Blog

- Home

- Blog

Top 10 High Pressure Metering Pumps for Efficient Chemical Processing

In the realm of chemical processing, the efficiency and precision of fluid handling are paramount. High Pressure Metering Pumps play a critical role in various industries such as pharmaceuticals, petrochemicals, and water treatment. According to a recent report by MarketsandMarkets, the global metering pump market is projected to reach USD 5.4 billion by 2026, driven by the increasing demand for accurate chemical dosing in manufacturing processes. This underscores the vital importance of selecting the right metering technology to ensure operational excellence.

Dr. Emily Thompson, a leading expert in fluid dynamics, emphasizes the significance of High Pressure Metering Pumps in achieving optimal chemical processing. She states, "The reliability and accuracy of metering pumps directly influence the overall efficiency of chemical reactions." Her insights highlight how advanced metering solutions not only enhance process efficiency but also contribute to reduced operational costs and waste minimization. As industries continue to evolve, the demand for sophisticated High Pressure Metering Pumps remains crucial in meeting both regulatory standards and market expectations.

This article will delve into the top 10 high-pressure metering pumps available today, offering insights into their features, benefits, and applications, providing a comprehensive guide for professionals looking to elevate their chemical processing operations.

The Importance of High Pressure Metering Pumps in Chemical Processing

High-pressure metering pumps play a critical role in chemical processing by ensuring the precise delivery of fluids under high pressure. According to a recent report by MarketsandMarkets, the global market for metering pumps is projected to reach $7.6 billion by 2024, driven by rising demand for accurate dosing in various industries, including water treatment and pharmaceuticals. The ability of these pumps to maintain consistent flow rates even in challenging environments significantly enhances efficiency in chemical processing operations.

Furthermore, high-pressure metering pumps are essential for optimizing chemical reactions where precise concentrations are needed. A study by Frost & Sullivan highlights that inaccuracies in fluid delivery can lead to production inefficiencies and increased waste, costing companies approximately 5-10% of their operational budgets. By employing high-pressure metering technology, manufacturers can mitigate these risks, ensuring that chemical dosages are both accurate and reliable, ultimately contributing to lower costs and improved product quality in the long run.

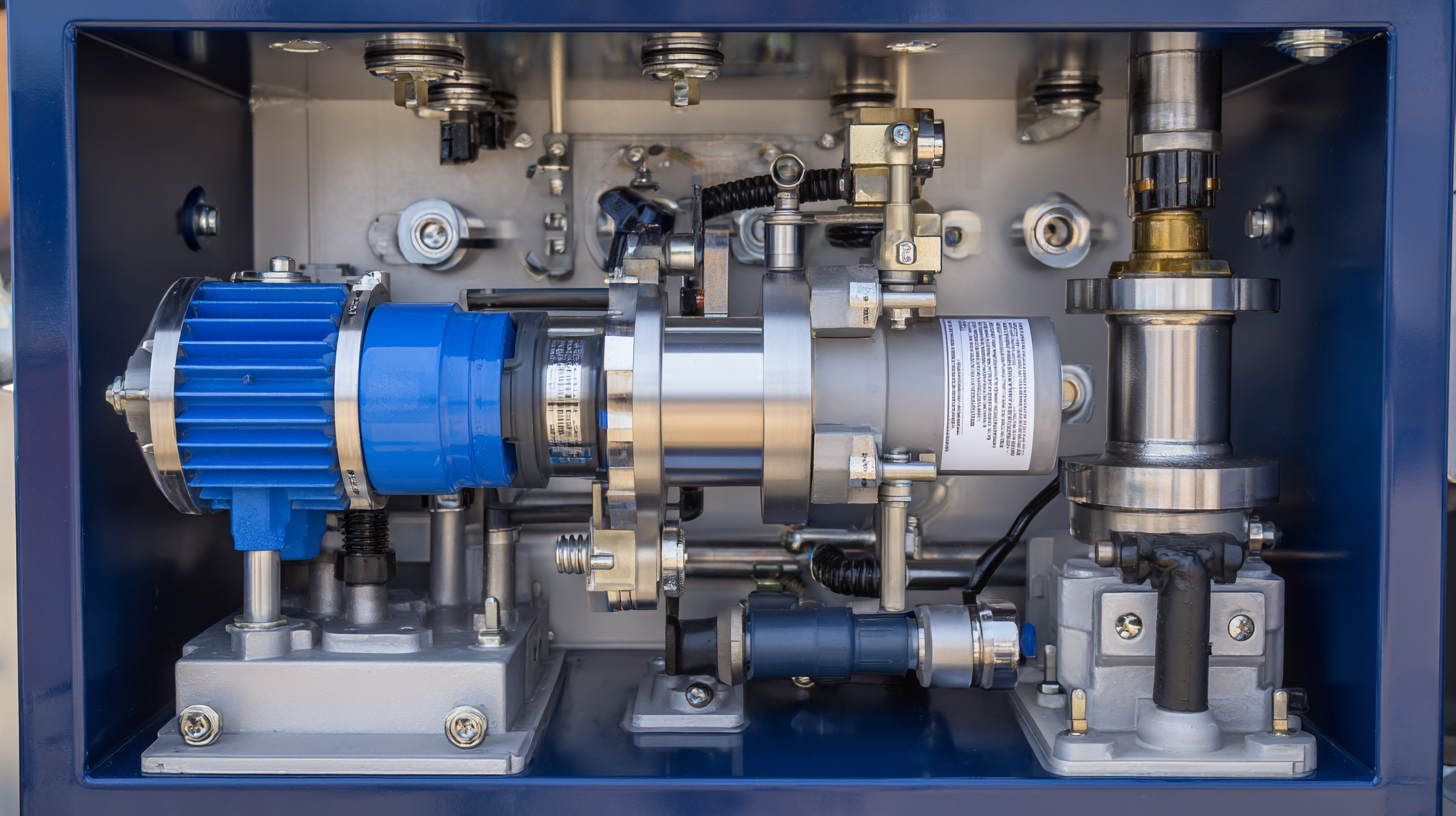

Key Features to Consider When Selecting a High Pressure Metering Pump

When selecting a high pressure metering pump for efficient chemical processing, several key features should be considered to ensure optimal performance and reliability. Firstly, the pump's maximum pressure rating is crucial; it must exceed the operational requirements of your specific application to handle varying liquid densities and viscosities without compromising efficiency. Look for pumps that offer precise flow control, which can often be achieved through adjustable stroke lengths and speeds—this ensures accurate dosing and minimizes waste.

Another important factor is the material of construction. Pumps made of corrosion-resistant materials, such as PVC, PTFE, or stainless steel, are essential when handling aggressive chemicals. Additionally, compatibility with different fluids should be assessed to prevent damage and ensure a long service life. Finally, consider the ease of maintenance and servicing; pumps designed for straightforward component access and cleaning can save time and reduce downtime in your processing operations, further enhancing productivity.

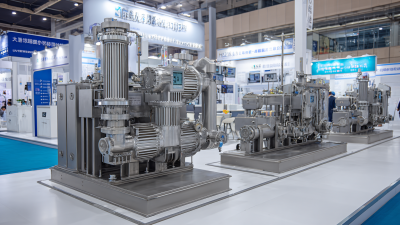

Comparison of Top 10 High Pressure Metering Pumps for Performance

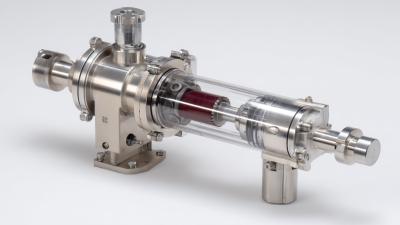

High pressure metering pumps play a crucial role in the efficiency of chemical processing, particularly in high performance liquid chromatography (HPLC) applications. These pumps are designed to deliver precise flow rates under varying conditions, making them essential for accurate and reliable results. Recent developments highlight advancements in pump technology, including models that promise enhanced performance and lower maintenance needs while ensuring high uptime. Brands are increasingly focusing on creating smarter alternatives that outperform traditional syringe pumps, indicating a trend toward improved precision and ease of use in fluid dispensing.

In comparing the top high pressure metering pumps, various factors such as flow rate stability, pressure capability, and ease of integration into existing systems come into play. Market forecasts indicate robust growth, with the metering pumps market continuing to expand due to increased demand in chemical processing and other applications. Continuous innovation in pump design, such as the integration of intelligent algorithms for performance prediction, highlights the ongoing evolution in this sector. These advancements enable operators to optimize processes and ensure that they maintain compliance with industry standards while meeting the specific needs of their applications.

Applications of High Pressure Metering Pumps Across Various Industries

High-pressure metering pumps are essential in various industries, particularly where precise chemical dosing is critical. In the oil and gas sector, these pumps facilitate the accurate injection of chemicals to enhance oil recovery rates. Reports indicate that the global market for chemical injection systems is expected to grow by 6.5% annually, highlighting the increasing demand for reliable pumping solutions in this field. Additionally, in water treatment facilities, high-pressure metering pumps are employed to ensure the correct dosage of treatment chemicals, improving efficiency and compliance with regulatory standards.

Chemicals in the pharmaceutical industry also benefit from the accuracy and reliability of high-pressure metering pumps. According to a recent industry study, 75% of pharmaceutical manufacturers prioritize metering accuracy as a vital factor in their production processes. This precision contributes significantly to product quality and regulatory compliance, ultimately impacting patient safety and product efficacy.

Tip: When selecting a high-pressure metering pump, consider the specific chemical properties and temperature ranges of your application. Ensuring compatibility can prevent damage to both the pump and the fluids being processed.

Furthermore, in agricultural settings, these pumps play a crucial role in fertigation systems. By allowing precise application of fertilizers and pesticides, they not only improve crop yields but also promote sustainable practices by minimizing chemical runoff.

Tip: Regular maintenance and recalibration of metering pumps can lead to improved longevity and performance, ensuring that your operations remain efficient and cost-effective.

Top 10 High Pressure Metering Pumps for Efficient Chemical Processing

This chart displays the flow rates of the top 10 high pressure metering pumps used in various chemical processing applications. Higher flow rates are essential for efficient operation in multiple industries such as pharmaceuticals, petrochemicals, and food processing.

Maintenance Tips for Ensuring Longevity of High Pressure Metering Pumps

When it comes to maintaining high pressure metering pumps for efficient chemical processing, regular upkeep is essential to ensure their longevity and optimal performance. One of the primary maintenance tips is to routinely inspect components for wear and tear. This includes checking seals, gaskets, and pump housing for any signs of leakage or damage. Keeping all moving parts well-lubricated and replacing worn components promptly can prevent costly breakdowns and maintain the pump's efficiency.

Furthermore, proper cleaning and flushing of the pump after use are crucial, especially when handling corrosive or viscous materials. This practice not only removes residual build-up but also helps in maintaining the integrity of the pump’s components. Adopting a preventive maintenance schedule can significantly extend the lifespan of these pumps, thereby ensuring consistent performance in chemical processing applications. Regular training for operators on proper handling and maintenance procedures also contributes to minimizing potential risks associated with equipment failure.

Top 10 High Pressure Metering Pumps for Efficient Chemical Processing

| Pump Model | Max Flow Rate (L/h) | Max Pressure (bar) | Material Compatibility | Efficiency (%) | Maintenance Interval (months) |

|---|---|---|---|---|---|

| Model A | 300 | 15 | Acids, Bases | 90 | 12 |

| Model B | 250 | 20 | Solvents | 85 | 10 |

| Model C | 400 | 12 | Chemicals | 92 | 15 |

| Model D | 350 | 18 | Food Grade | 88 | 11 |

| Model E | 200 | 22 | Neutral Liquids | 80 | 9 |

| Model F | 450 | 16 | Acidic Solutions | 89 | 14 |

| Model G | 500 | 10 | Corrosive Fluids | 91 | 16 |

| Model H | 275 | 19 | Polymer Solutions | 84 | 8 |

| Model I | 390 | 13 | Industrial Chemicals | 93 | 12 |

| Model J | 320 | 25 | Water Based Solutions | 86 | 10 |

Related Posts

-

Exploring the Impact of Diaphragm Metering Pumps at the 138th China Import and Export Fair 2025

-

How to Select the Right Chemical Metering Pump for Your Application

-

Understanding the Efficiency and Applications of Plunger Metering Pumps in Industrial Settings

-

Understanding the Mechanisms Behind Pressure Pumps in Everyday Applications

-

Innovative Solutions for Plunger Metering Pump Applications

-

Unlocking Efficiency: The Significant Advantages of Plunger Metering Pumps in Process Industries