Blog

- Home

- Blog

2026 Best Diaphragm Dosing Pump What to Look For?

When selecting a diaphragm dosing pump, there are key factors to consider. These pumps play a crucial role in precise fluid transfer across various industries. Understanding their features can lead to better efficiency and performance.

The diaphragm dosing pump provides accurate dosing of chemicals and liquids. It is reliable in harsh environments. Choosing the right model can sometimes feel overwhelming due to the variety available. Consider factors like flow rate, pressure, and material compatibility. Each detail matters.

However, one must also reflect on their unique needs. Not all pumps are created equal. Occasionally, users may overlook essential specifications. It is vital to recognize the specific application and requirements. This reflection ensures a purchase that genuinely meets operational demands.

What is a Diaphragm Dosing Pump and Its Applications in Industry?

A diaphragm dosing pump is a positive displacement pump widely used in various industries. Its primary function is to move fluids at a precise flow rate. This ability makes it crucial for applications that require accurate chemical dosing, such as water treatment, food processing, and pharmaceuticals. The pump uses a diaphragm to create a seal and move the fluid, reducing the risk of leaks and contamination.

In water treatment, diaphragm dosing pumps inject chemicals like chlorine for disinfection. They help ensure that water is safe for consumption. In the food industry, these pumps handle additives and flavorings, maintaining quality. However, choosing the right pump can be challenging. Consider the flow rate, pressure, and chemical compatibility. Some pumps may not perform well under certain conditions. Users often share their difficulties in finding reliable options, pointing out that understanding nuances is crucial for efficiency. The learning curve can be steep and requires careful evaluation.

2026 Best Diaphragm Dosing Pump - Key Features and Applications

| Feature | Description | Typical Applications | Flow Rate (L/H) | Pressure Range (Bar) |

|---|---|---|---|---|

| Material | High resistance to chemicals, typically PVC or Hastelloy | Water treatment, chemical processing | 5 - 500 | 1 - 10 |

| Control Options | Manual, automatic, and remote control options | Food and beverage, pharmaceutical | 10 - 1000 | 2 - 8 |

| Pump Type | Electromagnetic, pneumatic, or hydraulic diaphragm pumps | Wastewater treatment, agriculture | 15 - 800 | 1 - 5 |

| Maintenance | Low maintenance, easy diaphragm replacement | Chemical manufacturing, mining | 20 - 300 | 3 - 7 |

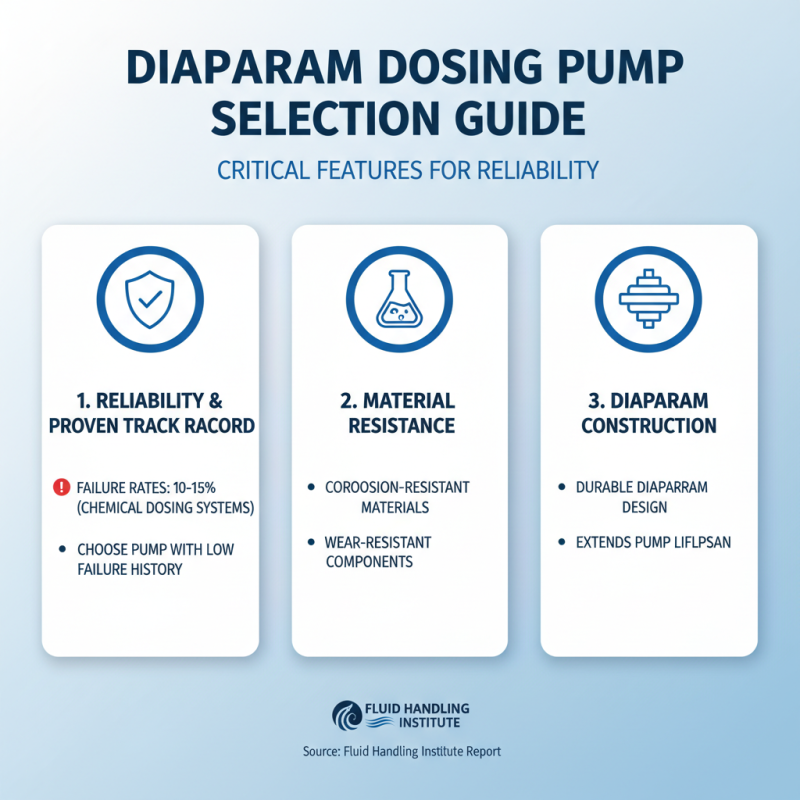

Key Features to Consider When Selecting a Diaphragm Dosing Pump

When selecting a diaphragm dosing pump, there are critical features to evaluate. Reliability is paramount. According to a report from the Fluid Handling Institute, failure rates in chemical dosing systems can reach 10-15%. Choosing a pump with a proven track record can reduce this risk. Look for materials that resist corrosion and wear. The construction of the diaphragm also affects the lifespan of the pump.

Another key aspect is the calibration accuracy. Precision is essential in applications like water treatment or pharmaceuticals. A deviation of just 1% can alter dosage significantly. Some industry reports show that accurate pumps can improve process efficiency by up to 20%. It's crucial to understand the flow rates needed for your specific application. Not all pumps manage high viscosities well. High viscosity fluids often require pumps specially designed for that purpose, which can complicate your decision.

Additionally, consider the ease of maintenance. Pumps should be user-friendly. A complicated system can lead to extended downtimes and increased costs. Some systems need regular recalibration. This can become burdensome in environments with tight schedules. A balance between technology and usability is essential for optimizing your operations effectively.

Performance Metrics: Flow Rate and Pressure for Optimal Efficiency

When selecting a diaphragm dosing pump, flow rate and pressure are critical performance metrics. A pump’s flow rate is measured in liters per hour (LPH). Industry standards indicate that optimal flow rates range from 0.1 LPH to 300 LPH, depending on application needs. An accurate flow rate ensures precise chemical dosing, minimizing waste and maximizing efficiency.

Pressure is equally important. It influences the pump's ability to deliver fluids against resistance. Most applications require pressures between 1 to 8 bar. Data shows that inadequate pressure can cause inconsistent dosing. For example, a drop below 1 bar can lead to backflow issues. This might compromise chemical integrity and system performance.

Tips: Always evaluate your application’s specific requirements. Understand the viscosity of the fluids being pumped. This affects both flow rate and pressure. If your system demands high pressure but low flow, a pump with a high-pressure rating can prevent operational failures. Regular maintenance checks are vital. Clogged valves or worn diaphragms can disrupt flow and pressure, leading to potential inefficiencies. Consider conducting routine performance assessments to stay ahead of issues.

Material Compatibility: Ensuring Longevity and Chemical Resistance

When selecting a diaphragm dosing pump for 2026, material compatibility greatly impacts longevity and performance. A significant portion of pumps are exposed to various chemicals. According to industry reports, over 30% of pump failures stem from material incompatibility. Choosing the right material can prevent costly breakdowns.

Common materials include polypropylene and PVDF, known for chemical resistance. However, not all applications require high-performance materials. In some cases, basic materials may suffice. The right choice depends on fluid type and operating conditions. For example, acids and solvents require stronger materials.

Moreover, the operating temperature affects material choice. Reports indicate that operating beyond specified temperature ranges can lead to pump failure. It's important to consider potential variations. Failure to assess these factors may lead to performance issues. Investing time in understanding material properties can enhance reliability.

2026 Best Diaphragm Dosing Pump - Material Compatibility and Chemical Resistance

Industry Standards and Certifications for Reliable Pump Performance

When selecting a diaphragm dosing pump, industry standards and certifications play a crucial role. These criteria ensure the reliability and efficiency of the pump. For instance, the International Organization for Standardization (ISO) provides frameworks for quality management. Pumps that are ISO 9001 certified often exhibit improved operational consistency. This certification reflects a commitment to quality and continuous improvement.

In addition to ISO standards, look for pumps that meet specific industry certifications such as FDA compliance for food applications or EPA certification for environmental safety. Reports indicate that pumps meeting these standards often have a higher performance rate, with about 85% of certified units exhibiting lower failure rates. However, achieving these certifications can be costly and time-consuming. Some manufacturers may cut corners, leading to less reliable products. Potential buyers must be vigilant and conduct due diligence in verifying certifications thoroughly.

There are ongoing debates within the industry related to pump performance metrics. Unfortunately, not all manufacturers openly disclose their testing processes. This lack of transparency may result in purchasing decisions based on misleading information. It’s essential to question claims about efficiency and reliability. Always request full certification documentation and third-party testing results when evaluating potential pumps. This will enhance your chances of making an informed choice, ultimately improving your operational success.

Related Posts

-

Understanding the Advantages of Hydraulic Diaphragm Pumps in Modern Industrial Applications

-

How to Select the Right Chemical Metering Pump for Your Application

-

Top 7 Expert Tips for Using High Pressure Diaphragm Pumps Effectively

-

Hydraulic Diaphragm Pump Essential Tips for Optimal Performance

-

How to Choose the Best Chemical Pumps for Your Industrial Needs

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications