Blog

- Home

- Blog

How to Choose the Right High Pressure Chemical Pump for Your Application

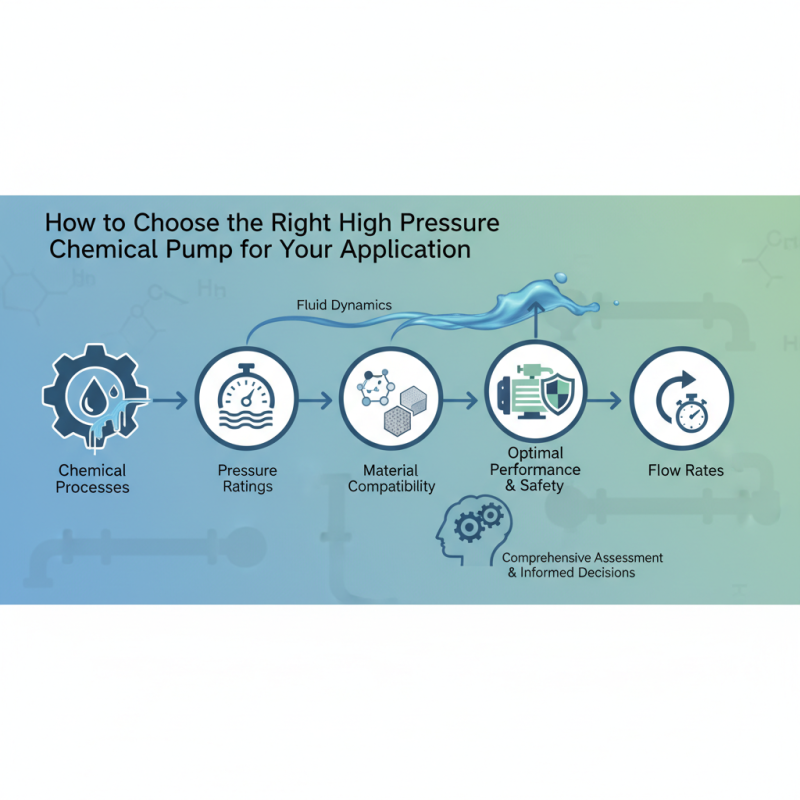

Choosing the right high pressure chemical pump for your specific application is a critical decision that can significantly influence the efficiency and safety of your operations. As noted by industry expert Dr. John Williamson, a leading authority in fluid dynamics, “Selecting the appropriate high pressure chemical pump is not merely a matter of performance; it involves understanding the unique requirements of your chemical processes and the environmental conditions in which they operate.” This underscores the importance of a comprehensive assessment when evaluating pump options.

In today's diverse and demanding industrial landscape, the right high pressure chemical pump can enhance productivity while minimizing risks associated with chemical handling. Factors such as pressure ratings, material compatibility, and flow rates must all be carefully considered to ensure optimal performance. By taking the time to analyze these aspects, businesses can make informed decisions that lead to sustained operational success. As we delve deeper into the criteria for selecting a high pressure chemical pump, it becomes clear that a methodical approach will yield the best results for any application, ultimately fostering innovation and safety in the chemical processing industry.

Understanding Your Fluid Characteristics and Requirements

When selecting a high-pressure chemical pump, understanding your fluid characteristics is crucial. The viscosity, temperature, and composition of the fluid will directly impact pump performance and longevity. For instance, high-viscosity fluids may require specialized impellers or motors to maintain efficiency and prevent overheating. Additionally, the chemical compatibility of the pump materials with the fluid must be assessed to avoid corrosion or material degradation over time.

Tips: Always conduct a thorough compatibility analysis between the pump materials and the chemicals being pumped to ensure durability. It's also advisable to consult with manufacturers or experts to gauge the appropriate pump type based on fluid behavior under different pressure and temperature conditions.

Furthermore, consider the flow rate and pressure requirements of your application. Calculating the total dynamic head and understanding system requirements are essential steps. Selecting a pump that can handle the desired flow rate while maintaining the necessary pressure can drastically affect operational efficiency and reliability.

Tips: Utilize online calculators or consult with engineering professionals to assess your specific flow and pressure needs accurately. Always account for potential fluctuations in these requirements to avoid future complications.

Assessing System Pressure and Flow Rate Needs

When selecting a high-pressure chemical pump for your application, understanding the system pressure and flow rate needs is paramount. The required pressure will depend on various factors, including the viscosity of the fluid, distance between the pump and its discharge point, and any elevation changes the fluid must overcome. According to industry reports, calculating these parameters accurately can lead to improvements in pump efficiency by up to 20%. Misestimating pressure requirements can result in significant performance issues, including reduced flow rates and increased operational costs.

Flow rate needs are equally critical to consider. Depending on your application, selecting the right flow rate ensures that your system operates smoothly and efficiently. For instance, a typical industrial setup often requires flow rates ranging from a few gallons per minute (GPM) to several hundred, depending on the specific process demands. Industry studies show that optimizing flow rates not only enhances productivity but also minimizes wear on pump components, extending their lifespan by an average of 15-30%.

**Tip:** When evaluating flow rates, consider conducting a pilot test to gather data on how your system performs under various conditions. This real-world information can provide invaluable insights for making accurate calculations.

**Tip:** Consult existing case studies to see how similar applications managed their pressure and flow rate needs effectively. Learning from these examples can help inform your choices and support your decision-making process.

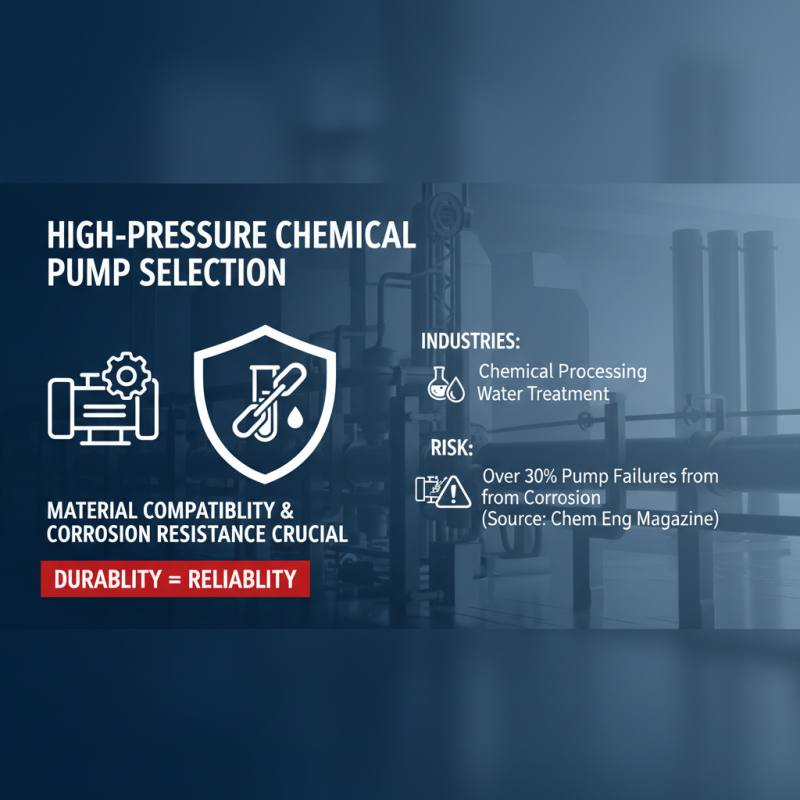

Evaluating Pump Material Compatibility and Corrosion Resistance

When selecting a high-pressure chemical pump, evaluating the material compatibility and corrosion resistance is paramount. Many industries, including chemical processing and water treatment, require pumps that can withstand aggressive fluids and high operational pressures. According to a report by the Chemical Engineering Magazine, over 30% of pump failures in industrial applications can be attributed to material degradation caused by corrosion. This highlights the necessity for careful consideration of the pump materials in relation to the intended application.

Material compatibility depends on several factors, including chemical composition, temperature, and pressure levels. For instance, stainless steel pumps are often preferred for their excellent corrosion resistance in various environments, but their suitability varies depending on the specific chemicals being handled. A study by the American Society of Mechanical Engineers (ASME) indicates that carbon steel can be effective for non-corrosive fluids, but is prone to rapid deterioration when exposed to acidic or alkaline substances. Thus, applying a corrosion-resistant coating or opting for advanced materials such as duplex stainless steel or nickel alloys can enhance the longevity and reliability of the pump system.

Furthermore, it's essential to conduct a thorough risk assessment to identify potential corrosive interactions. The National Association of Corrosion Engineers (NACE) has reported that a well-implemented corrosion management program can reduce maintenance costs by up to 25%. This involves not only selecting suitable pump materials but also considering factors such as design, environmental conditions, and the life cycle of the system. Proper material selection, grounded in a comprehensive analysis, ultimately leads to improved performance and reduced operational risks in high-pressure chemical applications.

Considering Pump Design Types and Their Advantages

When selecting a high pressure chemical pump, understanding the different pump design types and their advantages is crucial for optimizing performance and efficiency. Centrifugal pumps, for instance, are commonly used for their ability to handle large volumes of fluids at low to moderate pressures. Their simple design facilitates easy maintenance and operation, making them ideal for applications where continuous flow is required. On the other hand, positive displacement pumps are favored for high pressure applications because they deliver a consistent flow rate regardless of pressure changes in the system. This makes them particularly suitable for viscous fluids or applications that demand precise dosing.

Additionally, each pump design type has its own unique benefits that can influence the choice for specific applications. For example, diaphragm pumps are excellent for handling corrosive chemicals, as their design prevents fluid from coming into contact with moving parts, thus providing superior protection. Meanwhile, screw pumps excel in applications requiring a gentle handling of materials, minimizing shear stress and shear damage. By assessing these design advantages in relation to the specific requirements of your application, including fluid type, pressure, and flow rates, you can make a more informed decision that enhances the reliability and longevity of your pumping system.

Pressure Range Comparison of Different High Pressure Chemical Pumps

This chart compares the pressure ranges in psi for various types of high pressure chemical pumps commonly used in industrial applications. Each type of pump has its unique advantages, making it suitable for specific applications.

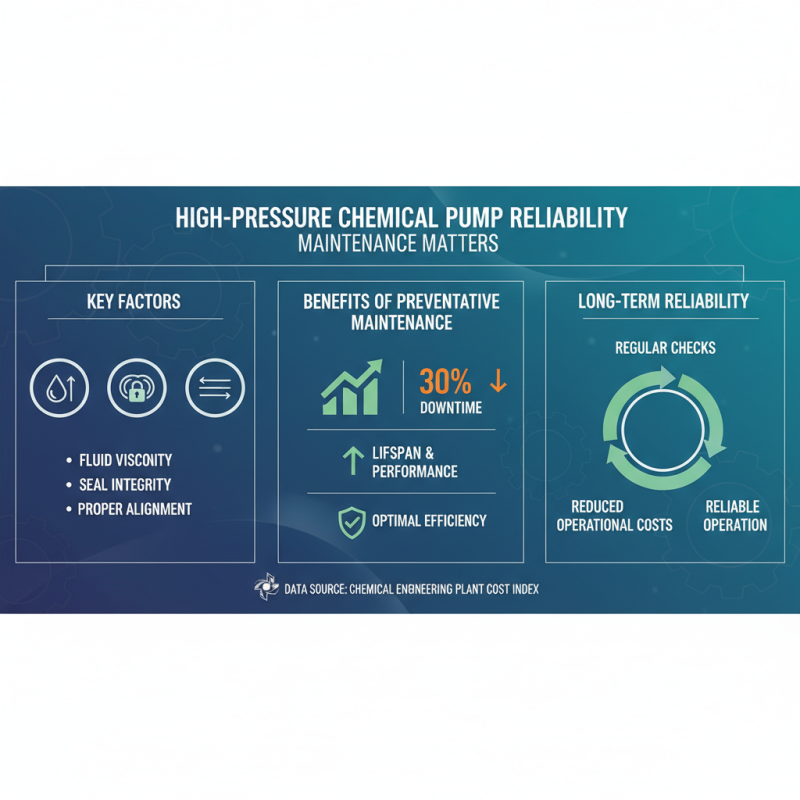

Analyzing Maintenance Needs and Long-Term Reliability Factors

When selecting a high pressure chemical pump for a specific application, understanding the maintenance needs and factors influencing long-term reliability is crucial. Regular maintenance not only extends the lifespan of the pump but also optimizes its performance. According to the Chemical Engineering Plant Cost Index, preventive maintenance can reduce downtime by up to 30%, underscoring its importance in maximizing operational efficiency. Key maintenance activities include monitoring fluid viscosity, checking seal integrity, and ensuring proper alignment, each of which directly affects the pump's reliability and operational costs.

Long-term reliability is another critical consideration. Factors such as material compatibility with the pumped chemicals, operating temperature, and pressure variations play significant roles in determining a pump's lifespan. The American National Standards Institute (ANSI) emphasizes that selecting materials resistant to corrosion and abrasion can significantly reduce failure rates. Additionally, a report from the Hydraulic Institute states that a well-chosen pump, coupled with proactive maintenance, can achieve more than 95% reliability over its operational life. This suggests that upfront investment in the right pump and a robust maintenance regime pays off through enhanced performance and reduced operational interruptions.

Related Posts

-

How to Choose the Best Chemical Pumps for Your Industrial Needs

-

Top 10 Industrial Pumps You Need to Know for Optimal Performance

-

5 Best Chemical Pumps for Efficient Industrial Use

-

Exploring the Innovations in Industrial Pumps: How Cutting-Edge Technology is Revolutionizing Efficiency

-

2025 How to Choose the Right Chemical Pumps for Your Industry Needs

-

2025 Top Pressure Pumps: Key Features, Benefits, and Buying Guide