanitary designs and ability to prevent contamination. Electric plunger pumps, on the other hand, are preferred for standard fluid transport due to their efficiency and lower operational costs. They are widely utilized in water treatment plants, manufacturing facilities, and various industrial sectors requiring consistent flow rates. Choosing the right type based on the application can drastically improve operational efficiency and ensure safety in industrial processes.

Plunger Pump Types and Their Industrial Applications

Factors Affecting the Performance of Plunger Pumps

When selecting a plunger pump for industrial applications, understanding the factors that affect its performance is crucial. One primary consideration is the viscosity of the fluid being pumped. High-viscosity fluids may require a pump with greater power and a robust design to maintain efficiency, whereas low-viscosity fluids can be handled by less powerful models. Another important aspect is the operating pressure and flow rate. The pump must be capable of handling the specific pressure and flow requirements of the system to ensure optimal performance and longevity.

Additionally, the material compatibility with the fluid is essential. Different fluids can be corrosive or abrasive, which may dictate the construction materials of the pump components. This impact on durability and maintenance needs cannot be overstated. Moreover, the pumping environment, including temperature fluctuations and exposure to chemicals, also plays a significant role in choosing the appropriate plunger pump. By carefully evaluating these factors, industries can select the most efficient and reliable plunger pump tailored to their operational requirements.

Maintenance Tips for Prolonging the Life of Your Plunger Pump

When it comes to maintaining the longevity and performance of plunger pumps, a proactive approach is essential. Regular maintenance can significantly extend the operational life of these pumps, which are critical in various industrial applications. According to industry reports, neglecting routine checks can lead to performance drops of up to 30%, emphasizing the importance of consistent upkeep.

One of the most common issues plunger pumps face is associated with their components: the pump head, hoses, and seals. Monitoring these elements can prevent minor wear and tear from escalating into major failures. For instance, ensuring that the air hose is free from obstructions and that the seal remains intact can keep the pump running smoothly. Additionally, drivers are advised to relieve pressure from the pump when it’s not in use, which can prevent unnecessary strain on the components. Such practices not only maintain functionality but also significantly reduce costly downtime and repairs.

Furthermore, incorporating a routine inspection schedule that includes checking the pressure gauge and cleaning any debris from the pump can lead to early detection of issues, resulting in more effective and economical maintenance strategies. Industry studies suggest that companies that implement regular maintenance protocols reduce repair costs by an average of 20%. By prioritizing these practices, businesses can ensure that their plunger pumps operate efficiently and have a prolonged service life.

Cost Analysis: Balancing Quality and Budget for Plunger Pumps

When selecting a plunger pump for industrial applications,

cost analysis plays a crucial role in striking a balance between

quality and budget.

It's essential to begin by assessing the specific requirements of your operation,

including flow rates, pressure needs, and the type of fluids being handled.

Investing in high-quality plunger pumps often results in enhanced durability and performance,

leading to lower maintenance costs over time.

However, it's equally vital to avoid overspending on features that may not be necessary

for your specific application.

To navigate this balance effectively, businesses should conduct a thorough comparison

of various pump models and their price points. Evaluating the total cost of ownership,

which includes initial purchase price, maintenance expenses, and potential downtimes,

can provide insight into long-term financial impacts.

Furthermore, it can be beneficial to explore options for refurbished

or alternative brands that offer competitive pricing without compromising on quality.

By carefully weighing these factors, companies can make informed decisions that align

with their operational needs and financial constraints.

Related Posts

-

Innovative Solutions for Plunger Metering Pump Applications

-

Understanding the Importance of Water Metering for Sustainable Water Management

-

5 Innovative Ways Pressure Pumps Enhance Industrial Efficiency

-

Understanding the Efficiency and Applications of Plunger Metering Pumps in Industrial Settings

-

Top 7 Expert Tips for Using High Pressure Diaphragm Pumps Effectively

-

Understanding the Importance of High Pressure Dosing Pumps in Modern Industries