Blog

- Home

- Blog

2025 How to Choose the Right Chemical Pumps for Your Industry Needs

In the ever-evolving landscape of industrial operations, selecting the appropriate chemical pumps is crucial for ensuring both efficiency and safety. As industry expert Dr. Emily Lawson, a leading authority in fluid dynamics, aptly states, "The right chemical pump can significantly enhance operational effectiveness and prolong the lifespan of systems." With the diverse range of chemicals processed across various sectors, understanding the unique requirements of your industry becomes paramount in making informed decisions.

The selection process for chemical pumps involves careful consideration of factors such as fluid characteristics, flow rates, and pressure requirements. As industries increasingly strive for sustainability and cost-effectiveness, the importance of choosing the right pump cannot be understated. Not only does the right pump ensure smooth operations, but it also plays a vital role in minimizing environmental impact and reducing downtime.

As we delve into the intricacies of selecting the best chemical pumps for your industrial needs, we will explore key considerations and expert insights that will guide you towards making the best choice for your operations in 2025 and beyond. Whether you are in manufacturing, pharmaceuticals, or wastewater treatment, understanding the significance of chemical pumps will empower you to optimize your processes and achieve your operational goals.

Understanding the Basics of Chemical Pumps and Their Applications

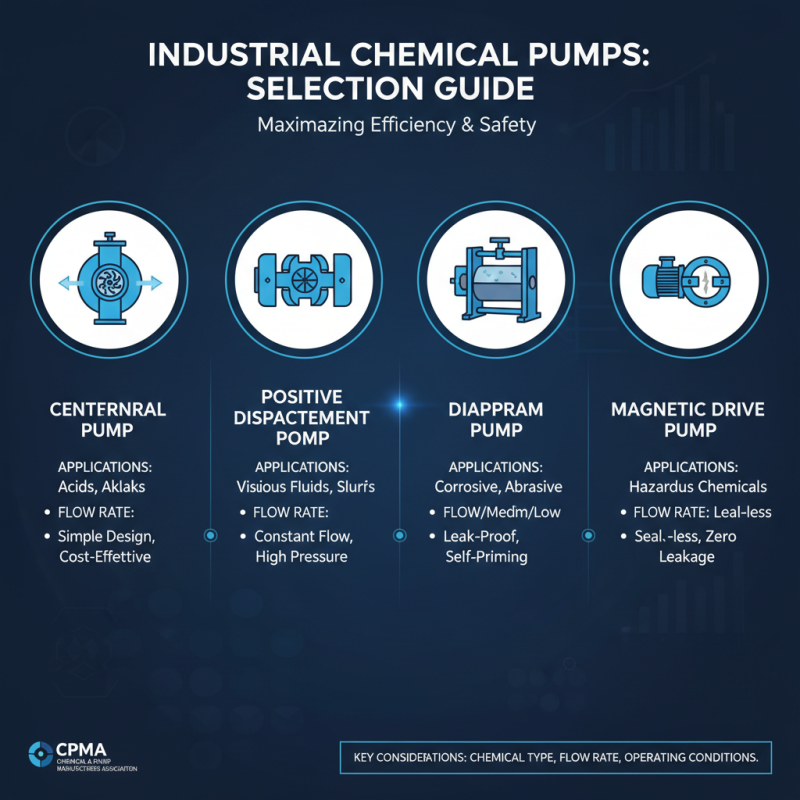

When selecting the right chemical pump for specific industrial needs, it is crucial to first understand the fundamental types and their applications. Chemical pumps are designed to handle various fluids, including corrosive, viscous, or abrasive substances. The choice often depends on the fluid’s properties, such as viscosity, temperature, and chemical compatibility. For instance, centrifugal pumps are widely used in applications where high flow rates are required, while positive displacement pumps are ideal for moving thick or viscous materials at controlled rates.

In addition to fluid characteristics, it is important to consider the operating environment and the pump’s capacity to withstand specific conditions. Factors such as pressure limits, potential for leakage, and maintenance requirements also play a vital role in the selection process. Understanding the installation space and any regulatory compliance needed for the operation can further guide the decision. By accurately assessing these elements, industries can ensure they select a chemical pump that meets their operational demands efficiently and safely.

2025 How to Choose the Right Chemical Pumps for Your Industry Needs

| Pump Type | Material Compatibility | Max Flow Rate (GPH) | Pressure Rating (PSI) | Application |

|---|---|---|---|---|

| Diaphragm Pump | Acids, Bases | 50 | 100 | Chemical Transfer |

| Centrifugal Pump | Water, Mild Chemicals | 200 | 50 | Cooling Systems |

| Gear Pump | Oils, Viscous Fluids | 100 | 150 | Hydraulic Systems |

| Peristaltic Pump | Slurries, Corrosive Liquids | 30 | 75 | Laboratory Applications |

| Submersible Pump | Wastewater, Sewage | 500 | 30 | Sewage Systems |

Key Considerations for Selecting Chemical Pumps in Various Industries

When choosing the right chemical pumps for your industry needs, it's essential to consider several crucial factors tailored to the specific requirements of your sector. According to a report by the Chemical & Pump Manufacturers Association (CPMA), the global chemical pump market is projected to reach $5.5 billion by 2025, underscoring the importance of selecting pumps that maximize efficiency and safety in your operations. Key considerations include the type of chemicals being handled, the required flow rate, and the ambient operating conditions.

One important tip is to assess the chemical compatibility of pump materials with the substances being pumped. The wrong choice can lead to pump failure or hazardous leaks, which could endanger workers and the environment. Additionally, the pump's operational efficiency plays a significant role in overall cost-effectiveness. A study published in the Journal of Chemical Engineering highlighted that properly sized and selected pumps can reduce energy consumption by up to 30%, showcasing the need for careful evaluation.

Also, consider the maintenance requirements and lifecycle costs of pumps. Investing in a pump with lower maintenance needs can significantly ease operational burdens. According to data from the International Association of Plumbing and Mechanical Officials (IAPMO), organizations can achieve up to a 25% reduction in downtime by selecting pumps with robust engineering and user-friendly maintenance features. By prioritizing these considerations, industries can optimize their chemical handling processes effectively.

Types of Chemical Pumps and Their Specific Advantages

When selecting the right chemical pumps for various industrial applications, understanding the different types of chemical pumps and their specific advantages is crucial. Centrifugal pumps are widely used due to their efficiency and ability to handle large volumes of fluids. They operate by converting rotational kinetic energy to hydrodynamic energy, making them ideal for applications requiring continuous flow. Their design allows for easy maintenance and operation, which is advantageous in industries where uptime is critical.

Another popular category is positive displacement pumps, which include diaphragm and gear pumps. These pumps function by trapping a fixed amount of fluid and forcing it through the discharge. Their precision makes them suitable for applications that require accurate flow rates and pressures, such as in chemical processing and laboratory settings. Diaphragm pumps, in particular, are known for their ability to handle corrosive and abrasive materials, ensuring reliability and safety in handling hazardous substances. Understanding these pump types and their unique benefits will aid industries in making informed decisions tailored to their specific operational needs.

2025: How to Choose the Right Chemical Pumps for Your Industry Needs

Evaluating Pump Performance Metrics for Optimal Efficiency

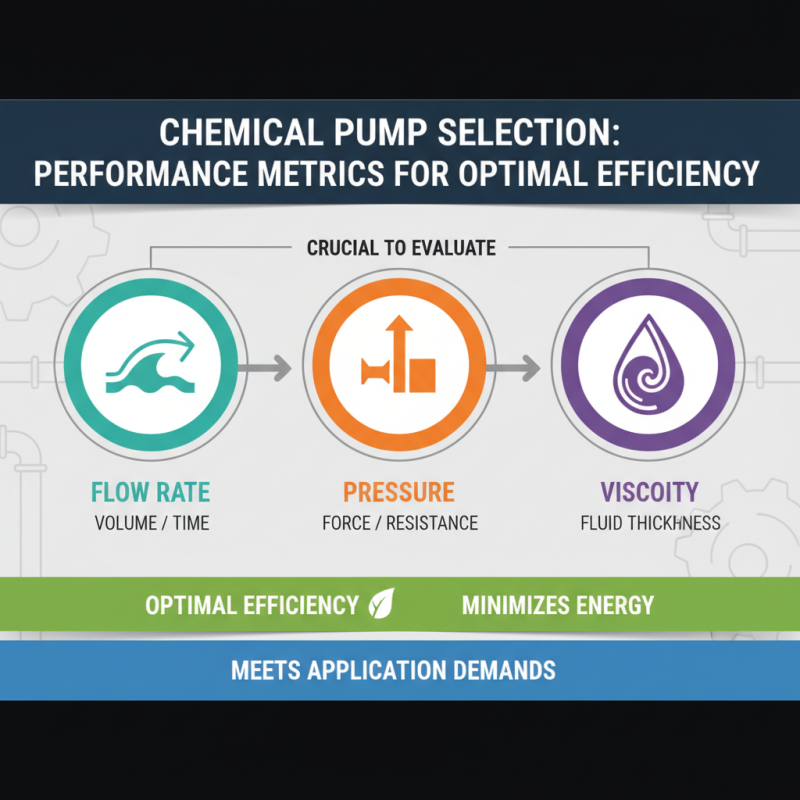

When selecting the right chemical pumps for industrial applications, evaluating performance metrics is crucial for achieving optimal efficiency. Key metrics such as flow rate, pressure, and viscosity must be assessed to ensure the pump meets the specific demands of the application. Flow rate determines the volume of fluid the pump can deliver over a set period, while pressure indicates the ability of the pump to move fluids against resistance. Understanding these factors can help in selecting a pump that not only meets operational efficiency but also minimizes energy consumption.

In addition to flow rate and pressure, the pump's efficiency and durability play significant roles in performance assessment. The efficiency of a pump is influenced by its design and the materials used in construction, impacting both operational costs and maintenance requirements. Also, considering the expected lifespan and potential wear and tear can guide the selection process, ensuring that the chosen pump can handle the intended workload over time. By focusing on these metrics, industries can enhance productivity and reduce downtime, paving the way for more sustainable operations.

Maintenance and Troubleshooting Tips for Chemical Pumps

When it comes to maintaining chemical pumps, understanding common issues and their solutions is essential for ensuring operational efficiency. According to a study published by the Hydraulic Institute, approximately 15% of pump failures are attributed to improper maintenance practices. Regular inspections can significantly reduce downtime and enhance the lifespan of chemical pumps. Key maintenance practices include monitoring seals and bearings, regularly checking for leaks, and ensuring that the pump is operating at its optimal temperature and pressure.

Troubleshooting is another vital aspect of chemical pump maintenance. The American Society of Mechanical Engineers highlights that 60% of pump performance issues stem from cavitation, which can occur when the pump operates below its designed flow rates. Identifying symptoms such as unusual vibrations, noise, or fluctuations in pressure can help in early detection of issues. For example, implementing vibration analysis can pinpoint potential problems before they escalate. Regularly scheduled maintenance, combined with effective troubleshooting techniques, can lead to improved pump reliability and lower operational costs, with some reports suggesting savings of up to 30% in maintenance expenses when a proactive approach is adopted.

Related Posts

-

7 Best Industrial Pumps You Should Consider for Your Next Project

-

5 Best Chemical Pumps for Efficient Industrial Use

-

Ultimate Guide to Selecting the Right Industrial Dosing Pump for Your Needs

-

How to Choose the Best Chemical Pumps for Your Industrial Needs

-

Top 10 Industrial Pumps You Need to Know for Optimal Performance

-

Innovative Solutions for Plunger Metering Pump Applications