Blog

- Home

- Blog

Understanding the Mechanisms Behind Pressure Pumps in Everyday Applications

Pressure pumps play a vital role in a multitude of everyday applications, ranging from industrial processes to household usage. According to a report by MarketWatch, the global pump market is projected to reach $90 billion by 2025, with pressure pumps accounting for a significant segment of this growth. These devices are designed to move fluids by converting mechanical energy into hydraulic energy, making them essential in various sectors including agriculture, manufacturing, and water management. Understanding the mechanisms behind pressure pumps is crucial not only for optimizing efficiency but also for minimizing energy consumption and operational costs.

Pressure pumps play a vital role in a multitude of everyday applications, ranging from industrial processes to household usage. According to a report by MarketWatch, the global pump market is projected to reach $90 billion by 2025, with pressure pumps accounting for a significant segment of this growth. These devices are designed to move fluids by converting mechanical energy into hydraulic energy, making them essential in various sectors including agriculture, manufacturing, and water management. Understanding the mechanisms behind pressure pumps is crucial not only for optimizing efficiency but also for minimizing energy consumption and operational costs.

Recent advancements in technology have further enhanced the performance and reliability of pressure pumps, fostering innovations that meet the increasing demands of various industries. By delving into the specific types and functions of pressure pumps, we can better appreciate their impact on our daily lives and the economy at large.

Key Functions and Types of Pressure Pumps in Daily Life

Pressure pumps play a crucial role in various everyday applications, ensuring the effective delivery of fluids in both industrial and residential settings. Among the key functions of pressure pumps are water distribution, irrigation, and fluid transfer. For instance, in residential water systems, pressure pumps can elevate water from wells and reservoirs to ensure sufficient pressure in plumbing systems. According to a report by the Hydraulic Institute, nearly 40% of all pumps in use globally are categorized as pressure pumps, highlighting their significance in modern infrastructure.

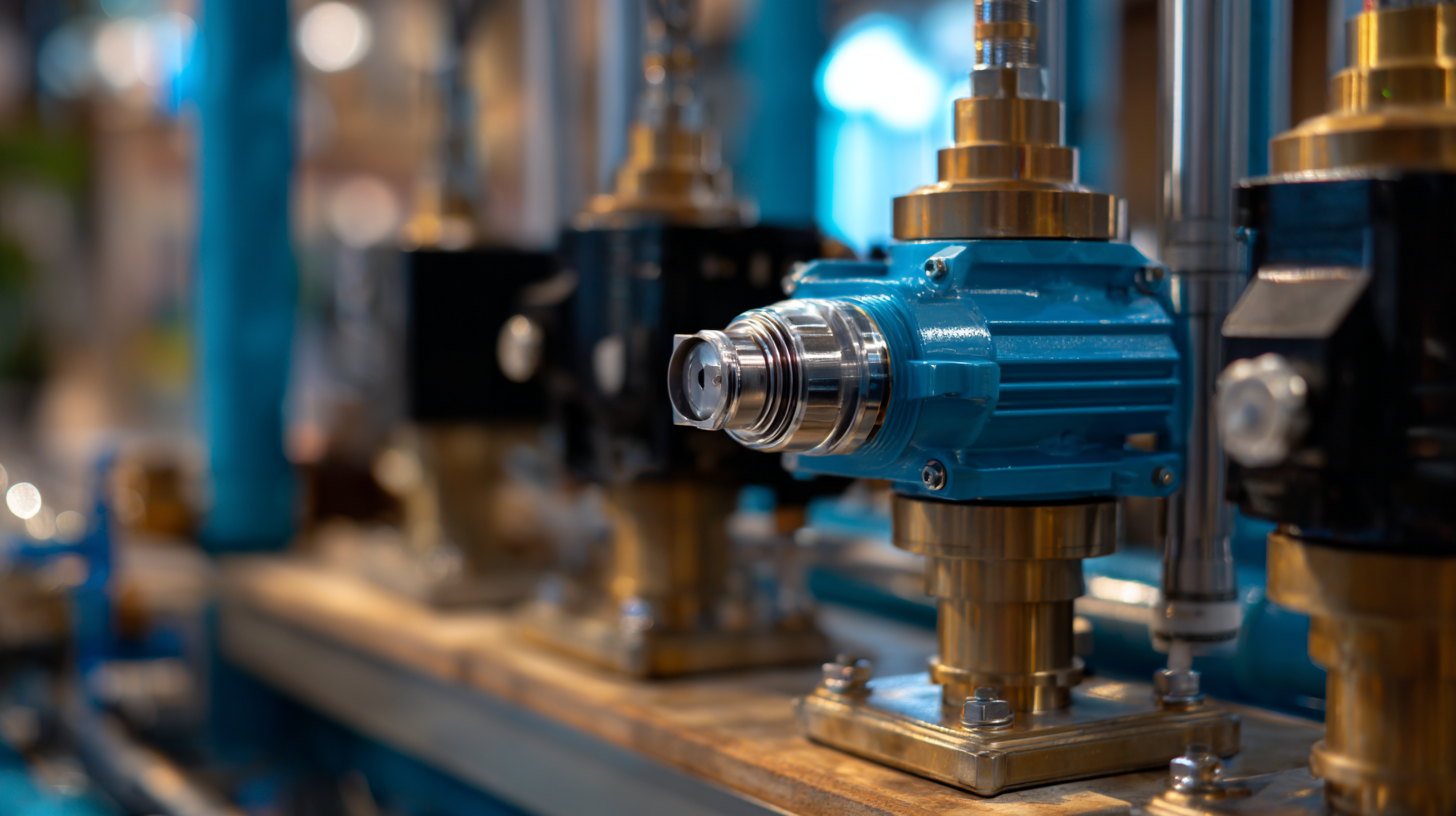

Different types of pressure pumps are utilized based on specific needs, including centrifugal pumps, positive displacement pumps, and diaphragm pumps. Centrifugal pumps are widely employed in household applications for water supply, providing a reliable means of maintaining consistent flow rates. On the other hand, positive displacement pumps, such as gear and screw pumps, are favored in industries where precise fluid handling is required. The global market for pressure pumps is expected to reach $25 billion by 2026, driven by advancements in technology and increased demand in sectors such as agriculture, construction, and wastewater management. This growth underscores the necessity of understanding various pump types and their functions to optimize usage in everyday applications.

How Pressure Pumps Enhance Efficiency in Household Appliances

Pressure pumps play a crucial role in enhancing the efficiency of various household appliances. In applications like dishwashers and washing machines, these pumps ensure a consistent flow of water, optimizing cleaning processes. By pressurizing water, these pumps facilitate the effective movement of water through pipes and jets, enabling appliances to perform at peak efficiency. This not only results in cleaner dishes and laundry but also conserves water, making these devices more environmentally friendly.

Moreover, in systems like home heating and cooling, pressure pumps enhance performance by maintaining appropriate fluid circulation. This ensures that rooms reach desired temperatures quickly and consistently, thereby reducing energy consumption. The ability of pressure pumps to adjust water flow based on demand helps appliances operate more efficiently, thereby extending their lifespan and reducing maintenance costs. As households increasingly seek energy-efficient solutions, the role of pressure pumps in everyday appliances cannot be underestimated; they are essential components that drive both effectiveness and sustainability in the home.

Understanding the Mechanisms Behind Pressure Pumps in Everyday Applications - How Pressure Pumps Enhance Efficiency in Household Appliances

| Application | Pressure Pump Type | Efficiency Gain (%) | Common Uses | Maintenance Frequency (Months) |

|---|---|---|---|---|

| Dishwasher | Centrifugal Pump | 15 | Water circulation and spraying | 12 |

| Washing Machine | Positive Displacement Pump | 20 | Water supply and drainage | 6 |

| Refrigerator | Reciprocating Pump | 10 | Cooling fluid circulation | 24 |

| Coffee Maker | Diaphragm Pump | 25 | Water heating and brewing | 3 |

| Shower System | Turbo Pump | 30 | Water pressure increase | 18 |

The Role of Pressure Pumps in Industrial Applications

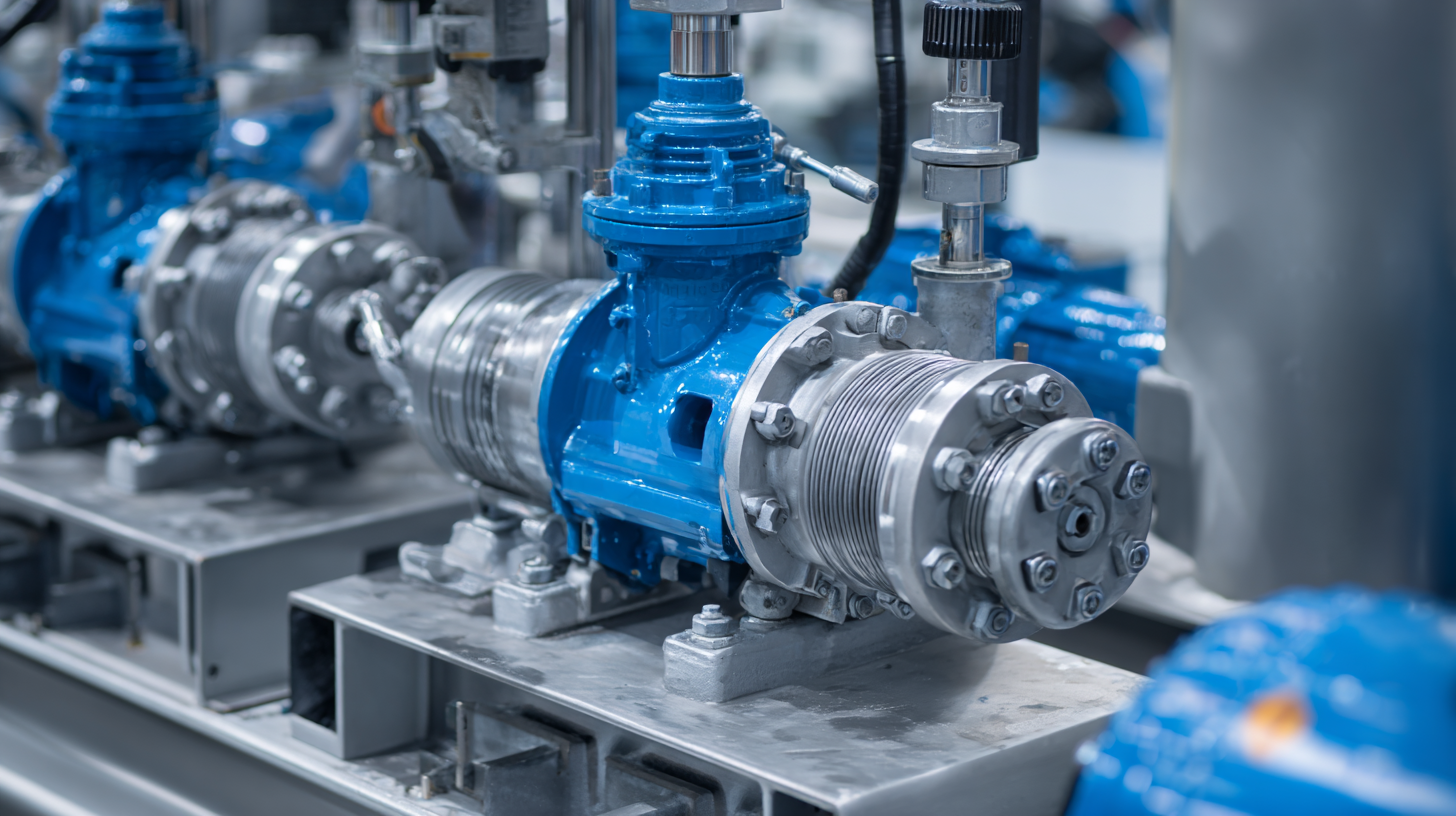

Pressure pumps play a crucial role in a wide range of industrial applications, from manufacturing to oil extraction. These pumps are designed to move fluids through a system by converting mechanical energy into hydraulic energy, creating pressure that allows fluids to flow efficiently. In factories, pressure pumps are vital for processes like cooling systems, where they circulate water, preventing overheating of machinery. In the oil and gas sector, these pumps facilitate the extraction and transportation of crude oil, ensuring that the flow rate is maintained for optimal productivity.

**Tips for Choosing the Right Pressure Pump:**

When selecting a pressure pump for industrial use, consider the type of fluid being pumped and its viscosity. A pump designed for water may not be suitable for thicker fluids like oil or chemicals. Additionally, evaluate the required pressure and flow rate for your application to ensure the pump meets the operational demands.

Moreover, regular maintenance of pressure pumps is essential for longevity and efficiency. Keeping the components, such as seals and filters, in optimal condition prevents leaks and reduces downtime, thus enhancing productivity in industrial settings. By being proactive in maintenance, industries can save costs and extend the life of their pressure pump systems.

Understanding the Mechanisms Behind Pressure Pumps in Everyday Applications

This bar chart illustrates the distribution of pressure pump applications across various industrial sectors, highlighting their significance in everyday uses.

Common Challenges and Maintenance Tips for Pressure Pumps

Pressure pumps are essential in a variety of applications, ranging from household water systems to industrial processes. However, they often face common challenges that can impact performance and longevity. According to a report by the Hydraulic Institute, nearly 30% of pump failures are attributed to inadequate maintenance practices. Regular inspections, cleaning, and replacing worn parts are crucial steps to ensure optimal functionality.

One prevalent issue is cavitation, which occurs when vapor bubbles form in the liquid and collapse within the pump. This phenomenon can lead to significant damage, including erosion of internal components. To mitigate this risk, it is recommended to maintain a proper Net Positive Suction Head (NPSH) and avoid running the pump under excessive load. Furthermore, keeping an eye on pressure fluctuations can help identify potential problems early. The American Society of Mechanical Engineers (ASME) emphasizes the importance of monitoring and adjusting operating conditions to enhance pump reliability and maintain efficiency.

Regular monitoring and maintenance can significantly reduce operational disruptions and enhance the lifespan of pressure pumps. As per data from the American Pump Manufacturer's Association, scheduled maintenance can prolong the life of a pump by up to 50%, resulting in substantial cost savings over time. By addressing these common challenges and adhering to maintenance best practices, users can ensure optimal performance in their pressure pump systems.

Innovations in Pressure Pump Technology for Modern Solutions

Innovations in pressure pump technology have fundamentally transformed a variety of industries, making everyday applications more efficient and sustainable. The latest advancements leverage smart materials and IoT integration, allowing for real-time monitoring and enhanced control over pump performance. This technology enables users to adjust settings from remote locations, optimizing energy use and reducing waste in applications ranging from residential plumbing to industrial processes.

Additionally, advancements in miniaturization and design have opened new possibilities for pressure pumps in compact and mobile applications. Modern pumps are not only more powerful but also quieter and more reliable, leading to improved user experiences. Innovations such as variable speed drives and self-priming mechanisms further increase their versatility, catering to diverse needs—from agricultural irrigation to HVAC systems. As these technologies continue to evolve, they promise to deliver more intelligent and efficient solutions that meet the demands of contemporary life.

Related Posts

-

5 Innovative Ways Pressure Pumps Enhance Industrial Efficiency

-

7 Best Practices for Choosing a High Pressure Metering Pump

-

What Makes Plunger Metering Pump Essential for Precision Fluid Control

-

How to Choose the Right High Pressure Pump for Your Industrial Needs

-

Innovative Solutions for Plunger Metering Pump Applications

-

Unlocking Efficiency: The Significant Advantages of Plunger Metering Pumps in Process Industries