Blog

- Home

- Blog

Why Choose a Plunger Pump for Your Application Needs?

When selecting a pump for specific applications, the Plunger Pump stands out. John Smith, a renowned expert in the pumping industry, emphasizes, “Plunger Pumps offer reliability and efficiency for demanding tasks.” This unique design is ideal for high-pressure processes across various sectors.

Plunger Pumps operate by using a piston to generate pressure. This mechanism allows for precise fluid handling. Industries often face challenges with other pump types. For example, centrifugal pumps may struggle with viscosity or pressure requirements. Plunger Pumps can meet those needs.

However, there are considerations. While Plunger Pumps are robust, they require regular maintenance. Proper care is essential to prevent wear and ensure efficiency. Transitioning from traditional pumps might be daunting. Understanding the benefits and drawbacks is crucial for informed decisions. Reflecting on these aspects can lead to greater efficiency and durability in your operations.

Benefits of Using Plunger Pumps in Various Industries

Plunger pumps are gaining traction across various industries. Their design allows for efficient handling of viscous fluids. This feature is crucial for the oil and gas sector, where pumping thick crude oil is common. According to industry reports, plunger pumps can maintain high pressure while minimizing wear and tear. This results in a longer lifespan and reduced maintenance costs.

In the food and beverage sector, precision is vital. Plunger pumps ensure accurate metering of ingredients. They help maintain product consistency, which can improve customer satisfaction. The ability to handle different viscosities is another advantage. This flexibility makes them popular for juices, sauces, and even dairy products. A study indicates that industries adopting plunger pumps see up to a 25% increase in efficiency.

Tips: When selecting a plunger pump, consider the fluid's viscosity. Matching the pump type with your application's needs is essential. Regular maintenance can avoid unexpected repairs. Keep an eye on pressure levels. Monitoring pressures can signal when to service the pump.

Though effective, plunger pumps need proper care. Operators sometimes overlook routine check-ups. This can lead to performance issues. It's important to establish a maintenance schedule to ensure optimal operation. Inconsistent maintenance can lead to more significant problems in the long run.

Understanding the Mechanism of Plunger Pumps

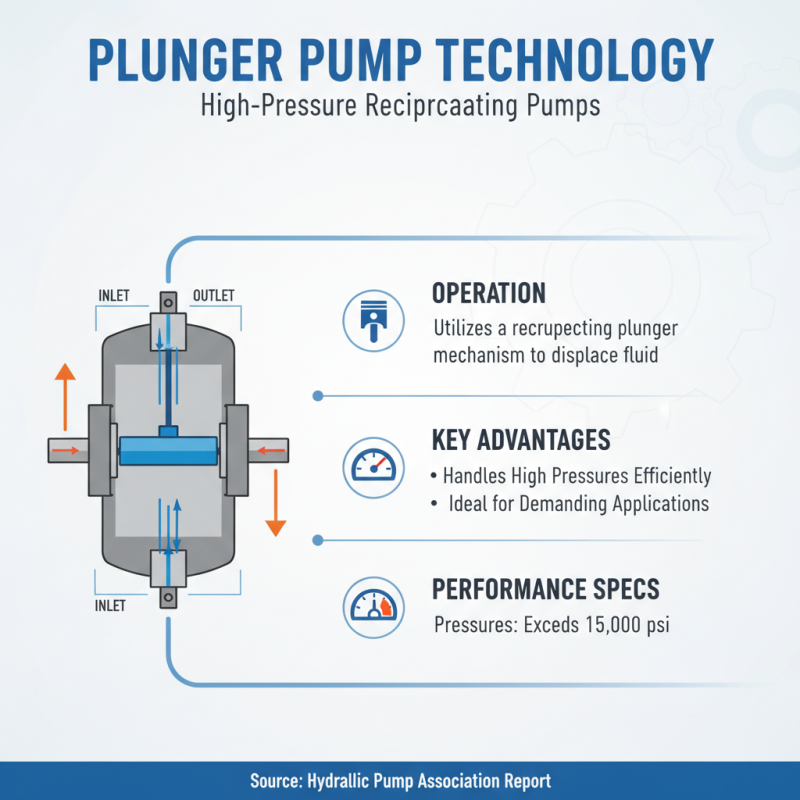

Plunger pumps are unique in their design and functionality. They can handle high pressure and deliver precise flow rates. Understanding their mechanism enhances your application choices. Essential components include the plunger, cylinder, and valves. As the plunger moves back, it creates suction, drawing fluid in. When pushed forward, it generates pressure, expelling the fluid smoothly.

In many industrial applications, efficiency matters. A well-calibrated plunger pump can minimize energy consumption. This leads to cost savings over time. Maintenance is vital too. Regular checks ensure that seals and valves function correctly. Neglecting these can lead to poor performance or failure.

**Tip:** Always monitor fluid viscosity. It impacts pump efficiency. Too thick, and you risk damaging components. Choose your materials wisely to avoid wear. Consider the environment where the pump operates. Doing so can extend its life significantly.

Why Choose a Plunger Pump for Your Application Needs? - Understanding the Mechanism of Plunger Pumps

| Feature | Description | Advantages | Applications |

|---|---|---|---|

| Operating Principle | Uses a piston to generate flow, moving fluid through a valve. | High efficiency, consistent flow rate. | Water treatment, chemicals, food processing. |

| Pressure Range | Capable of handling high pressures up to thousands of psi. | Suitable for demanding applications requiring high pressure. | Oil and gas extraction, hydraulic systems. |

| Fluid Types | Can handle viscous fluids, slurries, and particulates. | Versatile for various fluid properties. | Mining, agricultural chemical application. |

| Maintenance | Requires regular maintenance but generally low wear. | Long service life with proper care. | Industrial applications, wastewater management. |

| Energy Efficiency | Designed to minimize energy consumption. | Cost-effective operation. | General manufacturing, construction. |

Comparison of Plunger Pumps with Other Pump Types

Plunger pumps are distinct in their operation, especially when compared to other pump types like centrifugal and diaphragm pumps. These pumps use a reciprocating mechanism, which allows them to handle high pressures efficiently. According to a recent report by the Hydraulic Pump Association, plunger pumps can operate at pressures exceeding 15,000 psi, making them ideal for demanding applications.

In contrast, centrifugal pumps often struggle with high viscosity fluids. They rely on fluid dynamics to create pressure, which can be less effective in certain conditions. A study by the American Society of Mechanical Engineers noted that while centrifugal pumps can move large volumes of liquid, they may not perform well when dealing with thicker materials. Plunger pumps, with their positive displacement capabilities, excel where others falter.

However, choosing a plunger pump isn't always straightforward. Maintenance can be more complex compared to simpler designs. They're prone to wear in certain environments, especially with abrasive fluids. Understanding these nuances is crucial. Users need to assess their specific application conditions carefully. Balancing the pros and cons requires reflection and often leads to tough decisions.

Common Applications of Plunger Pumps in Real-World Scenarios

Plunger pumps are versatile devices found in various industries. They excel in high-pressure applications. For instance, in oil and gas extraction, they facilitate the movement of thick fluids. This is crucial because viscosity can hinder flow. Operators often face challenges in maintaining consistent pressure. Yet, plunger pumps offer reliability despite these hurdles.

In the food processing industry, these pumps transfer liquids efficiently. They handle everything from juices to sauces. The need for hygiene makes these pumps essential. However, manufacturers must constantly monitor for contamination risks. A single lapse could compromise the entire batch. This highlights the importance of thorough inspections.

Hydraulic systems also benefit from plunger pumps. They enable precise control over machinery. This is vital in manufacturing settings, where accuracy is key. However, operators sometimes report inconsistent performance. Regular maintenance is necessary to avoid issues. Plunger pumps can still fail due to wear and tear. These realities remind users that even reliable systems require attention.

Common Applications of Plunger Pumps

Factors to Consider When Selecting a Plunger Pump

When selecting a plunger pump, several factors should be considered carefully. The application type is crucial. Understand the fluids being pumped. Are they viscous or abrasive? The pump material must match the fluid characteristics. This prevents damage or contamination over time.

Performance specifications play a vital role too. Pressure requirements can vary greatly across applications. Ensure the pump can handle the necessary pressure without strain. Remember, exceeding limits can lead to premature failure.

Tips: Choose a pump with an adjustable stroke length. This adds flexibility to your operation. Additionally, think about maintenance needs. Less maintenance usually means lower downtime.

Bear in mind that not all pumps are alike. Sometimes, specific conditions can make one pump less effective. Evaluating the total cost of ownership is essential. An initially cheaper pump could lead to higher costs in the long run. Adjust your choices based on real-case scenarios and feedback.

Related Posts

-

How to Choose the Right Plunger Pump for Your Industrial Needs

-

Essential Tips for Choosing the Right Plunger Pump for Your Needs

-

How to Choose the Right High Pressure Pump for Your Industrial Needs

-

How to Choose the Right High Flow Hydraulic Pump for Your Project

-

How to Optimize Pump Water Efficiency for Sustainable Resource Management

-

What Makes Plunger Metering Pump Essential for Precision Fluid Control