Blog

- Home

- Blog

Understanding the Benefits of High Pressure Diaphragm Pumps in Industrial Applications

In the realm of industrial applications, the High Pressure Diaphragm Pump stands out as a pivotal technology for various processes. According to a recent report by MarketsandMarkets, the global diaphragm pump market is projected to grow from USD 3.01 billion in 2020 to USD 5.15 billion by 2025, illustrating a compound annual growth rate (CAGR) of 11.3%. This growth can be attributed to the increasing demand for efficient fluid transfer solutions in sectors such as chemical processing, wastewater treatment, and food and beverage manufacturing. High Pressure Diaphragm Pumps offer exceptional advantages, including the ability to handle viscous fluids and slurries, reduced maintenance requirements, and enhanced safety features due to their seal-less design. As industries seek to optimize operational efficiency and reduce downtime, the adoption of High Pressure Diaphragm Pumps is becoming increasingly prevalent, making them an essential component in modern industrial equipment.

Advantages of High Pressure Diaphragm Pumps in Hazardous Environments

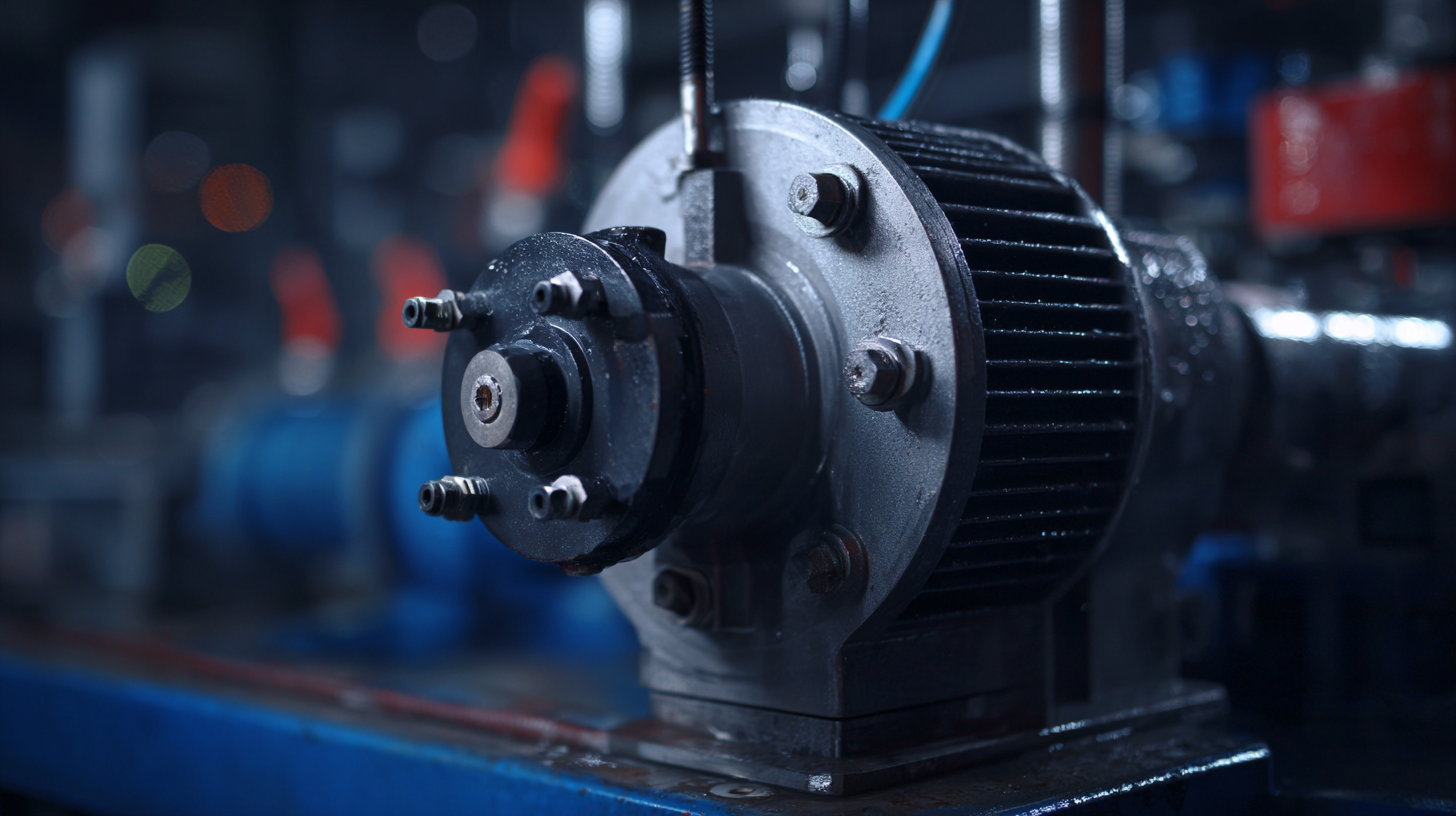

High pressure diaphragm pumps play a crucial role in hazardous environments, offering numerous benefits that enhance safety and efficiency. These pumps are designed to handle a variety of aggressive chemicals and high-pressure applications, making them an ideal choice for industries such as chemicals, oil and gas, and pharmaceuticals.

According to industry reports, the global diaphragm pump market was valued at approximately USD 6.27 billion in 2023 and is expected to increase significantly, reaching nearly USD 9.97 billion by 2032. This growth highlights the rising demand for reliable pumping solutions in environments where safety is paramount.

High pressure diaphragm pumps play a crucial role in hazardous environments, offering numerous benefits that enhance safety and efficiency. These pumps are designed to handle a variety of aggressive chemicals and high-pressure applications, making them an ideal choice for industries such as chemicals, oil and gas, and pharmaceuticals.

According to industry reports, the global diaphragm pump market was valued at approximately USD 6.27 billion in 2023 and is expected to increase significantly, reaching nearly USD 9.97 billion by 2032. This growth highlights the rising demand for reliable pumping solutions in environments where safety is paramount.

One of the notable advantages of high pressure diaphragm pumps is their ability to operate without the risk of leaks, ensuring that hazardous substances are contained effectively. This hermetic sealing reduces the chances of spills or exposures, which is vital in chemical processing and pharmaceutical applications. Furthermore, with advancements such as maintenance-free gearbox and integrated variable drives in newer models, these pumps not only minimize operational downtime but also enhance overall system reliability. The continuous innovation in diaphragm pump technology underscores their significance in managing complex fluid systems safely and efficiently in hazardous environments.

Key Features that Enhance Performance in Industrial Settings

High pressure diaphragm pumps are increasingly being recognized for their performance benefits in various industrial applications. One of their key features is the ability to handle high-viscosity fluids effectively. The diaphragm mechanism provides a seal that prevents leakage, ensuring that even thick or abrasive liquids can be pumped without compromising the integrity of the system. This characteristic is particularly advantageous in industries such as oil and gas, where the transfer of viscous materials is often required.

Another significant feature is their versatility in operating conditions. High pressure diaphragm pumps can function efficiently across a wide range of temperatures and pressures, making them suitable for diverse environments. This adaptability allows industries to use a single type of pump for multiple applications, reducing the need for specialized equipment. Additionally, their ease of maintenance enhances operational efficiency, as routine servicing can be performed quickly without disrupting the production process. The innovation behind these pumps not only streamlines operations but also contributes to increased safety and reduced downtime in industrial settings.

Comparative Analysis: Diaphragm Pumps vs. Other Pump Types

Diaphragm pumps have gained popularity in industrial applications due to their unique design and operational advantages. A comparative analysis reveals that diaphragm pumps offer distinct benefits over traditional centrifugal and screw pumps. According to a report from the Pumps & Systems magazine, diaphragm pumps operate at higher pressures, up to 300 psi, while maintaining a more consistent flow rate. This makes them ideal for transferring viscous fluids and slurries that can clog other types of pumps.

Moreover, diaphragm pumps are inherently safer for handling hazardous materials. The American Society of Mechanical Engineers (ASME) indicates that they have lower chances of leakage due to their sealed design, reducing the risk of contamination. In contrast, centrifugal pumps may experience seal failures, leading to potential safety hazards in industrial settings.

Furthermore, a report from the Fluid Handling Industry shows that diaphragm pumps exhibit a longer lifespan and require less maintenance compared to their counterparts, leading to overall cost savings and increased efficiency in industrial operations.

Applications Across Various Industries Utilizing High Pressure Diaphragm Pumps

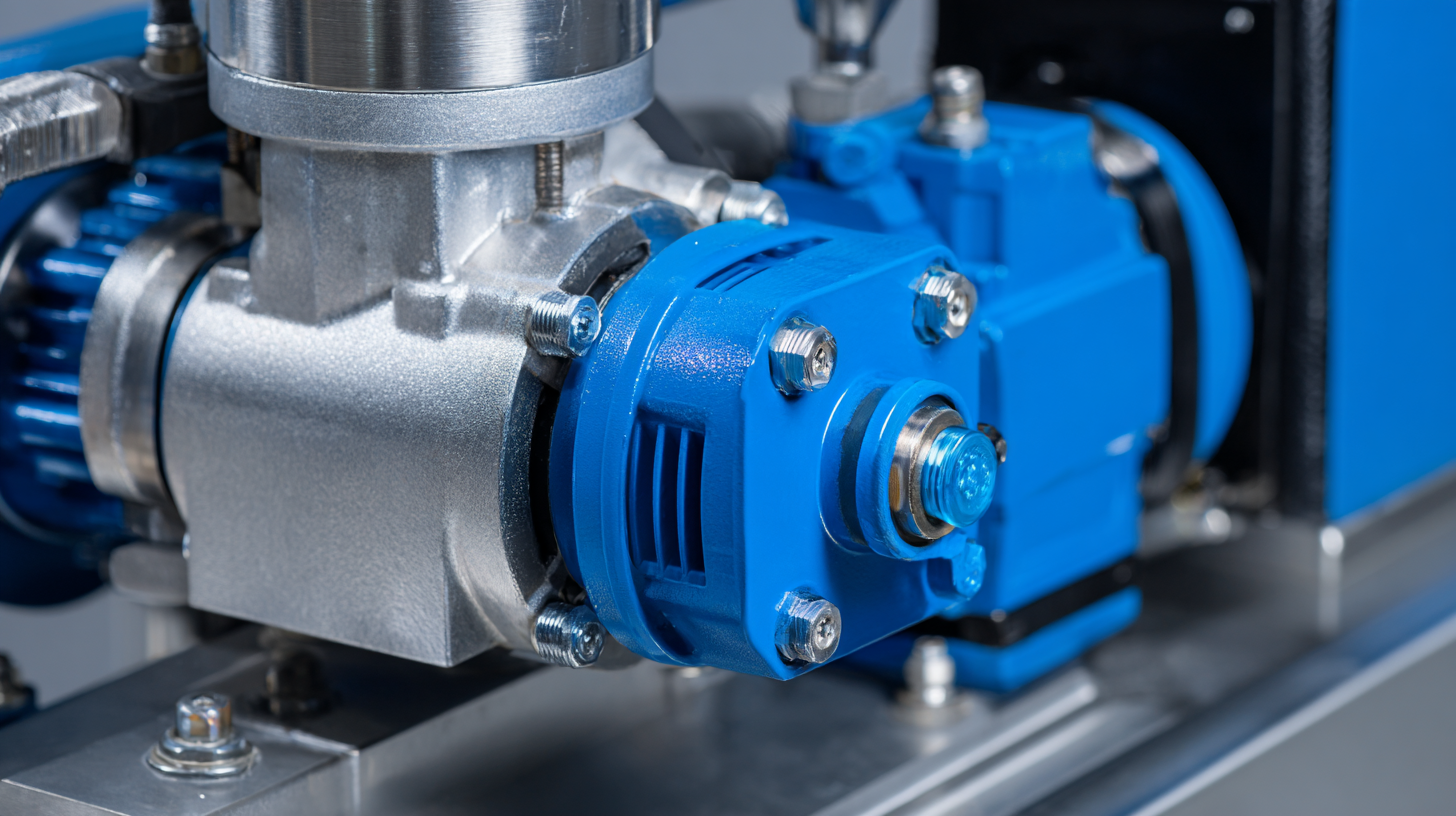

High pressure diaphragm pumps are essential components in various industrial applications due to their versatility and efficiency. One key area of application is the chemical industry, where these pumps handle corrosive fluids and slurries at high pressures, ensuring safe and reliable transport. Their ability to operate under challenging conditions makes them ideal for processes such as chemical dosing, where precision and control are critical. Furthermore, the ease of maintenance and ability to run dry without damage add to their appeal in these demanding environments.

Another significant application of high pressure diaphragm pumps is in the oil and gas sector. Here, they are used for enhanced oil recovery and handling viscous fluids, providing the necessary pressure to move materials through pipelines. Their reliability also plays a crucial role in wastewater treatment processes, where they efficiently transfer sludge and other waste materials under high pressure. The adaptability of these pumps allows them to meet the specific needs of various industries, which is a key factor in their widespread adoption and usage.

Understanding the Benefits of High Pressure Diaphragm Pumps in Industrial Applications

This bar chart illustrates the frequency of usage of high pressure diaphragm pumps across various industrial applications. The data highlights the dominant sectors benefiting from these pumps, where the oil and gas industry leads with the highest usage, followed by water treatment and chemical processing.

Cost Efficiency and Maintenance Benefits of Diaphragm Pumps in Operations

High pressure diaphragm pumps are increasingly becoming the preferred choice in various industrial applications, primarily due to their

cost efficiency and minimal maintenance requirements. These pumps are designed to handle a wide range of fluids,

including corrosive and viscous substances, which makes them versatile for different operational needs. By utilizing a diaphragm mechanism, they ensure a leak-free operation, reducing the need for

frequent repairs and replacements. This inherent reliability translates to lower operational costs, as companies can allocate fewer resources to maintenance and downtime.

High pressure diaphragm pumps are increasingly becoming the preferred choice in various industrial applications, primarily due to their

cost efficiency and minimal maintenance requirements. These pumps are designed to handle a wide range of fluids,

including corrosive and viscous substances, which makes them versatile for different operational needs. By utilizing a diaphragm mechanism, they ensure a leak-free operation, reducing the need for

frequent repairs and replacements. This inherent reliability translates to lower operational costs, as companies can allocate fewer resources to maintenance and downtime.

Moreover, the operational efficiency of diaphragm pumps contributes to overall cost savings. Their ability to maintain high pressure with reduced energy consumption allows industries to operate at lower energy costs. Additionally, the simplicity of their design often means that fewer spare parts are needed, which further decreases overhead expenses. By investing in high pressure diaphragm pumps, companies not only benefit from their robust performance but also enjoy a significant return on investment through enhanced productivity and lower maintenance overheads.

Related Posts

-

10 Tips for Maximizing Efficiency with High Pressure Hydraulic Pumps in Industrial Settings

-

Ultimate Guide to Selecting the Right Hydraulic Diaphragm Pump for Your Industrial Needs

-

5 Best Chemical Pumps for Efficient Industrial Use

-

Top Strategies for Sourcing High Performance Industrial Pumps Globally

-

How to Optimize Pump Water Efficiency for Sustainable Resource Management

-

How to Select the Right Hydraulic Diaphragm Pump for Your Industrial Needs