Blog

- Home

- Blog

Understanding Diaphragm Pumps: Key Technologies and Their Impact on Fluid Transfer Efficiency

Diaphragm pumps have emerged as a vital solution in the fluid transfer industry, known for their reliability and versatility across various applications. According to a recent market report by Research and Markets, the global diaphragm pump market is projected to reach USD 4.37 billion by 2026, growing at a CAGR of 5.8% from 2021. This surge can be attributed to the increasing demand for efficient and safe transfer of liquids in sectors such as chemical processing, water and wastewater treatment, and food and beverage. The unique design of diaphragm pumps enables them to handle abrasive, viscous, and corrosive fluids effectively, thereby enhancing transfer efficiency and reducing maintenance costs. Furthermore, advancements in diaphragm pump technology, such as the development of smart pumps and improved materials, are paving the way for more energy-efficient operations, positioning diaphragm pumps as an indispensable component in the quest for sustainable fluid handling solutions.

How Diaphragm Pumps Work: Fundamentals of Design and Operation

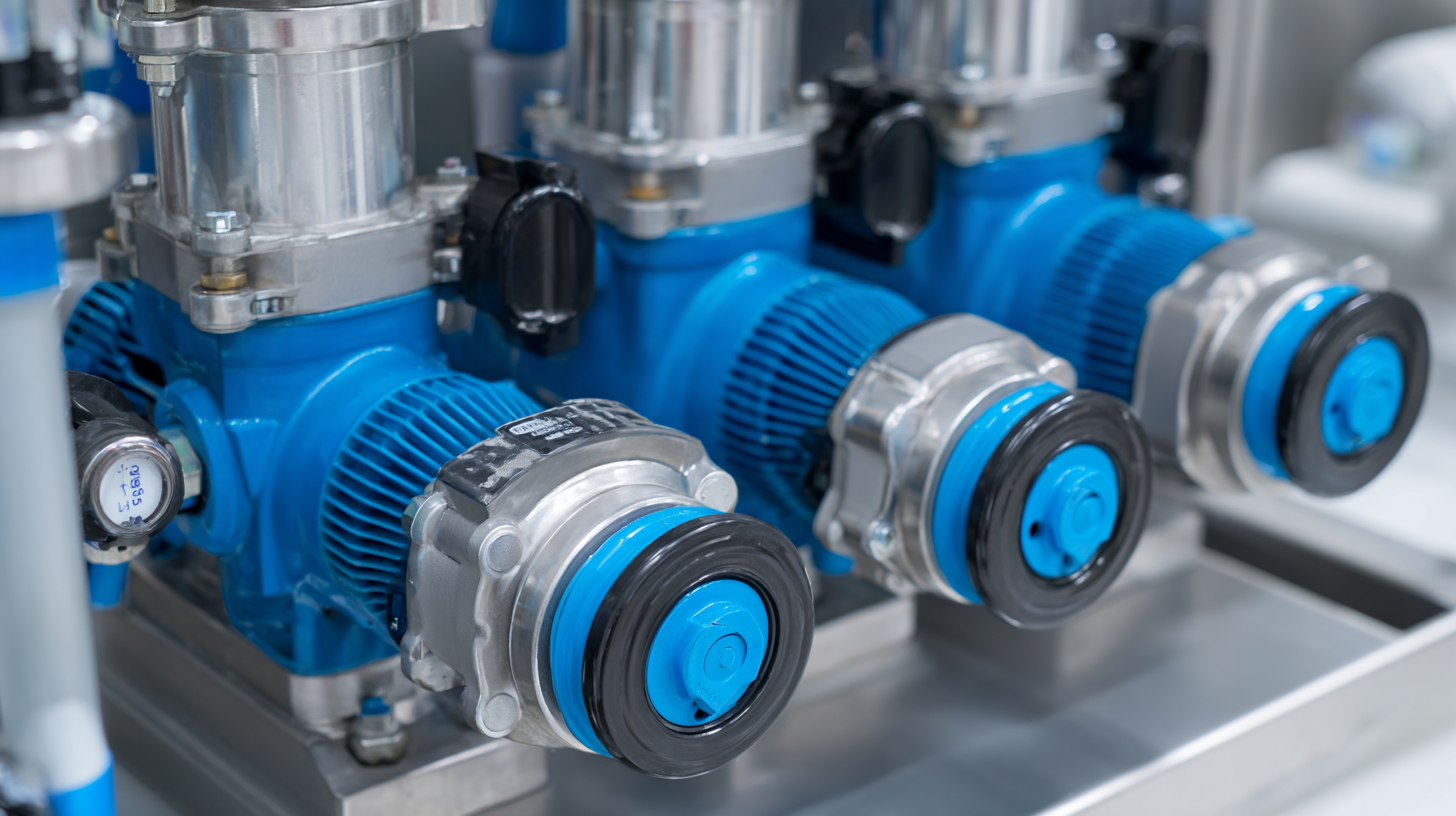

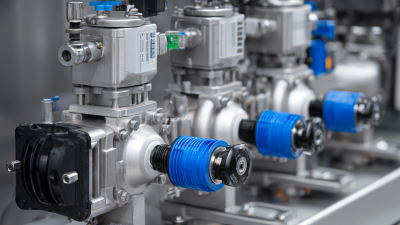

Diaphragm pumps are crucial in a variety of applications, leveraging their unique design to efficiently transfer fluids. At the core of their operation is the flexible diaphragm, which acts as a barrier to separate the pump chamber from the fluid being moved. As the diaphragm moves up and down, it creates a pressure differential that draws liquid into the pump during the intake stroke and expels it during the discharge stroke. This fundamental mechanism enables diaphragm pumps to handle viscous, abrasive, or corrosive fluids with minimal risk of leakage or contamination.

Diaphragm pumps are crucial in a variety of applications, leveraging their unique design to efficiently transfer fluids. At the core of their operation is the flexible diaphragm, which acts as a barrier to separate the pump chamber from the fluid being moved. As the diaphragm moves up and down, it creates a pressure differential that draws liquid into the pump during the intake stroke and expels it during the discharge stroke. This fundamental mechanism enables diaphragm pumps to handle viscous, abrasive, or corrosive fluids with minimal risk of leakage or contamination.

Tip: Regular maintenance of diaphragm pumps is essential to ensure optimal performance. Inspecting and replacing worn diaphragms can prevent inefficient operation and prolong the lifespan of the pump.

The versatility of diaphragm pumps allows them to be used in diverse sectors, from chemical processing to food and beverage applications. Their ability to self-prime and handle various flow rates makes them ideal for situations where consistency and reliability are paramount. Understanding the specific design components, such as valve types and diaphragm materials, can also enhance fluid transfer efficiency significantly.

Tip: When selecting a diaphragm pump, consider the fluid properties and operating conditions. Matching the pump’s specifications with the application requirements is key to improving performance and reducing downtime.

Comparative Analysis: Diaphragm Pumps vs. Traditional Pumping Technologies

Diaphragm pumps are increasingly gaining traction in various industries due to their efficiency in fluid transfer, especially when compared to traditional pumping technologies. In North America, the utility pump market is projected to reach a value of $2.14 billion by 2024, with an anticipated growth to $2.23 billion in 2025 and further to $3.04 billion by 2032. This significant growth reflects the industry's shift toward more innovative and effective pumping solutions, including diaphragm and other advanced pump technologies.

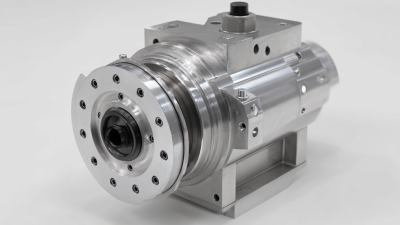

The recent discussions around magnetic suspension technology, particularly in the context of magnetic levitation bearing pumps, represent a crucial innovation within the diaphragm pump sector. As noted in market evaluations, the pneumatic diaphragm pump market is expected to experience a compound annual growth rate of 7.0% from 2024 to 2030, highlighting a growing preference for these advanced technologies. With applications ranging from high-end manufacturing to micro-electronics, the integration of magnetic levitation technology could further enhance the performance of diaphragm pumps, optimizing fluid transfer efficiency and reducing operational costs.

Understanding Diaphragm Pumps: Key Technologies and Their Impact on Fluid Transfer Efficiency

| Pumping Technology | Fluid Transfer Efficiency (%) | Maintenance Frequency (Months) | Operating Pressure (psi) | Typical Applications |

|---|---|---|---|---|

| Diaphragm Pump | 85 - 90 | 6 | 10 - 100 | Chemical Transfer, Food Processing |

| Centrifugal Pump | 70 - 80 | 12 | 20 - 150 | Water Supply, HVAC Systems |

| Gear Pump | 75 - 85 | 10 | 30 - 200 | Oil Transfer, Lubrication Systems |

| Peristaltic Pump | 80 - 88 | 5 | 15 - 50 | Pharmaceuticals, Wastewater Management |

Key Components of Diaphragm Pumps: Materials and Their Performance Impact

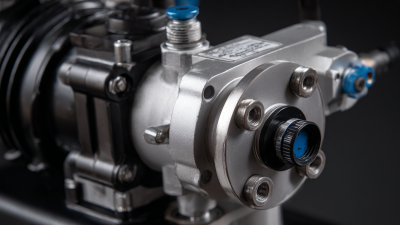

Diaphragm pumps are critical components in various fluid transfer applications, and the choice of materials significantly impacts their performance. The materials used in diaphragm construction can affect chemical compatibility, durability, and efficiency. For instance, select elastomers can withstand aggressive chemicals, which is essential in industries such as semiconductor manufacturing and chemical processing. The right materials enhance the operational lifespan of the pump, reducing maintenance costs and minimizing downtime.

Furthermore, advancements in diaphragm technology contribute to improvements in fluid transfer efficiency. Innovative designs and improved manufacturing techniques lead to pumps that operate with reduced energy consumption while maintaining high performance. This is particularly important in markets where energy efficiency is paramount, such as the metering pumps market, projected to reach $8.5 billion by 2028. As industries continue to seek out more efficient fluid transfer solutions, the significance of material selection and technology integration in diaphragm pumps will only grow, providing businesses with the opportunity to enhance their operational efficiency and sustainability.

Efficiency Metrics: Measuring Fluid Transfer Performance in Diaphragm Pumps

Diaphragm pumps have emerged as a crucial technology in fluid transfer systems, particularly in applications requiring hermetically sealed processes. The efficiency of these pumps can be significantly influenced by their design and operational features. For instance, diaphragm pumps operate without dynamic seals, which minimizes the potential for leaks and ensures consistent performance while handling various fluids. This unique construction not only enhances operational efficiency but also reduces the environmental impact by preventing contamination during fluid transfer.

In measuring fluid transfer performance, several efficiency metrics come into play. These may include flow rate, pressure stability, and overall energy consumption. The ability to maintain precise control over these parameters is vital for industries that depend on accurate fluid handling, such as chemical manufacturing or pharmaceuticals. By focusing on these efficiency metrics, industries can optimize the performance of diaphragm pumps, ensuring that they meet the stringent requirements of modern applications while also adhering to environmental standards.

Applications in Industry: Real-world Impact of Diaphragm Pumps on Fluid Management

Diaphragm pumps have gained significant traction across various industrial applications due to their exceptional capability in managing fluids. According to a report by MarketsandMarkets, the diaphragm pump market is projected to reach $3.5 billion by 2025, driven mainly by industries such as water and wastewater treatment, chemical processing, and pharmaceuticals. These pumps excel in handling corrosive and viscous fluids, making them indispensable in chemical manufacturing, where fluid integrity and transfer efficiency are crucial.

Moreover, diaphragm pumps play a vital role in improving operational efficiency. A case study from a leading wastewater treatment facility demonstrated that upgrading to diaphragm pumps resulted in a 30% reduction in energy consumption and a 20% decrease in maintenance costs. This efficiency not only enhances productivity but also contributes to sustainability goals by minimizing waste and energy use. As industries continue to adopt advanced fluid management solutions, the role of diaphragm pumps will likely expand, ensuring essential processes operate smoothly and economically.

Related Posts

-

8 Key Advantages of Diaphragm Pumps: Efficiency and Reliability in Fluid Management

-

Ultimate Guide to Selecting the Right Hydraulic Diaphragm Pump for Your Industrial Needs

-

Understanding the Benefits of High Pressure Diaphragm Pumps in Industrial Applications

-

Understanding the Advantages of Hydraulic Diaphragm Pumps in Modern Industrial Applications

-

Understanding the Benefits of High Flow Hydraulic Pump in Modern Industrial Applications

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications